how to start a sheet metal part in solidworks You can design a sheet metal part on its own without any references to the parts it will enclose, you can design the part in the context of an assembly that contains the enclosed components, . Use a dc welder and elektrode set on negative polarity. When using dc current you get about 70% of the heat on the positive and 30 % on the negative. So DCEN is good on thin metall and big gaps. With a AC welder you get 50/50. Other than that use a smal rod and you can also go downhill depending on witch kind of rod u are using.

0 · solidworks sheet metal template

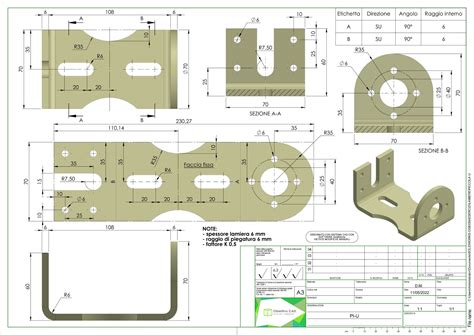

1 · solidworks sheet metal pdf

2 · solidworks sheet metal part drawing

3 · solidworks sheet metal drawing pdf

4 · solidworks sheet metal download

5 · solidworks sheet metal basics

6 · sheet metal drawing in solidworks

7 · sheet metal 3d sketch solidworks

basics of how to solder using muriatic acid, cFLUX, map gas, and tri-bar solder.

How to Start a Sheet Metal Part in SolidWorks LET'S CONNECT! Google+ https://plus.google.com/+Cati1/posts Facebook / catisolidworks Twitter / catisolidworks Linkedin.You can design a sheet metal part on its own without any references to the parts it will enclose, you can design the part in the context of an assembly that contains the enclosed components, . By the end of this tutorial, you'll be well-equipped to design your own sheet metal components confidently in SolidWorks. Music: Inspire by Wavecont https://protunes.net Video Link: •. How to Use SolidWorks Base Flange | SolidWorks SheetMetal Tutorial #1. Base Flange is first and basic step used to start sheet metal model. It is applicable one per part file. .

Learn the essentials of sheet metal part design in SolidWorks with this comprehensive tutorial! This video is perfect for designers and engineers who want to. SOLIDWORKS 3D allows you to quickly create sheet metal part designs using a simple design process, saving you time and development costs, thanks to specific sheet metal features. We can use these features to create .Flattening and Folding the Part. You can flatten all the bends of a sheet metal part at once. Creating a Sheet Metal Drawing. Now create a drawing of the sheet metal part. Start with an . Sheet metal parts are made with a constant thickness. They start out as one flat sheet and then are cut and bent to make the final product. When it comes to creating a sheet metal part in SOLIDWORKS you have two choices .

Under Tangent edges, select Visible, and click OK. Click Make Drawing from Part/Assembly (Standard toolbar) or File > Make Drawing from Part, then click OK to open a drawing sheet. .Adding Walls to Sheet Metal Parts. Creating Elliptical Bends. You can sketch an ellipse and a create sheet metal part that has elliptical bends. Drawings of Sheet Metal Parts. When you create a drawing of your sheet metal part, a flat pattern is automatically created. Drawings of sheet metal parts can also contain views of the bent sheet metal . There are a few steps that need to be taken to start a sheet metal part in Solidworks. First of all, you need to select a sheet metal part and make a few . First of all, you need to select a sheet metal part and make a few. Email: [email protected] Services. CNC Machining; 3D Printing; Vacuum Casting; Sheet Metal Part; Our Works; About; Blog .I'm relatively new to sheetmetal in SW and about to start a part that will be made up of several different unique pieces of sheetmetal riveted, and bonded together, maybe welded in sections if it comes to that.

Adding Walls to Sheet Metal Parts. Creating Elliptical Bends. You can sketch an ellipse and a create sheet metal part that has elliptical bends. Drawings of Sheet Metal Parts. When you create a drawing of your sheet metal part, a flat pattern is automatically created. Drawings of sheet metal parts can also contain views of the bent sheet metal .Start a new part > create a base flange > set the sheet metal parameters to whatever you want > delete the base flange feature and any sketches > save as part template > enjoy your new defaults Extra tip: K factor is a dimension that can be used in custom properties. The syntax is "D2@[email protected]". I have my templates set so . Solidworks 2022 Sheet Metal Tutorial - Design and Assembly for BeginnersHi and welcome back. Today I am going to show you how to design and assemble a simple.

In this week's Tech Tip, we show you how you can fix a standard error in the sheet metal component in SOLIDWORKS. Follow us on Social Media to get the latest.

solidworks sheet metal template

Sheet Metal Design in SolidWorks for Beginners | Step-by-Step TutorialIn this comprehensive SolidWorks tutorial, we'll walk you through the fundamentals of s. We will need 7 sheets of material and produce 15 parts per sheet, except the last sheet with only 10 parts. Scrap estimation is 39.41%. If we make any changes to our component, sheet size, quantity, or offsets, we can quickly update our estimate. In this case, I’ve increased the width of the part and increased both the part and sheet offsets .The tooling would be linked to inside radius on sheet metal parts. Everything I can see online details how to do it by adding custom properties in the part first every time. . Best. Top. New. Controversial. Old. Q&A. Add a Comment. lousainfleympato • The custom properties that you start with are defined by the part template. Add the ones .

