electric box clearance The site is secure. The https:// ensures that you are connecting to the official website . $9.98

0 · working clearance for electrical panel

1 · residential electrical panel clearance requirements

2 · osha electrical panel clearance requirements

3 · nec electrical panel clearance requirements

4 · electrical panel clearances

5 · electrical panel clearance requirements

6 · clearances around electrical panels

7 · clearance required around electrical panel

CNC grinding, an incredible manufacturing innovation, marries computer control and grinding precision. This field, rich with diverse machine types and process intricacies, offers much to learn for both the novice and the seasoned machinist.

Electric equipment shall be free from recognized hazards that are likely to cause death or serious physical harm to employees. Safety of equipment shall be determined using the following considerations: Suitability for installation and use in conformity with the provisions of this subpart;The site is secure. The https:// ensures that you are connecting to the official website .The site is secure. The https:// ensures that you are connecting to the official website . When looking into electrical panel clearance safety, you need to start by looking at the requirements put in place by the national electric code, or NEC. The relevant section of the .

There is not a standard electrical code requirement that gives the minimum clearance distance between an electrical panel and a plumbing fixture, but you can figure a minimum distance .

OSHA and the National Electrical Code (NEC) specify that electrical panels must have a minimum clearance of 36 inches in depth, 30 inches in width, and 78 inches in height. These dimensions .For equipment designed for floor mounting, clearance between top surfaces and adjacent surfaces shall be provided to dissipate rising warm air. Electrical equipment provided with . An electrical panel clearance refers to the minimum distance required between an electrical panel and any surrounding objects or surfaces. This clearance is mandated by safety regulations to prevent electrical hazards .NEC 110.26 and 29 CFR 1910.303(g)(1) require sufficient working space and clearance around electric equipment.

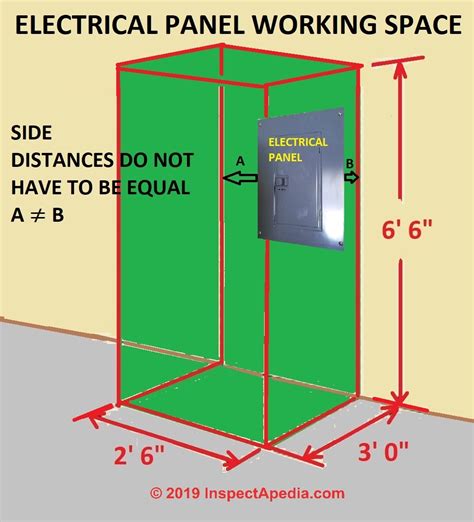

A minimum clearance reduces risk and makes it easier for electricians to work with electrical panels, ensuring that there isn’t any object near the breaker box, which might result in a dangerous situation. The National Electrical Code [NEC 110.26 (A)(1&2)] requires a clear area for access and working in front of an electric panel that is 2.5 feet (30”) wide, 3 feet (36”) deep, and 6.5 .Electric equipment shall be free from recognized hazards that are likely to cause death or serious physical harm to employees. Safety of equipment shall be determined using the following considerations: Suitability for installation and use in conformity with the provisions of this subpart;Whether you’re updating an electrical panel or installing a new one, ensuring that there’s plenty of room plays a crucial role in ensuring the safe operation of your electrical system. The working clearance is the minimum amount of space required to access the panel safely.

metal fabrication training in indiana

When looking into electrical panel clearance safety, you need to start by looking at the requirements put in place by the national electric code, or NEC. The relevant section of the national electric code here is NEC 110.26.There is not a standard electrical code requirement that gives the minimum clearance distance between an electrical panel and a plumbing fixture, but you can figure a minimum distance from plumbing to panel by at least following the working space requirements.OSHA and the National Electrical Code (NEC) specify that electrical panels must have a minimum clearance of 36 inches in depth, 30 inches in width, and 78 inches in height. These dimensions ensure sufficient space for workers to safely and efficiently perform maintenance tasks.

For equipment designed for floor mounting, clearance between top surfaces and adjacent surfaces shall be provided to dissipate rising warm air. Electrical equipment provided with ventilating openings shall be installed so that walls or other obstructions do not prevent the free circulation of air through the equipment. An electrical panel clearance refers to the minimum distance required between an electrical panel and any surrounding objects or surfaces. This clearance is mandated by safety regulations to prevent electrical hazards such as electrocution, fire, or equipment damage.NEC 110.26 and 29 CFR 1910.303(g)(1) require sufficient working space and clearance around electric equipment.

A minimum clearance reduces risk and makes it easier for electricians to work with electrical panels, ensuring that there isn’t any object near the breaker box, which might result in a dangerous situation.

The National Electrical Code [NEC 110.26 (A)(1&2)] requires a clear area for access and working in front of an electric panel that is 2.5 feet (30”) wide, 3 feet (36”) deep, and 6.5 feet (78”) high for a regular residential 120/240-volt panel.Electric equipment shall be free from recognized hazards that are likely to cause death or serious physical harm to employees. Safety of equipment shall be determined using the following considerations: Suitability for installation and use in conformity with the provisions of this subpart;Whether you’re updating an electrical panel or installing a new one, ensuring that there’s plenty of room plays a crucial role in ensuring the safe operation of your electrical system. The working clearance is the minimum amount of space required to access the panel safely. When looking into electrical panel clearance safety, you need to start by looking at the requirements put in place by the national electric code, or NEC. The relevant section of the national electric code here is NEC 110.26.

There is not a standard electrical code requirement that gives the minimum clearance distance between an electrical panel and a plumbing fixture, but you can figure a minimum distance from plumbing to panel by at least following the working space requirements.OSHA and the National Electrical Code (NEC) specify that electrical panels must have a minimum clearance of 36 inches in depth, 30 inches in width, and 78 inches in height. These dimensions ensure sufficient space for workers to safely and efficiently perform maintenance tasks.For equipment designed for floor mounting, clearance between top surfaces and adjacent surfaces shall be provided to dissipate rising warm air. Electrical equipment provided with ventilating openings shall be installed so that walls or other obstructions do not prevent the free circulation of air through the equipment.

working clearance for electrical panel

residential electrical panel clearance requirements

An electrical panel clearance refers to the minimum distance required between an electrical panel and any surrounding objects or surfaces. This clearance is mandated by safety regulations to prevent electrical hazards such as electrocution, fire, or equipment damage.NEC 110.26 and 29 CFR 1910.303(g)(1) require sufficient working space and clearance around electric equipment. A minimum clearance reduces risk and makes it easier for electricians to work with electrical panels, ensuring that there isn’t any object near the breaker box, which might result in a dangerous situation.

metal fabrication trade publications

Legrand Wiremold V5747-2 Metal Raceway for Extending Power, 500 and 700 Series, 2 Gang Switch and Outlet Box, 1 3/8" Deep, Ivory (1 Pack) - Power Strips And Multi .

electric box clearance|electrical panel clearances