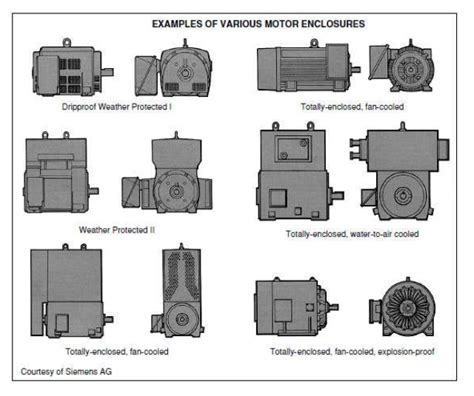

electric motor enclosure parts The article discusses motor enclosure types as outlined by the NEMA standards, focusing on open and totally enclosed motors. Open motors feature ventilating openings for cooling, while totally enclosed motors restrict air exchange. Box plot, a.k.a Box and Whisker plot, is a pictorial representation of continuous data. Box plots show the max, min, median, interquartile range Q1, Q3, and outlier. Rectangles are drawn to show the second and the third quartiles. And there is a vertical line that shows the median value.

0 · types of electric motor enclosures

1 · totally enclosed motor

2 · totally enclosed fan cooled motor

3 · totally enclosed air over motor

4 · open drip proof motors

5 · odp enclosure vs tefc

6 · motor enclosure opsb meaning

7 · motor enclosure odp vs tefc

United Metals is a full-service metal fabricator providing precision metal fabrication services for various industries across the USA. We operate high-speed machines and utilize state-of-the-art technology to provide cost-effective metal fabricating solutions that meet your needs.

The National Electrical Manufacturers Association (NEMA) has established over 20 different enclosure types under their MG1 standards, which categorize motors as open, totally enclosed, or sealed windings designs.

pull and junction boxes

The article discusses motor enclosure types as outlined by the NEMA standards, focusing on open and totally enclosed motors. Open motors feature ventilating openings for cooling, while totally enclosed motors restrict air exchange.Understanding these types can help you make informed decisions, ensuring optimal performance, safety, and durability of your electric motors. 1. Open Drip Proof (ODP) Enclosures. ODP enclosures are designed for general-purpose .Electric Motors are available in various types of enclosures, each providing different levels of protection and cooling. The enclosure type is selected based on application to protect the motor's bearings, windings, and other parts from .

types of electric motor enclosures

Shop industrial electric motor control products, components & accessories for AC and DC motors, like soft starters, contactors, relays, DIN rail terminal blocks & terminal strips, disconnect terminals, ground clamps, distribution blocks, cord . NEMA enclosure standard for electrical motors. The enclosures of electrical motors are standardized by NEMA (National Electrical Manufacturers Association) as: Ventilation .

Finding the most suitable electric motor enclosure type for your application can save you money, enhance motor performance, and extend the life of your motor. But how do you know what enclosure type you need?• get more exact search results using enclosure & frame • fm searches all critical mounting dimensions • view results in best match order NEMA standards MG1-1.25 through 1.27 define more than 20 types of enclosures under the categories of open machines, totally enclosed machines, and machines with encapsulated or sealed windings. The 7 most common types of . The National Electrical Manufacturers Association (NEMA) has established over 20 different enclosure types under their MG1 standards, which categorize motors as open, totally enclosed, or sealed windings designs.

totally enclosed motor

totally enclosed fan cooled motor

The article discusses motor enclosure types as outlined by the NEMA standards, focusing on open and totally enclosed motors. Open motors feature ventilating openings for cooling, while totally enclosed motors restrict air exchange.

This article will review four major enclosure options (ODP, WPII, TEWAC and TEAAC) for large- and medium-size electric motors (3,000 horsepower [hp] or larger) and a guide for selecting proper motor enclosure types while considering cooling methods, pros/cons, motor size, cost, reliability and site environments.

Understanding these types can help you make informed decisions, ensuring optimal performance, safety, and durability of your electric motors. 1. Open Drip Proof (ODP) Enclosures. ODP enclosures are designed for general-purpose motors where the .

Electric Motors are available in various types of enclosures, each providing different levels of protection and cooling. The enclosure type is selected based on application to protect the motor's bearings, windings, and other parts from dust, moisture, chemicals, mechanical damage, and other contaminants.Shop industrial electric motor control products, components & accessories for AC and DC motors, like soft starters, contactors, relays, DIN rail terminal blocks & terminal strips, disconnect terminals, ground clamps, distribution blocks, cord & cable, programmable logic controllers, PLC, human-machine interface, HMI, NEMA enclosures, and motor . NEMA enclosure standard for electrical motors. The enclosures of electrical motors are standardized by NEMA (National Electrical Manufacturers Association) as: Ventilation openings in shield and/or frame prevents drops of liquid from falling into motor within up to 15 degree angle from vertical.Finding the most suitable electric motor enclosure type for your application can save you money, enhance motor performance, and extend the life of your motor. But how do you know what enclosure type you need?

• get more exact search results using enclosure & frame • fm searches all critical mounting dimensions • view results in best match order NEMA standards MG1-1.25 through 1.27 define more than 20 types of enclosures under the categories of open machines, totally enclosed machines, and machines with encapsulated or sealed windings. The 7 most common types of .

The National Electrical Manufacturers Association (NEMA) has established over 20 different enclosure types under their MG1 standards, which categorize motors as open, totally enclosed, or sealed windings designs.The article discusses motor enclosure types as outlined by the NEMA standards, focusing on open and totally enclosed motors. Open motors feature ventilating openings for cooling, while totally enclosed motors restrict air exchange.

This article will review four major enclosure options (ODP, WPII, TEWAC and TEAAC) for large- and medium-size electric motors (3,000 horsepower [hp] or larger) and a guide for selecting proper motor enclosure types while considering cooling methods, pros/cons, motor size, cost, reliability and site environments.Understanding these types can help you make informed decisions, ensuring optimal performance, safety, and durability of your electric motors. 1. Open Drip Proof (ODP) Enclosures. ODP enclosures are designed for general-purpose motors where the .Electric Motors are available in various types of enclosures, each providing different levels of protection and cooling. The enclosure type is selected based on application to protect the motor's bearings, windings, and other parts from dust, moisture, chemicals, mechanical damage, and other contaminants.

Shop industrial electric motor control products, components & accessories for AC and DC motors, like soft starters, contactors, relays, DIN rail terminal blocks & terminal strips, disconnect terminals, ground clamps, distribution blocks, cord & cable, programmable logic controllers, PLC, human-machine interface, HMI, NEMA enclosures, and motor .

totally enclosed air over motor

NEMA enclosure standard for electrical motors. The enclosures of electrical motors are standardized by NEMA (National Electrical Manufacturers Association) as: Ventilation openings in shield and/or frame prevents drops of liquid from falling into motor within up to 15 degree angle from vertical.Finding the most suitable electric motor enclosure type for your application can save you money, enhance motor performance, and extend the life of your motor. But how do you know what enclosure type you need?

open drip proof motors

Vintage Union Steel Tackle Tool Utility Box Pat numbers 161360 & 3171566. Used showing minor signs of use and in excellent condition for age, some faded paint on the back of tool box. .

electric motor enclosure parts|motor enclosure odp vs tefc