cnc machine coolant ratio Adding straight water to correct too high a concentration is asking for coolant problems as it destroys the water/oil emulsion. Better to add a 1 or 2% solution and work that . Check out our metal vintage bread box selection for the very best in unique or custom, handmade pieces from our kitchen storage shops.

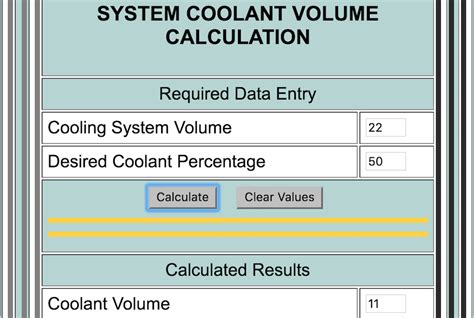

0 · how to calculate coolant concentration

1 · how much coolant in cnc

2 · coolant for cnc

3 · coolant concentration ratio

4 · coolant concentrate ratio cnc

5 · cnc machining coolant ratio

6 · cnc machining coolant conversion chart

7 · cnc machining coolant concentrations

Frankly we can manage without whizzy features like voice activation and user profiles, and while it is convenient to access Netflix via the V6 box and remote, we can still get it via the Roku box we need for other streamers, or the TV's built in 'smart' facilities.

The QualiChem XTREME CUT 251C can be used for milling applications when mixed with water at a ratio of 4-12% (5% (20:1) is a good starting point for beginners). The 770 and 1100 series machines hold 12 gallons of coolant mix .To help you determine the correct coolant concentration for your CNC machine, we have compiled a coolant concentration chart based on industry recommendations and best . Learn how to check and adjust your coolant mixture for optimal CNC machining performance. Follow these steps to maintain the correct ratio of coolant concentrate to water, . Adding straight water to correct too high a concentration is asking for coolant problems as it destroys the water/oil emulsion. Better to add a 1 or 2% solution and work that .

Maintaining the proper concentration of coolant in CNC machines is crucial for achieving optimal performance and prolonging the lifespan of the coolant. The concentration refers to the ratio of coolant to water and can vary .

No matter what type of CNC machining you do, CNC coolants play a critical role. They help increase tool life and offer a better surface finish on the machined parts. By understanding the available coolant types, you can select .

Don't waste your time with the Brix value of the coolant, at least I don't. I run 5-7.5% concentration. I mix up accurate concentrations at 5%, 7.5% and 10%. That way I can calibrate the refractometer and see what concentration I actually have when checking the coolant.The QualiChem XTREME CUT 251C can be used for milling applications when mixed with water at a ratio of 4-12% (5% (20:1) is a good starting point for beginners). The 770 and 1100 series machines hold 12 gallons of coolant mix and need about 2/3 gallons of coolant for each tank refill.

To help you determine the correct coolant concentration for your CNC machine, we have compiled a coolant concentration chart based on industry recommendations and best practices. This chart provides a guideline for coolant concentration levels based on the type of material being machined and the cutting parameters involved. Learn how to check and adjust your coolant mixture for optimal CNC machining performance. Follow these steps to maintain the correct ratio of coolant concentrate to water, ensuring efficient operation and extended tool life. Adding straight water to correct too high a concentration is asking for coolant problems as it destroys the water/oil emulsion. Better to add a 1 or 2% solution and work that toward your goal than adding just water. If ya RTFM, it usually tells you this.

Maintaining the proper concentration of coolant in CNC machines is crucial for achieving optimal performance and prolonging the lifespan of the coolant. The concentration refers to the ratio of coolant to water and can vary depending on the specific machining operation. No matter what type of CNC machining you do, CNC coolants play a critical role. They help increase tool life and offer a better surface finish on the machined parts. By understanding the available coolant types, you can select a . Coolants are vital to CNC machining, not only for maintaining optimal temperatures but also for ensuring effective lubrication, extending tool life, and improving the surface finish of machined parts.There is no one-size-fits-all solution to finding the optimal coolant concentration for CNC machines. The ideal concentration depends on the machining process, the type of coolant being used, and the type of material being cut.

Therefore, it is essential to understand how to use the appropriate CNC machine coolant ratio to achieve the best results. Certain risks are associated with applying coolant concentration lower than the minimum requirements of the CNC machine. Don't waste your time with the Brix value of the coolant, at least I don't. I run 5-7.5% concentration. I mix up accurate concentrations at 5%, 7.5% and 10%. That way I can calibrate the refractometer and see what concentration I actually have when checking the coolant.

The QualiChem XTREME CUT 251C can be used for milling applications when mixed with water at a ratio of 4-12% (5% (20:1) is a good starting point for beginners). The 770 and 1100 series machines hold 12 gallons of coolant mix and need about 2/3 gallons of coolant for each tank refill.

To help you determine the correct coolant concentration for your CNC machine, we have compiled a coolant concentration chart based on industry recommendations and best practices. This chart provides a guideline for coolant concentration levels based on the type of material being machined and the cutting parameters involved.

Learn how to check and adjust your coolant mixture for optimal CNC machining performance. Follow these steps to maintain the correct ratio of coolant concentrate to water, ensuring efficient operation and extended tool life. Adding straight water to correct too high a concentration is asking for coolant problems as it destroys the water/oil emulsion. Better to add a 1 or 2% solution and work that toward your goal than adding just water. If ya RTFM, it usually tells you this.

car chassis metal thickness

Maintaining the proper concentration of coolant in CNC machines is crucial for achieving optimal performance and prolonging the lifespan of the coolant. The concentration refers to the ratio of coolant to water and can vary depending on the specific machining operation. No matter what type of CNC machining you do, CNC coolants play a critical role. They help increase tool life and offer a better surface finish on the machined parts. By understanding the available coolant types, you can select a .

Coolants are vital to CNC machining, not only for maintaining optimal temperatures but also for ensuring effective lubrication, extending tool life, and improving the surface finish of machined parts.There is no one-size-fits-all solution to finding the optimal coolant concentration for CNC machines. The ideal concentration depends on the machining process, the type of coolant being used, and the type of material being cut.

how to calculate coolant concentration

car tv show cnc machine

cardboard box corner metal reinforcement

cardello electric flip bell box covers

cardboard box metal wiki

Some of my accessories have instructions to ground to the negative terminal on the battery while others just need a chassis ground. My logic is that the negative battery terminal is grounded to the chassis so the two must be one of a kind.

cnc machine coolant ratio|how to calculate coolant concentration