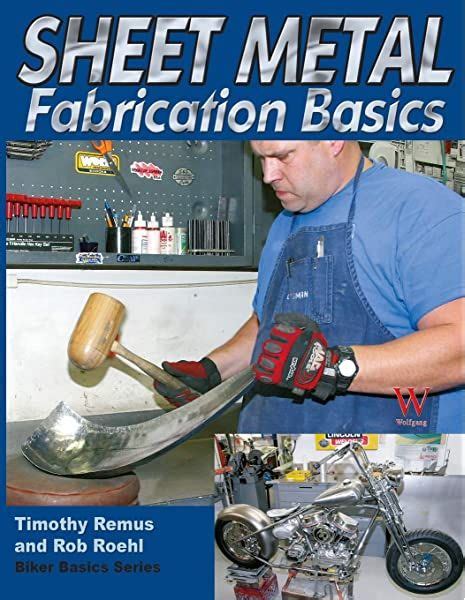

sheet metal fabrication hand book Develop the skills you need to build your own sheet metal parts! Expert customizer Tim Remus combines his knowledge with metal-workers Steve Davis, Bob Monroe, Steve . This 12" x 8" heavy duty shelf bracket is made from high quality steel and features a white powder coat finish. This shelf bracket is designed to work great for shelving systems for the home, shop, garage, or business. Simply assemble multiple brackets using screws, bolts, or nails (sold separately) and a section of shelving.

0 · ultimate sheet metal fabrication

1 · steel fabrication books

2 · sheet metal workbooks

3 · sheet metal layout books

4 · sheet metal hand book

5 · sheet metal fabrication paperback pdf

6 · sheet metal fabrication book pdf

7 · sheet metal design book

$37.43

ultimate sheet metal fabrication

Author of HP's award-winning Metal Fabricator's Handbook, Fournier packs decades of experience designing and shaping sheet metal components for Indy cars, drag .Develop the skills you need to build your own sheet metal parts! Expert .

Detailed chapters cover the right tool for the job, materials, welding, repairs, building from scratch and finish work, plus tips on how to repair and modify an existing part .

hager junction box screwfix

Develop the skills you need to build your own sheet metal parts! Expert customizer Tim Remus combines his knowledge with metal-workers Steve Davis, Bob Monroe, Steve . This volume addresses all methods of sheet metal fabrication technologies, selection of equipment and die materials, specification of forming practices for specific alloys, and new techniques for process design and control. Master the art of sheet metal fabrication with our comprehensive handbook. Learn about the latest technology and techniques for cutting, bending, and finishing sheet metal projects with precision and efficiency.Author of HP's award-winning Metal Fabricator's Handbook, Fournier packs decades of experience designing and shaping sheet metal components for Indy cars, drag race cars, road .

Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a .features into a flat sheet. Some of the options are counter sinks, offsets, card guides, embosses, draws, wipe forms, part markings, lettering, lances, half-shears, and weld projections.

Imagine transforming a flat sheet of aluminum alloy into an attractive hood scoop. Or designing and making your own aluminum wheel tubs, floorpan and dashboard for your street machine. How about learning to design and build your own body panels, manifolds, brackets and fuel tanks? These are just a few of the many tips and techniques shared by master metal craftsman Ron .Download UPTIVE's Sheet Metal Design Handbook PDF . . Why you should choose sheet metal fabrication; General Inquiries [email protected] (888) 467-7686. 2441 Commerce Drive Libertyville, IL 60048. 29 Victory Lane Poughkeepsie, NY 12603. 688 E .

Sheet Metal Fabrication Handbook – Forming How does a flat metal sheet transform into complex shapes and structures? This blog post delves into the intricate processes of sheet metal forming, including partial shearing, .- 2 - Forming Basics Press brake forming-The fundamental advantage of a press brake as a forming tool is its flexibility. By using standard vee-dies, cost savings can be realized through economical set-ups and run times on small lots and prototypes.Sheet metal fabrication’s vast construction applications are due to the durability, strength, high weather resistance, manufacturability, versatility, aesthetic qualities, and other beneficial properties of various sheet metals, including steel, aluminium, and copper. One of countless examples of sheet metal fabrication in the construction .Chapter 6.Formulas for Sheet Metal Layout and Fabrication 6.1 6.1 Sheet Metal Flat-Pattern Development and Bending / 6.8 6.2 Sheet Metal Developments,Transitions,and Angled Corner Flange Notching / 6.14 6.3 Punching and Blanking Pressures and Loads / 6.32 6.4 Shear Strengths of Various Materials / 6.32 6.5 Tooling Requirements for Sheet Metal .

Have you ever wondered how everyday metal objects get their polished finish or rust-resistant surfaces? This article explores the intricate world of surface treatments in sheet metal fabrication. From drawing and shot blasting to various plating methods, it delves into the techniques that transform raw metal into durable, aesthetically pleasing products. Winner of the prestigious Moto Award for "Best Technical How-to Book" in 1984, the Metal Fabricator's Handbook applies master metal craftsman Ron Fournier's unique metal fabricating skills—developed during years of building Indy cars, drag racers, stockers, custom show cars, and sports GT race cars. Covers MIG, TIG, arc- and gas-welding, fuel and oil .

