cnc machine programmer and operator CNC Machinists are the hands-on operators who bring the machining programs to life, while CNC Programmers are the technical experts who create and optimize these . Consider upgrading your electrical panel for a budget-friendly fix that slashes energy bills and boosts safety and efficiency. This proactive step .

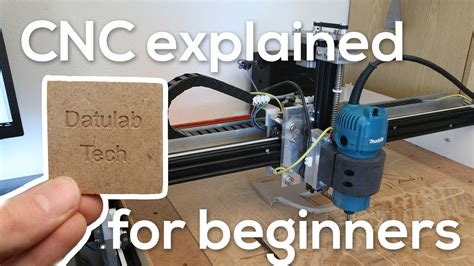

0 · programming cnc for beginners

1 · introduction to cnc programming

2 · difference between machinist and operator

3 · cnc programming full form

4 · cnc programming courses near me

5 · cnc programmer vs machinist

6 · cnc programmer and machinist

7 · basics of cnc programming

$171.59

The operator maintains and oversees the machine, while CNC machinists oversee system operations and the operators who load materials and aim the instruments. CNC .

kiss metal lunch box

CNC operators set up and operate CNC machines and equipment. On any given day, an operator may unload raw materials, prepare a test run to ensure a machine is working properly and inspect and measure finished products to . CNC operators, machinists and programmers are essential for implementing, operating and maintaining CNC machining processes. Learning about the similarities and . CNC Machinists are the hands-on operators who bring the machining programs to life, while CNC Programmers are the technical experts who create and optimize these .

Machine Operation: Operators are responsible for setting up and operating the CNC machine. They start, stop, and control the machine during its operation. Loading and Unloading: They load raw materials into the machine . CNC Machinist vs. Operator vs. Programmer While there's overlap in the roles, a CNC operator typically focuses on running the machine and ensuring basic quality, while a CNC machinist has a deeper knowledge of the . CNC operators focus on basic machine operation, while machinists perform advanced tasks using CAD/CAM software. Operators typically require a high school diploma, whereas machinists benefit from technical education in .

CNC Machinist vs. CNC Programmer. The basics of CNC machining start with the CNC programmer. Afterall, this is the person who develops the programs and instructions needed to operate CNC equipment! This professional may also set up, operate, or maintain equipment.

The operator maintains and oversees the machine, while CNC machinists oversee system operations and the operators who load materials and aim the instruments. CNC programmers instruct the mechanists what to do each day, .

CNC operators set up and operate CNC machines and equipment. On any given day, an operator may unload raw materials, prepare a test run to ensure a machine is working properly and inspect and measure finished products to ensure they meet requirements.

CNC operators, machinists and programmers are essential for implementing, operating and maintaining CNC machining processes. Learning about the similarities and differences between these roles helps you determine . CNC Machinists are the hands-on operators who bring the machining programs to life, while CNC Programmers are the technical experts who create and optimize these programs. Their collaboration and continuous interaction are vital for ensuring high-quality production and operational efficiency. Machine Operation: Operators are responsible for setting up and operating the CNC machine. They start, stop, and control the machine during its operation. Loading and Unloading: They load raw materials into the machine and unload finished parts once the machining process is complete.

CNC Machinist vs. Operator vs. Programmer While there's overlap in the roles, a CNC operator typically focuses on running the machine and ensuring basic quality, while a CNC machinist has a deeper knowledge of the entire process, including programming, complex troubleshooting, and process optimization. CNC operators focus on basic machine operation, while machinists perform advanced tasks using CAD/CAM software. Operators typically require a high school diploma, whereas machinists benefit from technical education in machining and programming.

A CNC Programmer is responsible for creating the instructions that control CNC machines. CNC Programmers translate design specifications and blueprints into machine-readable code that allows a machine to produce accurate and consistent products.To summarize, working as a CNC operator or a CNC programmer has its own pros and cons. A CNC operator has less education and training requirements, but also less career and salary. CNC Machinist vs. CNC Programmer. The basics of CNC machining start with the CNC programmer. Afterall, this is the person who develops the programs and instructions needed to operate CNC equipment! This professional may also set up, operate, or maintain equipment. The operator maintains and oversees the machine, while CNC machinists oversee system operations and the operators who load materials and aim the instruments. CNC programmers instruct the mechanists what to do each day, .

CNC operators set up and operate CNC machines and equipment. On any given day, an operator may unload raw materials, prepare a test run to ensure a machine is working properly and inspect and measure finished products to ensure they meet requirements.

CNC operators, machinists and programmers are essential for implementing, operating and maintaining CNC machining processes. Learning about the similarities and differences between these roles helps you determine .

programming cnc for beginners

CNC Machinists are the hands-on operators who bring the machining programs to life, while CNC Programmers are the technical experts who create and optimize these programs. Their collaboration and continuous interaction are vital for ensuring high-quality production and operational efficiency. Machine Operation: Operators are responsible for setting up and operating the CNC machine. They start, stop, and control the machine during its operation. Loading and Unloading: They load raw materials into the machine and unload finished parts once the machining process is complete. CNC Machinist vs. Operator vs. Programmer While there's overlap in the roles, a CNC operator typically focuses on running the machine and ensuring basic quality, while a CNC machinist has a deeper knowledge of the entire process, including programming, complex troubleshooting, and process optimization.

CNC operators focus on basic machine operation, while machinists perform advanced tasks using CAD/CAM software. Operators typically require a high school diploma, whereas machinists benefit from technical education in machining and programming. A CNC Programmer is responsible for creating the instructions that control CNC machines. CNC Programmers translate design specifications and blueprints into machine-readable code that allows a machine to produce accurate and consistent products.

introduction to cnc programming

A: Magnetic steel, such as galvanized steel, can be attracted to a magnet, while non-magnetic steel, like austenitic stainless steel, does not exhibit magnetic properties. Q: Can galvanized steel be cut to size without losing its magnetic properties?Magnets will not stick to nonmetal materials — like plastic, wood, cloth, paper, and fiberglass — which you may know from experience. That's because these materials have low permeability — magnetization generated from an applied .

cnc machine programmer and operator|cnc programming courses near me