make sheet metal part solidworks You can design a sheet metal part on its own without any references to the parts . X-Carve (First Generation) Plus Workstation. Surrey, UK. £1k. OHIO Fully Upgraded Xcarve, 1/4" Aluminum Bed, FEIN 1 Vac, Complete Workbench/Cabinets and .

0 · solidworks sheet metal template

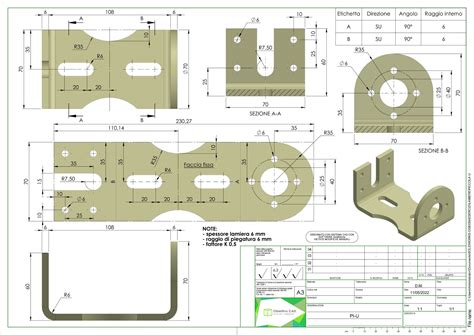

1 · solidworks sheet metal pdf

2 · solidworks sheet metal part drawing

3 · solidworks sheet metal drawing pdf

4 · solidworks sheet metal download

5 · solidworks sheet metal basics

6 · sheet metal drawing in solidworks

7 · sheet metal 3d sketch solidworks

The Xiaomi Square Box 2 is a Bluetooth speaker that ticks both of these boxes. With a battery that lasts more than 6 hours and a portable lightweight body, is this the best Bluetooth speaker? Nope, not even close, but considering it’s price, you will not regret it.The speaker comes in a small, white box, which isn't unusual from Xiaomi An image of the speaker is printed on the front, while the specs can be seen on the back. According to the specs, the speaker sports Bluetooth 4.2 which has a range of 10 meters, battery life should be about 10 hours and the speaker . See more

solidworks sheet metal template

The Convert to Sheet Metal command lets you specify the thickness, bends, and rips necessary to convert a solid part to a sheet metal part.You can design a sheet metal part on its own without any references to the parts .To create a sheet metal part from the flattened state: Open a new part. Create .

You can design a sheet metal part on its own without any references to the parts it will enclose, you can design the part in the context of an assembly that contains the enclosed components, . By converting a solid part to sheet metal within SOLIDWORKS, you can simulate these fabrication processes, ensuring the part can be .

metal mesh large storage box

To create a sheet metal part from the flattened state: Open a new part. Create a sketch as shown. You do not have to dimension the part. Create a Base-Flange by clicking Base-Flange/Tab or . SOLIDWORKS 3D allows you to quickly create sheet metal part designs using a simple design process, saving you time and development costs, thanks to specific sheet metal features. We can use these features to create .

By the end of this tutorial, you'll be well-equipped to design your own sheet metal components confidently in SolidWorks. Music: Inspire by Wavecont https://protunes.net Video Link: •. In this lesson, you create the sheet metal part. This lesson demonstrates: 1.Creating a base flange 2.Adding a miter flange 3.Mirroring the part and creating. How to Use SolidWorks Base Flange | SolidWorks SheetMetal Tutorial #1. Base Flange is first and basic step used to start sheet metal model. It is applicable one per part file. You can create single open, single closed or .

Sheet metal parts are made with a constant thickness. They start out as one flat sheet and then are cut and bent to make the final product. When it comes to creating a sheet metal part in SOLIDWORKS you have two choices .Click Insert Bends (Sheet Metal toolbar) or Insert > Sheet Metal > Bends.; In the PropertyManager, under Bend Parameters:. Click a face or edge on the model for Fixed Face or Edge.The fixed face remains in place when the part is flattened. Set a value for Bend Radius.; Under Bend Allowance, select from: Bend Table, K-Factor, Bend Allowance, Bend Deduction, .If you are just trying to make the curved section a piece of sheet metal then select a parallel plane to the two flats. Convert a line from one of the flat parts on the side you want the bent piece to be on. Make sure there is some small part of .This cannot directly make a conic bend though. You may be better off measuring the length of what will become the circular top and circular bottom of the cone from the flat pattern then use that to construct the cone directly as a 3D sheet metal piece to flatten (like this: GoEngineer - SOLIDWORKS: Sheet Metal Cone).

By using the Base Flange/Tab, create a circle with a small gap in it. That gap is for the cut on the sheet to make it possible to roll in a cylinder form. After that you just add your thickness and bend radius. If you can use your flatten view then you know the sheet has a correct bend in it. Checkout our free inar for SolidWorks Beginners

There are multiple methods for making sheet metal parts in Solidworks using the Sheet Metal tab. In this article, . To make a sheet metal part entirely using the Sheet Metal tab, we need to start with a flange. We can use a closed sketch to make a flat flange, or we can use an open sketch to make the profile of a flange with the bends already . How to Start a Sheet Metal Part in SolidWorksLET'S CONNECT!Google+ https://plus.google.com/+Cati1/posts Facebook https://www.facebook.com/CatiSolidWorks T.Now create a drawing of the sheet metal part. Start with an isometric view of the folded model, and then add a view of the unfolded model. Click Options (Standard toolbar).; On the System Options tab, click Drawings > Display Style.; Under Tangent edges, select Visible, and click OK.; Click Make Drawing from Part/Assembly (Standard toolbar) or File > Make Drawing from Part, .When adding a cut to a folded sheet metal part, select Normal cut to ensure that the cut is created normal to the sheet metal thickness. Creating Sheet Metal Parts with Cylindrical Faces. Adding Walls to Sheet Metal Parts. Creating Elliptical Bends. You can sketch an ellipse and a create sheet metal part that has elliptical bends. Drawings of .

