electrical enclosures elevation standard Standard Interpretations: Display all referenced documents. Scroll to Top. . Moisture may gain access to an electrical panel box via the following: Poor or damaged seals around the electric meter. Rainwater can seep through gaps and cracks in the seal. Capillary action can allow moisture into the enclosure even if the access point is located underneath. Reinforcing fabrics.

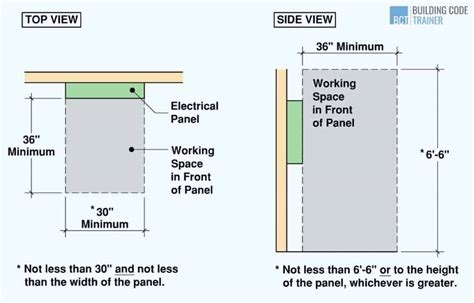

0 · working space for electrical equipment

1 · osha unguarded parts elevation requirements

2 · osha electrical panel clearance requirements

3 · osha electrical enclosure requirements

4 · electrical equipment installation requirements

5 · electrical equipment installation regulations

The SRS Drawing Office collection of signal box diagrams has been built up over many years and constitutes hand-drawn sketches of the layout controlled by a signal box, with signals and connections numbered.

Enclosure for electrical installations. Electrical installations in a vault, room, closet or in an area surrounded by a wall, screen, or fence, access to which is controlled by lock and key or other equivalent means, are considered to be accessible to qualified persons only.Standard Interpretations: Display all referenced documents. Scroll to Top. .

Electrical continuity of metal raceways and enclosures. Metal raceways, cable armor, and other metal enclosures for conductors shall be metallically joined together into a continuous electric .Enclosure for electrical installations. Electrical installations in a vault, room, closet or in an area surrounded by a wall, screen, or fence, access to which is controlled by lock and key or other equivalent means, are considered to be accessible to qualified persons only.

Electrical continuity of metal raceways and enclosures. Metal raceways, cable armor, and other metal enclosures for conductors shall be metallically joined together into a continuous electric conductor and shall be so connected to all boxes, fittings, and cabinets as to provide effective electrical continuity.Sections 1910.302 through 1910.308 contain design safety standards for electric utilization systems. Included in this category are all electric equipment and installations used to provide electric power and light for employee workplaces.

The space equal to the width and depth of the equipment and extending from the floor to a height of 1.83 m (6.0 ft) above the equipment or to the structural ceiling, whichever is lower, shall be dedicated to the electrical installation. What is the standard for fixing height of MCCB with rotary handle, on the electrical control cabinet

Explore the essential guide to Electrical Enclosure Standards. Understand NEMA, IP ratings, and compliance for safe, efficient electrical installations.

Here’s a side-by-side look at the environmental NEMA enclosure ratings between the National Electrical Manufacturers Association (NEMA) and Underwriters Laboratories, Inc. (UL) (cUL in Canada), CSA Group (CSA), for electrical enclosure types in Class I/Div II . The NEMA regulation that governs electrical enclosure ratings is known as the NEMA 250 Standard. This standard establishes common terminology for performance specifications by outlining 20 distinct NEMA type ratings.This publication, FPL's Electric Service Standards (ESS), is intended to furnish information often required by customers and their agents (builders, architects, engineers, electricians, etc.) to receive FPL's electricThis discussion covers requirements in OSHA’s Design Safety Standards for Electrical Systems that are frequently overlooked and may present serious hazards. The reader is encouraged to consult the complete text of OSHA’s electrical standards for all of OSHA’s requirements.

Enclosure for electrical installations. Electrical installations in a vault, room, closet or in an area surrounded by a wall, screen, or fence, access to which is controlled by lock and key or other equivalent means, are considered to be accessible to qualified persons only.

cnc machining process reading

working space for electrical equipment

Electrical continuity of metal raceways and enclosures. Metal raceways, cable armor, and other metal enclosures for conductors shall be metallically joined together into a continuous electric conductor and shall be so connected to all boxes, fittings, and cabinets as to provide effective electrical continuity.Sections 1910.302 through 1910.308 contain design safety standards for electric utilization systems. Included in this category are all electric equipment and installations used to provide electric power and light for employee workplaces.

The space equal to the width and depth of the equipment and extending from the floor to a height of 1.83 m (6.0 ft) above the equipment or to the structural ceiling, whichever is lower, shall be dedicated to the electrical installation. What is the standard for fixing height of MCCB with rotary handle, on the electrical control cabinet Explore the essential guide to Electrical Enclosure Standards. Understand NEMA, IP ratings, and compliance for safe, efficient electrical installations.

Here’s a side-by-side look at the environmental NEMA enclosure ratings between the National Electrical Manufacturers Association (NEMA) and Underwriters Laboratories, Inc. (UL) (cUL in Canada), CSA Group (CSA), for electrical enclosure types in Class I/Div II .

The NEMA regulation that governs electrical enclosure ratings is known as the NEMA 250 Standard. This standard establishes common terminology for performance specifications by outlining 20 distinct NEMA type ratings.This publication, FPL's Electric Service Standards (ESS), is intended to furnish information often required by customers and their agents (builders, architects, engineers, electricians, etc.) to receive FPL's electric

osha unguarded parts elevation requirements

cnc machining prototypes

Material: Stainless steel, plastic | Size: 24 oz. 32 oz. 40 oz. | Sipping system: Straw and wide-mouth opening The Owala FreeSip checks a lot of boxes when it comes to a quality, user-friendly water bottle. With two drinking options — a wide-mouth opening and a built-in straw — plus an insulated stainless steel container, this bottle keeps your drink cold and your .

electrical enclosures elevation standard|osha unguarded parts elevation requirements