automation sheet metal laser cutting Fiber laser cutting technology, employing a high-density energy beam for non-contact rapid cutting, has emerged as a revolutionary solution. It offers fast cutting speeds and micron-level precision, with minimal heat-affected zones, thereby reducing material deformation and thermal stress. If the roof on your home or business has been damaged because of a storm or other mishap, Tri-County Roofing & Sheet Metal will be there to provide emergency roofing services and repair your roof system 24 hours a day, seven days a week.

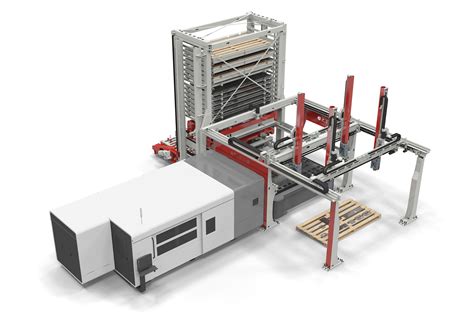

0 · Sheet Metal Laser Cutting Automation Solution

1 · Automatic Sheet Metal Loaders – Automation for Laser Cutting

2 · ASTES4

Structural hollow sections in grades S235, S355 & S420 amongst others. Discover how Barrett Steel's tubes services can help you. Barrett Steel specialise in hollow section and hold extensive range of stock with a variety of sizes and finishes available.

Sheet Metal Laser Cutting Automation Solution

cnc machining turbine blades

Automatic Sheet Metal Loaders – Automation for Laser Cutting

Our Automated Sheet Metal Loaders specifically designed for laser cutting machines help decrease both time and manpower requirements, making them an invaluable asset for any . Fiber laser cutting technology, employing a high-density energy beam for non-contact rapid cutting, has emerged as a revolutionary solution. It offers fast cutting speeds and micron-level precision, with minimal heat .With a fully integrated system for laser cutting, sorting, and storing sheet metal, the ASTES4 is your all-in-one solution for laser automation. Capable of .

Our Automated Sheet Metal Loaders specifically designed for laser cutting machines help decrease both time and manpower requirements, making them an invaluable asset for any metal fabrication business. Fiber laser cutting technology, employing a high-density energy beam for non-contact rapid cutting, has emerged as a revolutionary solution. It offers fast cutting speeds and micron-level precision, with minimal heat-affected zones, thereby reducing material deformation and thermal stress.With a fully integrated system for laser cutting, sorting, and storing sheet metal, the ASTES4 is your all-in-one solution for laser automation. Capable of controlling the entire production process—from loading, cutting, sorting, and unloading

Software has made tracking remnants in sheet metal cutting easier, but operators still manually remove and store them. Now, however, shops have automated options. Two automation units traverse one or more laser cutting machines on two levels. New sheet metal blanks are loaded by the loading unit with suction matrix. Cut sheets are removed from the shuttle table by the unloading unit with rake. The stand-alone version is the simplest way to get started with automated sheet changeover.

cnc machining with ce cert

Productivity & efficiency: Optimize your laser cutting system with laser automationOur proprietary automation systems are the perfect fit to fully exploit our machines’ capabilities. With versatility, modularity and ergonomics at their core, we offer a complete solution for automated material handling making the most of floor space and taking productivity to . Modern laser cutting technology can achieve speeds of more than 400 inches per minute, and that puts pressure on the automation used to load sheets and unload cut parts and skeletons. If the automated material handling system can’t keep up, the fabricator won’t be able to maximize uptime on the laser cutting machine. In the world of sheet metal fabrication, intelligent fabricating with a laser cutting machine can lead to increased productivity and flexibility and reduced setup and tooling costs—as well as faster design and prototype turnaround.

Experts in the sheet metal laser cutting industry – Machines, software and storage. Eagle is a high-tech R&D company specialising in Fiber laser technology and automation solutions for sheet metal cutting based in the centre of Europe.Our Automated Sheet Metal Loaders specifically designed for laser cutting machines help decrease both time and manpower requirements, making them an invaluable asset for any metal fabrication business. Fiber laser cutting technology, employing a high-density energy beam for non-contact rapid cutting, has emerged as a revolutionary solution. It offers fast cutting speeds and micron-level precision, with minimal heat-affected zones, thereby reducing material deformation and thermal stress.

With a fully integrated system for laser cutting, sorting, and storing sheet metal, the ASTES4 is your all-in-one solution for laser automation. Capable of controlling the entire production process—from loading, cutting, sorting, and unloading

Software has made tracking remnants in sheet metal cutting easier, but operators still manually remove and store them. Now, however, shops have automated options.

Two automation units traverse one or more laser cutting machines on two levels. New sheet metal blanks are loaded by the loading unit with suction matrix. Cut sheets are removed from the shuttle table by the unloading unit with rake. The stand-alone version is the simplest way to get started with automated sheet changeover.

Productivity & efficiency: Optimize your laser cutting system with laser automation

Our proprietary automation systems are the perfect fit to fully exploit our machines’ capabilities. With versatility, modularity and ergonomics at their core, we offer a complete solution for automated material handling making the most of floor space and taking productivity to . Modern laser cutting technology can achieve speeds of more than 400 inches per minute, and that puts pressure on the automation used to load sheets and unload cut parts and skeletons. If the automated material handling system can’t keep up, the fabricator won’t be able to maximize uptime on the laser cutting machine. In the world of sheet metal fabrication, intelligent fabricating with a laser cutting machine can lead to increased productivity and flexibility and reduced setup and tooling costs—as well as faster design and prototype turnaround.

Use with Tri-Tel/Quad-Tel, TTP12 Poles, or Round Pole Adapter. Attach these sturdy round fiberglass rods to the top of your pole and you’ll have the perfect perching stations for Martins!

automation sheet metal laser cutting|Sheet Metal Laser Cutting Automation Solution