broaching cnc machining Broaching is a machining process that uses a toothed tool to remove material in a consistent and accurate way. There are two types of . Install wire mesh, galvanized metal, or slatted shelves along the sides, leaving enough space for easy access and airflow. Consider a multi-tiered shelving system to maximize your vertical space.

0 · what is broaching cnc machining

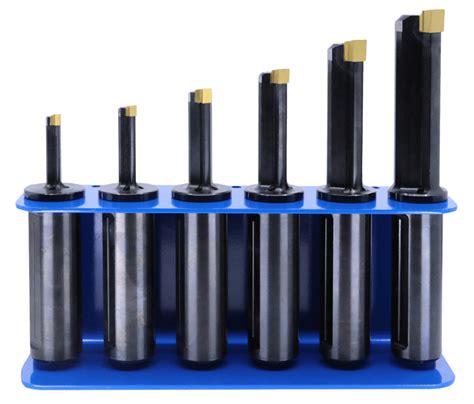

1 · cnc broaching tool company

2 · cnc broaching tool

3 · cnc broaching process

4 · broaching tool for cnc mill

5 · broaching tool for cnc lathe

6 · broaching on cnc lathe

7 · broaching on a cnc mill

$589.00

Broaching is an unusual machining process, because it has the feed built into the tool, which effectively makes it a collection of single-point . Broaching in CNC Machining is a immensely useful and fast tactic to creating unique shapes on parts! Walk through Rotary Broaching as Donnie explains how it . Broaching is a machining process that uses a toothed tool to remove material in a consistent and accurate way. There are two types of .Broaching is a machining process that uses a toothed tool, called a broach, to remove material. There are two main types of broaching: linear and rotary. In linear broaching, which is the more common process, the broach is run linearly against a surface of the workpiece to produce the cut. Linear broaches are used in a broaching machine, which is also sometimes shortened to broach. In rota.

what is broaching cnc machining

cnc broaching tool company

Broaching is a machining process that involves removing material using a special tool called a broach. The broach is a multi-toothed cutting tool that progressively increases in size, enabling it to cut different parts of a workpiece . Keyway broaching (keyway slotting, key slotting) is an essential machining process used to create internal slots or keyways in a workpiece, such as a gear. These keyways enable the transmission of torque between the . The benefits of broaching on a CNC machine include fast speeds to create final forms, high accuracy, low heat, high repeatability and easy operation utilizing standard drilling G code. Broaching on a CNC machine also .

Making accurate and complex cuts easy and economical for high-volume parts. A broach is a cutting tool with many rows of teeth, each slightly larger than its predecessor. They are designed to produce simple or complex .

Writing a CNC program for broaching internal involute splines can be a complex task, but it can be made easier by understanding some key concepts and techniques. Broaching (Slotting) is a machining process in which a keyway or a profile is created by cutting movements on the Z-axis. The cutting depth is determined with movements of the X-axis. With the working stroke on the Z-axis, material is . Broaching is an unusual machining process, because it has the feed built into the tool, which effectively makes it a collection of single-point cutting tools arrayed in a sequence.

1988 kawasaki jet ski 550 electrical box

cnc broaching tool

1993 volvo 240 junction box wiring diagram

Broaching in CNC Machining is a immensely useful and fast tactic to creating unique shapes on parts! Walk through Rotary Broaching as Donnie explains how it . Broaching is a machining process that uses a toothed tool to remove material in a consistent and accurate way. There are two types of broaching services, linear and rotary, which are used to produce different kinds of machining finishes, but in either case, production broaching is typically only used for precision applications and high-quantity .Broaching is a machining process that uses a toothed tool, called a broach, to remove material. There are two main types of broaching: linear and rotary. In linear broaching, which is the more common process, the broach is run linearly against a surface of the workpiece to produce the cut. Broaching is a machining process that involves removing material using a special tool called a broach. The broach is a multi-toothed cutting tool that progressively increases in size, enabling it to cut different parts of a workpiece in a single pass.

Keyway broaching (keyway slotting, key slotting) is an essential machining process used to create internal slots or keyways in a workpiece, such as a gear. These keyways enable the transmission of torque between the workpiece and a coupling component, such as a shaft.

The benefits of broaching on a CNC machine include fast speeds to create final forms, high accuracy, low heat, high repeatability and easy operation utilizing standard drilling G code. Broaching on a CNC machine also eliminates the need for secondary operations, such as wire EDMing, Derbin said. Making accurate and complex cuts easy and economical for high-volume parts. A broach is a cutting tool with many rows of teeth, each slightly larger than its predecessor. They are designed to produce simple or complex forms quickly, usually in one pass, with repeatable and reliable accuracy. Writing a CNC program for broaching internal involute splines can be a complex task, but it can be made easier by understanding some key concepts and techniques.

Broaching (Slotting) is a machining process in which a keyway or a profile is created by cutting movements on the Z-axis. The cutting depth is determined with movements of the X-axis. With the working stroke on the Z-axis, material is . Broaching is an unusual machining process, because it has the feed built into the tool, which effectively makes it a collection of single-point cutting tools arrayed in a sequence.Broaching in CNC Machining is a immensely useful and fast tactic to creating unique shapes on parts! Walk through Rotary Broaching as Donnie explains how it .

cnc broaching process

Broaching is a machining process that uses a toothed tool to remove material in a consistent and accurate way. There are two types of broaching services, linear and rotary, which are used to produce different kinds of machining finishes, but in either case, production broaching is typically only used for precision applications and high-quantity .

Broaching is a machining process that uses a toothed tool, called a broach, to remove material. There are two main types of broaching: linear and rotary. In linear broaching, which is the more common process, the broach is run linearly against a surface of the workpiece to produce the cut.

Broaching is a machining process that involves removing material using a special tool called a broach. The broach is a multi-toothed cutting tool that progressively increases in size, enabling it to cut different parts of a workpiece in a single pass.

Keyway broaching (keyway slotting, key slotting) is an essential machining process used to create internal slots or keyways in a workpiece, such as a gear. These keyways enable the transmission of torque between the workpiece and a coupling component, such as a shaft. The benefits of broaching on a CNC machine include fast speeds to create final forms, high accuracy, low heat, high repeatability and easy operation utilizing standard drilling G code. Broaching on a CNC machine also eliminates the need for secondary operations, such as wire EDMing, Derbin said. Making accurate and complex cuts easy and economical for high-volume parts. A broach is a cutting tool with many rows of teeth, each slightly larger than its predecessor. They are designed to produce simple or complex forms quickly, usually in one pass, with repeatable and reliable accuracy.

1993 ford f250 power distribution box pinout

You can use plastic covers on metal boxes. Metal covers require that you use a proper method to ground them as well. Typically being screwed to a grounded metal box or a grounded device (receptacle/switch) suffices.

broaching cnc machining|broaching on a cnc mill