can 555 stepper motor driver work on cnc machine You can't use that driver board with a 555 timer, it requires four inputs from a suitable MCU (see the A4983 data sheet). You might be able to . A smoky, burning smell can be lovely when it's coming from your fireplace, but otherwise, it's something to be worried about.

0 · stepper motor timer

1 · stepper motor lm555 timer

2 · lm555 stepper motor

3 · cnc stepper wire sizes

4 · cnc stepper motor wiring diagram

5 · 555 timer for stepper motor

Galvanized steel is a type of steel that has been coated with a metallic layer to protect the base steel substrate from corrosion. Types of galvanized coatings include zinc (Zn), aluminum (Al), .

I have seen several people with joystick type controls, but those probably rely on a computer connection. I am using a simple 555 timer circuit with a variable frequency and a spdt switch to control the speed of movement. This goes into the "step" line of the driver board. You can't use that driver board with a 555 timer, it requires four inputs from a suitable MCU (see the A4983 data sheet). You might be able to . Some CNC machines use two motors driven on a single axis. If an unused motor output is available on the Buildbotics Controller, simply assign . We've had a few inquiries regarding stepper motor selection for CNC build projects and thought we'd put together a handy guide on demystifying the motor, driver and power supply relationship to better help you make the .

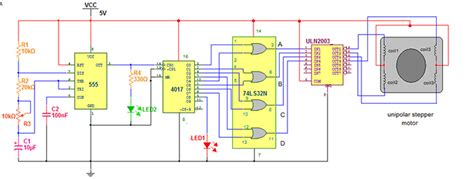

And here I've put together a circuit that I think is the absolute cheapest and easiest way to control stepper motors with step and direction signals. It works with many of the free or low cost softwares that produce step and direction signals . Yes, you could hook a stepper motor directly to drive wheels on some sort of shuttle. CNC controllers normally have a setting for inches/step or some equivalent. If you set . Wire to stepper motor driver board. Be careful NOT to ground the negative lead at the power supply (and don't use a power supply that won't let you float ground). Otherwise, the .The drive components are the mechanical components that "drive" the CNC machine along its axis. The most common components associated with a drive system, are the motors, lead or ball screw, or rack and pinions.

The page for the CNC shield says I also need to get "Pololu A4988 compatible stepper drivers". However, on a previous post about these motors I was advised that "the . A driver capable of delivering 6A per phase will be fine for a 4.2A motor, so long as you can set the current accordingly - whether you want the full 4.2A or a lower value. It will be . I have seen several people with joystick type controls, but those probably rely on a computer connection. I am using a simple 555 timer circuit with a variable frequency and a spdt switch to control the speed of movement. This goes into the "step" line of the driver board. You can't use that driver board with a 555 timer, it requires four inputs from a suitable MCU (see the A4983 data sheet). You might be able to design some logic to drive it from the 555, but it won't be easy.

Can someone recommend me a stepper driver with motors. I recommend Rutex drivers. Pay attention to the inductance of the motors. If the square root of the inductance isn't 1/32nd of the voltage you're supplying to it (or at least close) then performance at high speed (which you need for cutting wood) will be compromised. So far I have determined that I will use a shielded twisted pair 22awg for the connection between the motor drivers and the motors. I now need to figure out what size and type of wire to use for all the other connections. Can I use 22awg for all those as well? Which connections need shielding?

Some CNC machines use two motors driven on a single axis. If an unused motor output is available on the Buildbotics Controller, simply assign the second motor output to the same axis and connect the second axis motor to the second output. We've had a few inquiries regarding stepper motor selection for CNC build projects and thought we'd put together a handy guide on demystifying the motor, driver and power supply relationship to better help you make the right choices in selecting the right gear for your build.And here I've put together a circuit that I think is the absolute cheapest and easiest way to control stepper motors with step and direction signals. It works with many of the free or low cost softwares that produce step and direction signals through the parallel printer port. Yes, you could hook a stepper motor directly to drive wheels on some sort of shuttle. CNC controllers normally have a setting for inches/step or some equivalent. If you set that correctly, the machine should drive the motors "correctly". But No, this not likely to give you the output you want.

Wire to stepper motor driver board. Be careful NOT to ground the negative lead at the power supply (and don't use a power supply that won't let you float ground). Otherwise, the voltage drop accross the negative lead causes ground current loops .The drive components are the mechanical components that "drive" the CNC machine along its axis. The most common components associated with a drive system, are the motors, lead or ball screw, or rack and pinions. I have seen several people with joystick type controls, but those probably rely on a computer connection. I am using a simple 555 timer circuit with a variable frequency and a spdt switch to control the speed of movement. This goes into the "step" line of the driver board.

You can't use that driver board with a 555 timer, it requires four inputs from a suitable MCU (see the A4983 data sheet). You might be able to design some logic to drive it from the 555, but it won't be easy. Can someone recommend me a stepper driver with motors. I recommend Rutex drivers. Pay attention to the inductance of the motors. If the square root of the inductance isn't 1/32nd of the voltage you're supplying to it (or at least close) then performance at high speed (which you need for cutting wood) will be compromised. So far I have determined that I will use a shielded twisted pair 22awg for the connection between the motor drivers and the motors. I now need to figure out what size and type of wire to use for all the other connections. Can I use 22awg for all those as well? Which connections need shielding?

Some CNC machines use two motors driven on a single axis. If an unused motor output is available on the Buildbotics Controller, simply assign the second motor output to the same axis and connect the second axis motor to the second output. We've had a few inquiries regarding stepper motor selection for CNC build projects and thought we'd put together a handy guide on demystifying the motor, driver and power supply relationship to better help you make the right choices in selecting the right gear for your build.And here I've put together a circuit that I think is the absolute cheapest and easiest way to control stepper motors with step and direction signals. It works with many of the free or low cost softwares that produce step and direction signals through the parallel printer port. Yes, you could hook a stepper motor directly to drive wheels on some sort of shuttle. CNC controllers normally have a setting for inches/step or some equivalent. If you set that correctly, the machine should drive the motors "correctly". But No, this not likely to give you the output you want.

cnc turning spare parts

Wire to stepper motor driver board. Be careful NOT to ground the negative lead at the power supply (and don't use a power supply that won't let you float ground). Otherwise, the voltage drop accross the negative lead causes ground current loops .

stepper motor timer

stepper motor lm555 timer

lm555 stepper motor

Springback is a semipredictable factor when working with sheet metal. Knowing how to forecast it will allow you to make better tooling selections, especially for profound-radius bends in which springback can exceed 40 degrees.

can 555 stepper motor driver work on cnc machine|stepper motor timer