bare ground in metal box The metal parts on both receptacle and box are bare and free of rust, paint or other contaminants; you have removed the little paper/plastic "squares" that capture the receptacle's . Discover high-quality precision metal stamping parts and components at our website. Browse our extensive range and find the perfect solution for your manufacturing needs.

0 · wire for ground box

1 · no ground wires electrical box

2 · no ground wire for metal box

3 · metal box grounding clip

4 · metal box grounding

5 · grounding wire for metal box

6 · grounding pigtail metal box

7 · grounding outlet for metal box

McNICHOLS carries the largest inventory of Perforated Metal products in North America with a vast selection of sizes, gauges, and hole types available. In both high-end and industrial settings, Perforated Metal brings strength and style to .

Pay close attention - if the ears "bottom out" on the metal of the box, you do not need that ground wire. If they bottom-out against drywall, you need a ground. Unrelated, one .The metal parts on both receptacle and box are bare and free of rust, paint or other .

Simply retrofit the grounds. Run a bare #12 ground wire using the wiring methods . The metal parts on both receptacle and box are bare and free of rust, paint or other contaminants; you have removed the little paper/plastic "squares" that capture the receptacle's .Simply retrofit the grounds. Run a bare #12 ground wire using the wiring methods you see used on the NM cable, and entering the box through normal NM style . For EGCs and GECs, the NEC allows ground wire to be either insulated or bare in most applications. I'm not aware of any case where insulation is explicitly required by the NEC .

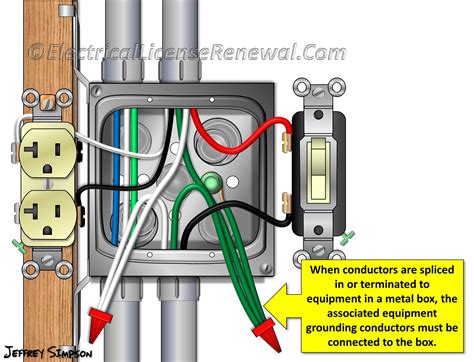

If a metal box is being used, best practice is to insert a green grounding screw into the threaded hole in the back of the box or enclosure. . In this video I will show you how to correctly bond a metal 4 square box. I want to be clear that you need to use a separate ground screw and a wire that i. Upon opening junction boxes in my basement I found the bare ground wires connected to the metal box itself. Is this proper, or should the be pigtailed inside the box? Or is it just a matter of preference?

The incoming ground wire or grounding conductor in the electrical box connects to the green ground screw on the receptacle and also, by extension or pigtailing, to the junction box if the electrical box is metal not plastic. Yes it technically does but NEC will tell you no. Get a green ground screw 10/32 thread and wrap a ground wire around it then fasten to box, theres already a hole in the box . Pay close attention - if the ears "bottom out" on the metal of the box, you do not need that ground wire. If they bottom-out against drywall, you need a ground. Unrelated, one more tip on the device-mounting screws.

wire for ground box

The metal parts on both receptacle and box are bare and free of rust, paint or other contaminants; you have removed the little paper/plastic "squares" that capture the receptacle's screws on the yoke; Then the hard-flush mating of those bare metal surfaces is an adequate grounding path for the receptacle, and you don't need a ground jumper.Simply retrofit the grounds. Run a bare #12 ground wire using the wiring methods you see used on the NM cable, and entering the box through normal NM style cable clamps (they can share with the NM). Inside each box, you terminate on the box's ground screw, a hole tapped 10-32.

For EGCs and GECs, the NEC allows ground wire to be either insulated or bare in most applications. I'm not aware of any case where insulation is explicitly required by the NEC for grounding conductors. It is an engineer's/installer's discretion to specify insulated grounding wire.

If a metal box is being used, best practice is to insert a green grounding screw into the threaded hole in the back of the box or enclosure. The equipment-grounding wires then connect to the screw, making the metal box part of the grounding system.

In this video I will show you how to correctly bond a metal 4 square box. I want to be clear that you need to use a separate ground screw and a wire that i.

Upon opening junction boxes in my basement I found the bare ground wires connected to the metal box itself. Is this proper, or should the be pigtailed inside the box? Or is it just a matter of preference?The incoming ground wire or grounding conductor in the electrical box connects to the green ground screw on the receptacle and also, by extension or pigtailing, to the junction box if the electrical box is metal not plastic. I have always believed when using a metal box with a self grounding receptacle, the ground wire from the incoming cable is connected to the ground screw in the back of the box. There is no need to run a wire from the box to the receptacle ground terminal as the self grounding feature makes that connection.

If you run the bare ground to the receptacle and try to use a self grounding receptacle to ground the box, you lose the box ground if you pull out the receptacle. Or down the road if someone changes the self grounding receptacle to a standard non- grounding, you lose the ground to the box. Pay close attention - if the ears "bottom out" on the metal of the box, you do not need that ground wire. If they bottom-out against drywall, you need a ground. Unrelated, one more tip on the device-mounting screws. The metal parts on both receptacle and box are bare and free of rust, paint or other contaminants; you have removed the little paper/plastic "squares" that capture the receptacle's screws on the yoke; Then the hard-flush mating of those bare metal surfaces is an adequate grounding path for the receptacle, and you don't need a ground jumper.

Simply retrofit the grounds. Run a bare #12 ground wire using the wiring methods you see used on the NM cable, and entering the box through normal NM style cable clamps (they can share with the NM). Inside each box, you terminate on the box's ground screw, a hole tapped 10-32. For EGCs and GECs, the NEC allows ground wire to be either insulated or bare in most applications. I'm not aware of any case where insulation is explicitly required by the NEC for grounding conductors. It is an engineer's/installer's discretion to specify insulated grounding wire. If a metal box is being used, best practice is to insert a green grounding screw into the threaded hole in the back of the box or enclosure. The equipment-grounding wires then connect to the screw, making the metal box part of the grounding system.

In this video I will show you how to correctly bond a metal 4 square box. I want to be clear that you need to use a separate ground screw and a wire that i. Upon opening junction boxes in my basement I found the bare ground wires connected to the metal box itself. Is this proper, or should the be pigtailed inside the box? Or is it just a matter of preference?The incoming ground wire or grounding conductor in the electrical box connects to the green ground screw on the receptacle and also, by extension or pigtailing, to the junction box if the electrical box is metal not plastic.

I have always believed when using a metal box with a self grounding receptacle, the ground wire from the incoming cable is connected to the ground screw in the back of the box. There is no need to run a wire from the box to the receptacle ground terminal as the self grounding feature makes that connection.

no ground wires electrical box

facom metal tool box

factory supply cylinder end cap cnc precision machining

fan rated electrical round box

no ground wire for metal box

The ability to produce and supply these CNC turned parts on a large scale – or better yet, wholesale, entails several strategic benefits that manufacturers can leverage. Economies of .

bare ground in metal box|metal box grounding clip