So I'm doing this as a sheet metal part, so that I can flatten my curved surfaces. Which is fine. I've used sheet metal parts to create corrugated boxes, etc. But I'm stuck here. The top of my pedal car is flat and tapers off in the back. That's all good. The bottom has the same taper but curves up towards the back. All good here too. we will learn sheet metal basic features like Base Flange,Edge Flange ,Sketched bend and Extruded Cut in Solidworks sheet metal.1)Solidworks tutorial for Beg. Without getting into the sheet metal module, first model each flat portion, and then 'loft' between them, using 'normal to profile' for the start/end constraints. After that, you can select one of the flat surfaces and 'insert bends' to convert .Use insert bends and select one of the straight edges as the fixed edge. This part is a cone though so a simple conversion isn't going to work. The way I would do this is to use the imported geometry as a reference to make a native sheet metal part using lofted bend.

76K subscribers in the SolidWorks community. ALL posts related to SOLIDWORKS are welcome. . start of bend, offset bend. Each positions the bend radius differently relative to the sketch edge. . You can try using sheet .I would personally start with one sheet size larger. Or smaller scale. That way the part can "breathe". Sorry just looked at the sheet again. Start by shrinking the iso view. It should just be there to help understand the drawing at first glance. .What I do is check the "Override default parameters" on the sheet metal feature. Then, while in context of the assembly, I double click on the body. This will show your sheet metal dimensions (thickness, radius, and K factor for me). Then you can modify the thickness by double clicking it, and then link it to your assembly level custom property.Now create a drawing of the sheet metal part. Start with an isometric view of the folded model, and then add a view of the unfolded model. Click Options (Standard toolbar).; On the System Options tab, click Drawings > Display Style.; Under Tangent edges, select Visible, and click OK.; Click Make Drawing from Part/Assembly (Standard toolbar) or File > Make Drawing from Part, .

Stp files don't include the necessary information to convey that it is a sheet metal part. When you make sheet metal parts in OnShape or Solidworks, more information than just the 3D model is being created and processed. It's how these programs know that a bend is impossible or how to unfold. You need a more descriptive file or remake the model. Then start dragging the parts around until they fit best on the sketch. Adding a few mates to keep everything on the same reference plane, or to fine tune an angle or position would help. A drawing of the assembly can be made, then the drawing can be saved as a dxf/dwg file.Sheet metal parts are generally used as enclosures for components or to provide support to other components. You can design a sheet metal part on its own without any references to the parts it will enclose, you can design the part in the context of an assembly that contains the enclosed components, or you can design the part within another part document in a multibody .

solidworks sheet metal pdf

Designing a part with sheet metal-specific features uses fewer features and editing tools, and eliminates the use of the rollback bar. The sheet metal-specific features make it easier and faster to create a sheet metal part than designing a part, then converting it to sheet metal.If the cut feature outline isn't present on the side of the part you've selected as the Fixed Entity in Convert to Sheet Metal, it won't be transferred to the Sheet Metal part. That's also the case with countersunk and counterbored holes, convert sheet metal will transfer the outline that is on the fixed face to the sheet metal part. It is often much easier and more efficient to work on sheet metal parts in the flat. These tools will help us to do that. . Let’s start with the Unfold tool. SOLIDWORKS will prompt us to choose a Fixed Face. Ensure that the Fixed Face chosen remains constant when using the Fold and Unfold tools. I prefer to use one of the main faces of the .Learn the essentials of sheet metal part design in SolidWorks with this comprehensive tutorial! This video is perfect for designers and engineers who want to.

Splitting Sheet Metal Parts. You can create a multibody sheet metal part using any command that creates multiple bodies from a single body. Inserting a Part to Create a Multibody Sheet Metal Part. The Insert Part command lets you create a multibody sheet metal part by inserting a sheet metal body into another sheet metal part. Duplicating .

How to Prepare Rolled Sheet Metal Parts in SolidWorks. Let’s walk through the steps necessary to flatten a rolled sheet metal part in Solidworks to prepare it for laser cutting. Step 1: Use “Cut-Extrude” to make a parting line in your rolled part. First, open your transition part file and make a parting line which will be the seam when .

solidworks sheet metal part drawing

solidworks sheet metal drawing pdf

To master the art of welding sheet metal using TIG and MIG, you need to follow some tips for successful welding. You can start by choosing the right filler metal, controlling heat input, managing distortion, and ensuring proper weld joint fit-up, to get the best results.

how to start a sheet metal part in solidworks|sheet metal 3d sketch solidworks