When adding a cut to a folded sheet metal part, select Normal cut to ensure that the cut is created normal to the sheet metal thickness. Creating Sheet Metal Parts with Cylindrical Faces. Adding Walls to Sheet Metal Parts. Creating Elliptical Bends. You can sketch an ellipse and a create sheet metal part that has elliptical bends. Drawings of .You can create a multibody sheet metal part from multiple sheet metal bodies or a combination of sheet metal bodies and and other bodies such as weldments. . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. Use the form below to send your comments and suggestions about this topic .The sheet metal-specific features make it easier and faster to create a sheet metal part than designing a part, then converting it to sheet metal. SOLIDWORKS includes sheet metal-specific features so you can create a part as sheet metal without having to convert it to sheet metal.

If you cannot insert an axis, then the model is not an exact cylinder and cannot be unfolded. However, sheet metal parts created with the Lofted Bends feature avoid this limitation and unfold appropriately. . Version: SOLIDWORKS 2018 SP05 To disable help from within SOLIDWORKS and use local help instead, click Help > Use SOLIDWORKS .If creating a sheet metal part with one or more conical faces, you must select K-Factor as the type of bend allowance. If you selected K-Factor, Bend Allowance, . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. Use the form below to send your comments and suggestions about this .

solidworks sheet metal pdf

solidworks sheet metal part drawing

When you create a drawing of your sheet metal part, a flat pattern is automatically created. Drawings of sheet metal parts can also contain views of the bent sheet metal part. . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. Use the form below to send your comments and .

When adding a cut to a folded sheet metal part, select Normal cut to ensure that the cut is created normal to the sheet metal thickness. Creating Sheet Metal Parts with Cylindrical Faces. Adding Walls to Sheet Metal Parts. Creating Elliptical Bends. You can sketch an ellipse and a create sheet metal part that has elliptical bends. Drawings of .Click Insert Bends (Sheet Metal toolbar) or Insert > Sheet Metal > Bends.; In the PropertyManager, under Bend Parameters:. Click a face or edge on the model for Fixed Face or Edge.The fixed face remains in place when the part is flattened. .76K subscribers in the SolidWorks community. ALL posts related to SOLIDWORKS are welcome. . Is there is a way to change the thickness of a sheet metal without modifying the dimensions of the part? Share Add a .Hi u/Jadas922, . You are in "Flat Pattern" mode for sheet metal. Creating sheet metal features is not appropriate in that mode so they are grayed out. Clicking the button in the top right of the viewport will bring you back out of this to the folded state of the model.

When you mirror features and bodies in a sheet metal part, many of the bends are mirrored as well. The only bends that are not mirrored are those that are normal to and coincident to the mirror plane; those bends are extended. . Search 'Mirroring Sheet Metal Parts' in the SOLIDWORKS Knowledge Base. Provide feedback on this topic. SOLIDWORKS .You can create a multibody sheet metal part using any command that creates multiple bodies from a single body. Use these commands on the Features toolbar to split a sheet metal part into multiple bodies: . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. .

I am trying to make this simplified dog from sheet metal, https://ibb.co/XC0KJDj but I don't get the order to make the head part correctly. Now I am stuck at this position, I don't know how to attach the side parts to head parts, because of their shape . In the base flange section, you seen the very first step to make sheet metal design in SolidWorks CAD software. The Edge Flange feature helps to add flanges to selected edge or more edges. . For showing SolidWorks Edge flange application, we are going to create new base flange sheet metal part. You can follow step 1 and step 2 and result is .

When you create a drawing of your sheet metal part, a flat pattern is automatically created. Drawings of sheet metal parts can also contain views of the bent sheet metal part. . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. Use the form below to send your comments and .It is possible to create a solid part, then convert it to sheet metal to add the bends and sheet metal features. . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. Use the form below to send your comments and suggestions about this topic directly to our documentation team.

When adding a cut to a folded sheet metal part, select Normal cut to ensure that the cut is created normal to the sheet metal thickness. Creating Sheet Metal Parts with Cylindrical Faces. Adding Walls to Sheet Metal Parts. Creating Elliptical Bends. You can sketch an ellipse and a create sheet metal part that has elliptical bends. Drawings of .When adding a cut to a folded sheet metal part, select Normal cut to ensure that the cut is created normal to the sheet metal thickness. Creating Sheet Metal Parts with Cylindrical Faces. Adding Walls to Sheet Metal Parts. Creating Elliptical Bends. You can sketch an ellipse and a create sheet metal part that has elliptical bends. Drawings of .

How to Prepare Rolled Sheet Metal Parts in SolidWorks. Let’s walk through the steps necessary to flatten a rolled sheet metal part in Solidworks to prepare it for laser cutting. Step 1: Use “Cut-Extrude” to make a parting line in your rolled part. First, open your transition part file and make a parting line which will be the seam when .

metal mesh sheets home depot

ORIGINAL WW2 GERMAN METAL BOX 8cm Wgr.34 3x 8cm MINES MORTAR GRANATWERFER. Find great deals on eBay for Ww2 Box. Shop with confidence.

make sheet metal part solidworks|solidworks sheet metal pdf