Detailed information on how to form and shape sheet metal for competition, custom or restoration use. Chapters include hammer forming tools, terms and equipment, riveting techniques, layout, design and pattern-making. A great companion to the Metal Fabricator's Handbook. Author: Ron and Sue Fournier Pages: 144

Common engineering materials for laser cutting: 1. Laser cutting of metal materials: Almost all metal materials have a high reflectivity to infrared wave energy at room temperature, but CO 2 laser with a wavelength of 10.6μm has been successfully applied to laser cutting of many metals.. The initial absorption rate of metal to 10.6μm laser beam is only 0.5 .

Volume 14B on sheet forming is the second of two volumes on metalworking technology. This volume addresses all methods of sheet metal fabrication technologies, selection of equipment and die materials, specification of forming practices for specific alloys, and new techniques for process design and control. Professional Sheet Metal Fabrication is the number-one resource for sheet metal workers old and new. Join veteran metalworker Ed Barr as he walks you through the ins and outs of planning a sheet metal project, acquiring the necessary tools and resources, doing the work, and adding the perfect finishing touches for a seamless final product.ASM Handbook, Volume 14B: Metalworking: Sheet Forming is a comprehensive reference on sheet metal forming and fabrication that provides state-of-the-art reference information for product and production engineers. Coverage addresses all methods of sheet metal fabrication technologies, selection of equipment and die materials, specification of forming practices for . What are the advantages of precision sheet metal fabrication? Precision sheet metal fabrication offers high-quality, durable products with precise specifications. How long does precision sheet metal fabrication take? The time .

The craft of hand-forming sheet metal into compound curves is fast becoming a lost art. Author Eddie Paul is a master at sheet metal fabrication and in this book shares with readers the techniques to shape their own sheet .Sheet Metal; Sheet Metal. Manuals and References for Sheet Metal. View as Grid List. . Metal Fabrication: A Practical Guide 4th Edition. Special Price 3.45 Regular Price 4.95. Quickview. . Machinery's Handbook Pocket . Metal fabrication : a practical guide by O'Con, Robert L. Publication date 2015 Topics Metal-work, Travail des métaux, metalworking, Metals Forming Publisher Rockford, Ill. : Fabricators & Manufacturers Association, International Collection internetarchivebooks; printdisabled Contributor Internet Archive Language

Get an overview to sheet metal fabrication from the different types of sheet metal fabrication, to design best practices, materials, finishings and fastenings. 20% off your first order. Save up to ,000/€1,000. Covers the basics of metal fabrication processes, including primary mill fabrication, casting, bulk deformation, forming, machining, heat treatment, finishing and coating, and powder metallurgy. . abrasive acid alloying elements alloys annealing applications approximately ASM Handbook ASM International atomization austenite . plating powder .

Sheet Metal Fabrication Eddie Paul,2008-03-15 Sheet metal fabrication--from fins and fenders to art--with all the necessary information on tools, preparations, materials, forms, mock-ups, and much more. Die Design Handbook David Alkire Smith,1990 Whether you're involved in a highly specialized operation, or need How can we ensure secure and durable connections in sheet metal fabrication? This article explores various joining and fastening techniques, including TOX riveting, welding, and nail riveting. You'll discover the pros and cons of each method, practical applications, and how they contribute to the strength and integrity of metal structures. Dive in to understand .

http://www.machineryhouse.com.au/L3455Professional Sheet Metal Fabrication BookFor more information on this machine, please visit:Hare and Forbes Machineryho.In metal fabrication, fabricators create metal parts from raw source metals like steel, copper or aluminium.They’ll use methods like cutting, punching, bending, and welding to fabricate the parts needed for a project. Sheet metal fabrication specifically uses all of the same processes, but only flat metal sheets are used as the source to create the products.

This comprehensive guide delves into the intricacies of custom sheet metal fabrication, covering a wide array of topics to provide a holistic understanding of this specialized field. Defining Custom Sheet Metal Fabrication. Custom sheet metal fabrication encompasses the cutting, shaping, and assembly of metal sheets to create products with .

A: Trusted manufacturers offer reliable OEM metal fabrication services. Q: What is precision sheet metal fabrication? A: It is the process of shaping and manipulating sheet metal with high accuracy. Q: How can I find a reputable OEM metal fabrication company? A: Research online, read reviews, and ask for recommendations from industry professionals.Technical standards and manuals developed by SMACNA members have worldwide acceptance by the construction and code community, as well as local and national government agencies. ANSI, the American National Standards Institute, has accredited SMACNA as a standards-setting organization. SMACNA standards and manuals address all facets of the sheet metal and .

half inch electrical box rubber caps

Holds rods with up to an 1.3 inches diameter. Closet Pole Support Bracket include portions for supporting both a clothes rod and a shelf. Easy to install, both for closet and wall bracket. sturdy, scratch resistant, very sturdy and solid, made of heavy duty metal.

sheet metal fabrication hand book|sheet metal fabrication paperback pdf