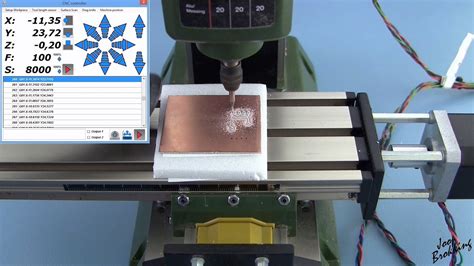

cnc machine pcb making Learn the art of making high-quality PCBs using a CNC milling machi. Experience the fascinating world of PCB manufacturing with this step-by-step video guide.

The most commonly-used sheet metal sizes range from 26 gauge (thinner) to 7 gauge (thicker). A sheet metal gauge tool is used to measure metal thickness and shows both the gauge number as well as the thickness of the metal in thousandths of an inch.

0 · pcb milling machine for hobbyist

1 · making pcb with cnc router

2 · cnc pcb milling machine

3 · cnc pcb mill milling cutter

4 · cnc pcb engraving bits

5 · cnc machine for pcb fabrication

6 · cheapest pcb milling machine

7 · best cnc for pcb milling

If you're caught stopping inappropriately, then you'll could receive a fine ranging from £70 to £130 depending on the junction — but the fine is halved if it is paid within 14 days of being.

This section helps you calculate your cut depth if you are using a V bit. As I said earlier, I find it easier to choose the "C1" bit type and put in the depth myself. Thus if you are following my path, you can simply ignore this section. See moreClick "Generate CNC object" Now you have a "simulated" CNC plot and an option to save it (third image). Here is a quick look at what was saved: Check out the LOOK HERE section above. My particular machine does not like the T1 (tool change) code, your's may be . See more If you ever wanted to make PCBs of your own, and if you have access to a milling machine, then this tutorial will cover all the basics. This is a .In this comprehensive guide, we will walk you through every step of the process, from concept to creation, enabling you to harness the power of CNC machines and create your own PCB .

Make Your Own PCBs on an Inexpensive Desktop CNC Mill: Traditionally, there are two ways of hobbyists making custom PCBs: 1. Using toner transfer and .

Learn the art of making high-quality PCBs using a CNC milling machi. Experience the fascinating world of PCB manufacturing with this step-by-step video guide.One of the key tools in the PCB making process is a CNC (Computer Numerical Control) machine. In this comprehensive guide, we will take a deep dive into the world of PCB making . But in reality, PCB manufacturing CNC machines is your go-to solution for efficiently manufacturing printed circuit boards (PCBs). These CNC manufacturing systems .

By creating an easy path from a digital PCB design to a physical, testable board, milling machines are the quickest way to get your designs ready for production.

Drill, Mill, Cut: There are three processes for creating a PCB. First vias (holes for components) are drilled. Second, the clearances for the traces are milled. Finally, the board is cut to shape. Tooling: Each process should use .PCB milling is a precise method in circuit board manufacturing, using CNC machines to remove copper from substrates. It offers flexibility for custom designs, making it ideal for prototypes and small batches, reducing time .Milling Printed Circuit Boards (PCBs) on a Cheap CNC Machine: This guide presents an entire end-to-end process of milling PCBs with a "cheap" 3018 CNC machine (although other CNC machine types can also be used). If you ever wanted to make PCBs of your own, and if you have access to a milling machine, then this tutorial will cover all the basics. This is a really simple and short tutorial that will help you start making PCBs using the Roland PCB milling machine (Roland Modela MDX-20).

In this comprehensive guide, we will walk you through every step of the process, from concept to creation, enabling you to harness the power of CNC machines and create your own PCB designs with confidence.Make Your Own PCBs on an Inexpensive Desktop CNC Mill: Traditionally, there are two ways of hobbyists making custom PCBs: 1. Using toner transfer and chemical etchant -- can be tricky to get the right materials, and the chemicals are nasty and messy 2. Paying a service like BatchPCB or OshPark -- fairly.Learn the art of making high-quality PCBs using a CNC milling machi. Experience the fascinating world of PCB manufacturing with this step-by-step video guide.One of the key tools in the PCB making process is a CNC (Computer Numerical Control) machine. In this comprehensive guide, we will take a deep dive into the world of PCB making CNC machines, their importance, working principle, and how to use them effectively for the production of high-quality PCBs.

But in reality, PCB manufacturing CNC machines is your go-to solution for efficiently manufacturing printed circuit boards (PCBs). These CNC manufacturing systems allow you to create precise circuit patterns and holes using automated processes like .

pcb milling machine for hobbyist

making pcb with cnc router

By creating an easy path from a digital PCB design to a physical, testable board, milling machines are the quickest way to get your designs ready for production.

Drill, Mill, Cut: There are three processes for creating a PCB. First vias (holes for components) are drilled. Second, the clearances for the traces are milled. Finally, the board is cut to shape. Tooling: Each process should use the appropriate tools.

PCB milling is a precise method in circuit board manufacturing, using CNC machines to remove copper from substrates. It offers flexibility for custom designs, making it ideal for prototypes and small batches, reducing time constraints.

Milling Printed Circuit Boards (PCBs) on a Cheap CNC Machine: This guide presents an entire end-to-end process of milling PCBs with a "cheap" 3018 CNC machine (although other CNC machine types can also be used).

If you ever wanted to make PCBs of your own, and if you have access to a milling machine, then this tutorial will cover all the basics. This is a really simple and short tutorial that will help you start making PCBs using the Roland PCB milling machine (Roland Modela MDX-20).In this comprehensive guide, we will walk you through every step of the process, from concept to creation, enabling you to harness the power of CNC machines and create your own PCB designs with confidence.Make Your Own PCBs on an Inexpensive Desktop CNC Mill: Traditionally, there are two ways of hobbyists making custom PCBs: 1. Using toner transfer and chemical etchant -- can be tricky to get the right materials, and the chemicals are nasty and messy 2. Paying a service like BatchPCB or OshPark -- fairly.Learn the art of making high-quality PCBs using a CNC milling machi. Experience the fascinating world of PCB manufacturing with this step-by-step video guide.

One of the key tools in the PCB making process is a CNC (Computer Numerical Control) machine. In this comprehensive guide, we will take a deep dive into the world of PCB making CNC machines, their importance, working principle, and how to use them effectively for the production of high-quality PCBs. But in reality, PCB manufacturing CNC machines is your go-to solution for efficiently manufacturing printed circuit boards (PCBs). These CNC manufacturing systems allow you to create precise circuit patterns and holes using automated processes like .

By creating an easy path from a digital PCB design to a physical, testable board, milling machines are the quickest way to get your designs ready for production. Drill, Mill, Cut: There are three processes for creating a PCB. First vias (holes for components) are drilled. Second, the clearances for the traces are milled. Finally, the board is cut to shape. Tooling: Each process should use the appropriate tools.

cnc pcb milling machine

cnc pcb mill milling cutter

The major difference between a junction box and a utility box is that a junction box would house the electrical connections while the utility boxes are used to install switches, fixtures, etc. Some useful information about Junction boxes

cnc machine pcb making|pcb milling machine for hobbyist