cnc machine programmers CNC programming refers to the process of creating instructions or code that is used to control computer numerical control (CNC) machines. CNC machines are automated manufacturing tools that perform precise and complex operations on various materials, such . 16-Gauge stainless steel: premium 16-gauge thickness and type 304 stainless steel for immense durability, performance and lustrous beauty. Quiet: sound-deadening materials minimize sound and vibration for a quieter time at the sink

0 · different types of cnc programming

1 · cnc programming website

2 · cnc programming software free download

3 · cnc programming full form

4 · cnc programming for beginners

5 · cnc machine tool programming

6 · cnc machine programming and operation

7 · basic cnc programming for freshers

Over 75 years experience in machining quality CNC turned parts for Automotive, Aerospace, Defence, Hydraulic, Lighting, Medical, Safety, Switchgear, Transport, Telecoms and Leisure markets. Three state of the art UK machining facilities .

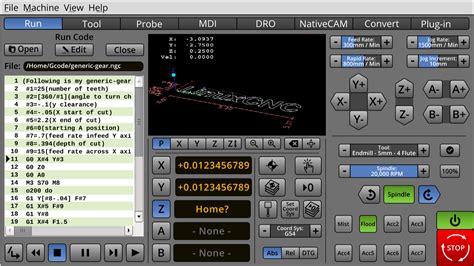

CNC programming refers to the process of creating instructions or code that is used to control computer numerical control (CNC) machines. CNC machines are automated manufacturing . CNC programming (Computer Numerical Control programming) is creating instructions for a CNC machine using software to control how it moves and interacts with the material workpiece. These machines include CNC milling machines, CNC lathes , and 3D printers.

CNC programming refers to the process of creating instructions or code that is used to control computer numerical control (CNC) machines. CNC machines are automated manufacturing tools that perform precise and complex operations on various materials, such . CNC programming is the process of converting a 3D model into machine-readable instructions in order to perform automated machining operations. Learn more about it here. Plus, learn how it’s used and all the important codes

With a keen eye for detail, CNC machine programmers meticulously consider factors like tool selection, cutting paths, and machining sequences to optimize production efficiency and ensure accuracy. Beyond programming, they continuously monitor and troubleshoot machine operations, adjusting parameters to maintain quality standards.1,136 CNC Programmer jobs available on Indeed.com. Apply to CNC Programmer, CNC Machinist, Metal Fabricator and more!

A CNC programmer is responsible for writing the code that tells CNC machines how to operate. They develop programs that define the cutting paths, speeds, and tool movements required to create parts or products based on technical drawings or 3D models. CNC programmers use Computer Aided Manufacturing (CAM) software to work with 3D models of parts. They then create tool paths, or instructions in the form of code, to direct machinery and create those parts.

In basic terms, CNC programming is the process used to create program instructions for computers to control a CNC machine and tooling. CNC machines turn a digital file into a sequence of computer instructions, which are then sent to a motorized tool such as a mill, router, grinder or lathe.

Career Spotlight: How Do I Become a CNC Programmer? The role of CNC programmer is central to most modern machine shops. Read on to discover the job responsibilities, training and education required to enter this field and create a .CNC machine programming offers a systematic approach to controlling automated equipment with precision and efficiency. It involves converting design concepts into a language that computer-controlled machinery, such as mills, lathes, or routers, understands. CNC programming (Computer Numerical Control programming) is creating instructions for a CNC machine using software to control how it moves and interacts with the material workpiece. These machines include CNC milling machines, CNC lathes , and 3D printers.CNC programming refers to the process of creating instructions or code that is used to control computer numerical control (CNC) machines. CNC machines are automated manufacturing tools that perform precise and complex operations on various materials, such .

CNC programming is the process of converting a 3D model into machine-readable instructions in order to perform automated machining operations. Learn more about it here. Plus, learn how it’s used and all the important codes

https goldenopenings.com giant-metal-house-realtor-key _p_833.html

different types of cnc programming

With a keen eye for detail, CNC machine programmers meticulously consider factors like tool selection, cutting paths, and machining sequences to optimize production efficiency and ensure accuracy. Beyond programming, they continuously monitor and troubleshoot machine operations, adjusting parameters to maintain quality standards.1,136 CNC Programmer jobs available on Indeed.com. Apply to CNC Programmer, CNC Machinist, Metal Fabricator and more!

A CNC programmer is responsible for writing the code that tells CNC machines how to operate. They develop programs that define the cutting paths, speeds, and tool movements required to create parts or products based on technical drawings or 3D models. CNC programmers use Computer Aided Manufacturing (CAM) software to work with 3D models of parts. They then create tool paths, or instructions in the form of code, to direct machinery and create those parts. In basic terms, CNC programming is the process used to create program instructions for computers to control a CNC machine and tooling. CNC machines turn a digital file into a sequence of computer instructions, which are then sent to a motorized tool such as a mill, router, grinder or lathe.

Career Spotlight: How Do I Become a CNC Programmer? The role of CNC programmer is central to most modern machine shops. Read on to discover the job responsibilities, training and education required to enter this field and create a .

cnc programming website

hs code sheet metal parts

The National Electric Code (NEC) specifies a minimum size for pull, junction box and conduit bodies. The code specifies this based on whether it is a straight pull or the conductor turns in an angle or u pull. The code treats a splice internal to the box the same as an angle or u-pull.Our underground pull boxes are strong and durable, with the broadest and most complete line offered in the industry. We offer an extensive selection of plastic, concrete, polymer concrete, and composite underground pull boxes and handholes in variety of sizes.

cnc machine programmers|cnc programming for beginners