can i use repetier host with a cnc machine Repetier Host Settings for FLSUN Q5. 1 view 1 comment 0 points Most recent by . Pros of Metal Piping. More Fire Resistant: Metal piping is more fire resistant than plastic and can be installed in above-ceiling return-air plenums with no limitations. Easier Pipe Penetration: Pipe penetration of fire rated walls and floors is easier than with plastic pipes. Needs Fewer Supports: Metal pipe is more ridged than plastic and requires fewer hangers and supports.

0 · repetier host cnc

1 · repetier cnc server

Choose screws with a diameter that matches the size of the mounting holes in the electrical box. The length of the screw should be sufficient to penetrate through the box and provide a secure fit without protruding.

repetier host cnc

i use repetier host and firmware and this is realy great. I preprare hybrid machine for 3d print and CNC. Please, is there some solution for work CNC with this firmware?Repetier Host Settings for FLSUN Q5. 1 view 1 comment 0 points Most recent by .I’m not using an LCD, I’m controlling the CNC with Repetier-host. I’ve done some . That would usually be the job of MACH3 and here Repetier Host. The CAM work should be left to a CAM software because things like tool shapes, tool diameters, correct rpm .

I’m not using an LCD, I’m controlling the CNC with Repetier-host. I’ve done some cutting of simple 2d designs using one size bit and everything runs fine through Repetier. But if I want to do .As I knew , Repetier server can control multiple printers simultaneously , but if we build a repetier firmware for CNC , could we control the 3D printer and a C.

china cnc machined component factory

Just wanted to say I today developed a plugin for Repetier Host with focus on CNC machines. It simplifies jogging (with keyboard) and height probing. [ github.com ] Find out more or build your own CNC Machine here:http://www.thingiverse.com/thing:724999Like & Subscribe For More Videos!Buy Cheap Games & Tech Here:http://a.Prusa slicr and associated freeware for the 3d printer, and just recently we started running on a Plasma CNC with sheetCam and repetier host. CAD/CAM gets done in Vectric Aspire, fusion, .Repetier Server on a Raspberry Pi that's connected to the CNC. Then I can use my laptop or old tablet/iPad to control the machine from a browser. Love it!

I used the CNC setting in Repetier and still makes no difference. Is there a setting I can change so that the temps are not required to print? or is there a better program to use for . I use Repetier-Host as my CNC controller program with Marlin_pp as my Post Processor (which is got from the MPCNC Lowrider2 site). Here is the issue: I program my cut, .

i use repetier host and firmware and this is realy great. I preprare hybrid machine for 3d print and CNC. Please, is there some solution for work CNC with this firmware? That would usually be the job of MACH3 and here Repetier Host. The CAM work should be left to a CAM software because things like tool shapes, tool diameters, correct rpm for the spindle, and the difference between roughing, finishing and contour are nothing Skeinforge is even remotely capable of.I’m not using an LCD, I’m controlling the CNC with Repetier-host. I’ve done some cutting of simple 2d designs using one size bit and everything runs fine through Repetier. But if I want to do more complicated carves I need the ability to pause the program and change to a different bit.As I knew , Repetier server can control multiple printers simultaneously , but if we build a repetier firmware for CNC , could we control the 3D printer and a C.

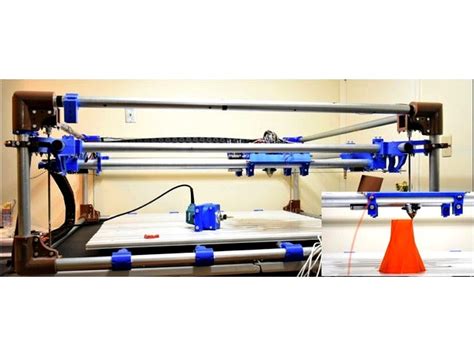

Just wanted to say I today developed a plugin for Repetier Host with focus on CNC machines. It simplifies jogging (with keyboard) and height probing. [ github.com ]

Find out more or build your own CNC Machine here:http://www.thingiverse.com/thing:724999Like & Subscribe For More Videos!Buy Cheap Games & Tech Here:http://a.

Prusa slicr and associated freeware for the 3d printer, and just recently we started running on a Plasma CNC with sheetCam and repetier host. CAD/CAM gets done in Vectric Aspire, fusion, illustrator, inkscape, and so on. Repetier Server on a Raspberry Pi that's connected to the CNC. Then I can use my laptop or old tablet/iPad to control the machine from a browser. Love it! I used the CNC setting in Repetier and still makes no difference. Is there a setting I can change so that the temps are not required to print? or is there a better program to use for a CNC 3D printer machine?

repetier cnc server

I use Repetier-Host as my CNC controller program with Marlin_pp as my Post Processor (which is got from the MPCNC Lowrider2 site). Here is the issue: I program my cut, save it with the marlin_pp send it to my machine.i use repetier host and firmware and this is realy great. I preprare hybrid machine for 3d print and CNC. Please, is there some solution for work CNC with this firmware?

That would usually be the job of MACH3 and here Repetier Host. The CAM work should be left to a CAM software because things like tool shapes, tool diameters, correct rpm for the spindle, and the difference between roughing, finishing and contour are nothing Skeinforge is even remotely capable of.I’m not using an LCD, I’m controlling the CNC with Repetier-host. I’ve done some cutting of simple 2d designs using one size bit and everything runs fine through Repetier. But if I want to do more complicated carves I need the ability to pause the program and change to a different bit.As I knew , Repetier server can control multiple printers simultaneously , but if we build a repetier firmware for CNC , could we control the 3D printer and a C. Just wanted to say I today developed a plugin for Repetier Host with focus on CNC machines. It simplifies jogging (with keyboard) and height probing. [ github.com ]

Find out more or build your own CNC Machine here:http://www.thingiverse.com/thing:724999Like & Subscribe For More Videos!Buy Cheap Games & Tech Here:http://a.Prusa slicr and associated freeware for the 3d printer, and just recently we started running on a Plasma CNC with sheetCam and repetier host. CAD/CAM gets done in Vectric Aspire, fusion, illustrator, inkscape, and so on.

Repetier Server on a Raspberry Pi that's connected to the CNC. Then I can use my laptop or old tablet/iPad to control the machine from a browser. Love it!

I used the CNC setting in Repetier and still makes no difference. Is there a setting I can change so that the temps are not required to print? or is there a better program to use for a CNC 3D printer machine?

Gaming PC chassis are often composed of two metals. These are made of aluminum and steel. Let’s talk about which material is ideal for your gaming PC case. Does a PC Need a Metal Case? I will compare aluminum and steel frames in this article.

can i use repetier host with a cnc machine|repetier host cnc