cnc machining axis 3-Axis vs. 5-Axis: Pros and Cons. The main difference between these two types of CNC machines is the number of ways they can move their tool: one has three, and one has five. This seemingly small factor, however, makes .

The turret option (-T) adds one servo axis to the Bender module, for automatic and programmable bending tool-change along with a second bending pin. This provides the flexibility to programmatically change the tool that the wire is getting bend .

0 · cnc with rotary axis

1 · cnc machine axis locations diagram

2 · cnc machine axis direction

3 · cnc axis explained

4 · cnc axis chart

5 · axis identification in cnc machine

6 · 4 axis cnc milling machines

7 · 4 axis cnc machine cost

Crafted from durable pre-galvanized steel, these boxes are designed to house wiring devices such as switches or outlets. With RACO's Switch Electrical Boxes, convenience is key. The device mounting holes are pre-tapped to accept 6-32 device screws, making installation a breeze.

Understand the unique advantages of 3-axis, 4-axis, and 5-axis CNC machining for your projects. Learn how each configuration impacts precision, design complexity, and cost, with expert .

In this comprehensive guide to CNC machine axes, we have explored the fundamentals of each axis, their functions, and applications in the realm of CNC machining. By understanding the .

cnc with rotary axis

cnc machine axis locations diagram

Learn to become a CNC Machinist or .more. Titan Gilroy explains the CNC "Axis of Movement". Revolutionary CNC Education all available for FREE.3-Axis CNC Machining. 3-axis CNC machining evolved from rotary filing (think dental drill 😬). With a 3-axis CNC machine, the workpiece is stationary while the cutting tool moves across the X-, Y-, and Z-axes. Axes of a CNC milling machine. Taking the most common vertical CNC mills as an example, 3 axes control the linear motion of the workpiece and the spindle, the X axis moves left and right, the Y axis moves forward and . 3-Axis vs. 5-Axis: Pros and Cons. The main difference between these two types of CNC machines is the number of ways they can move their tool: one has three, and one has five. This seemingly small factor, however, makes .

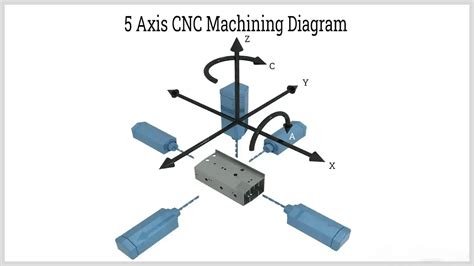

The C-axis is particularly useful in machining operations such as milling, drilling, and off-center operations. By programming the C-axis, the workpiece can be rotated to a desired angle or position, allowing for the .5-Axis CNC Machining. 5-Axis, simultaneous machining delivers superior Dimensional tolerance control and improved Product quality by eliminating cumulative Dimensional Stackup errors introduced by multiple setups. Ideal for .In 5-axis CNC machining, the B-axis typically refers to the rotation around the Y-axis, while the C-axis refers to the rotation around the Z-axis. These rotary axes can be positioned on the machine table (trunnion-style) or the spindle head (swivel-style). The combination of these axes with the linear X, Y, and Z axes allows the cutting tool to .Multi-axis CNC machining centers come in three variations: 5-axis indexed CNC milling, continuous 5-axis CNC milling and mill-turning centers with live tooling. These systems are essentially milling machines or lathes enhanced with .

This versatile 5-axis universal machining center can position parts to nearly any angle for 5-sided (3+2) machining, or provide simultaneous 5-axis motion for contouring and complex machining. Haas VF-2SS + TR160M Codes “G” stands for Geometry; hence, the G-Code commands are responsible for the movements of the machine that create the geometry of the part.“M” stands for Machine (or Miscellaneous), and the M-Codes are responsible for Machine commands that cause particular operations of the equipment. Unlike G-codes, which can appear multiple times on the same . 5-axis machining has quickly become a game-changer in CNC manufacturing, offering unprecedented flexibility, speed, and precision. By allowing a machine to move a workpiece along five axes simultaneously, 5-axis machining overcomes the limitations of traditional 3-axis methods, which require multiple setups for complex geometries.

Titan Gilroy explains the CNC "Axis of Movement".Revolutionary CNC Education all available for FREE. Learn to become a CNC Machinist or a CNC Programmer thro. CNC mills are usually 3 axis machines and lathes are 2 axis. Both types of machines can have more axes but let’s keep things simple. . Place your hand in front of your CNC machine, aligned with the machine’s spindle, and you’ll see the axes line up perfectly. The thumb is the X-axis. For more complex parts, 5-axis machining is better. What are the “extra” axes on a 5-axis machine? In addition to the traditional three axes, 5-axis machining also uses two rotary axes: A-, B-, and/or C-. A-axis: Rotation around the X-axis; B-axis: Rotation around the Y-axis; C-axis: Rotation around the Z-axis

Four-axis CNC machining adds an additional rotational axis, which imparts enhanced flexibility and machining capabilities. Here are some of the benefits of a four-axis machine: Increased complexity: With the addition of a rotational axis, four-axis machines can produce more complex shapes and geometries, including cylindrical and contoured parts. 3+2 machining, also known as 5-sided machining or indexed 5-axis machining, is a technique where a 5-axis CNC machine is used, but the cutting tool does not move simultaneously in all five axes. Instead, the machine positions the workpiece in a fixed orientation using two rotational axes and then proceeds with the machining operation using the . In addition, Mazak previously launched a new generation of multi-tasking machine INTEGREX i-500. It not only has the turning, milling and 5-axis machining capabilities of composite machining equipment, but also integrates the capabilities of special machine tools such as gear forming, hobbing, and long drill machining.Machining Complex Shapes: Unlike traditional 3-axis machines, 5-axis machines can move and rotate the tool and workpiece simultaneously, creating intricate parts with a high degree of accuracy. Reduced Setups and Fixtures: The ability to access multiple sides of the workpiece minimizes the need for various setups and specialized fixtures. This translates to faster .

cnc machine axis direction

The Power of 5-Axis CNC Machining. Traditionally, CNC machining involved three axes: X, Y, and Z. While this allowed for effective milling and drilling, it presented limitations in terms of reaching and machining complex geometries. This is where 5-Axis CNC machines step in. By adding two rotary axes (A and B), these machines can tilt the . 5-axis CNC machining is a suitable method for hook surface machining, unusual shape machining, hollow machining, oblique hole, etc. While 5-sided machining is similar to but more capable than 3-axis machining. It can .Runsom Precision offers a wide range of custom online CNC machining services, including 3, 4, and 5-axis CNC milling and CNC turning, grinding, EDM, laser cutting, and others.There are abundant CNC machining services from design, . 3-axis CNC Machining. The least complex 3-axis CNC machining technique is the one having limited movements to the X, Y, and Y coordinate confinements. It is suitable for primary parts and standard form. 4-axis CNC Machining 4-axis CNC machining has an extra movement, which is usually rotational movement along the x-axis, enabling more advanced .

The five axes of a 5-axis CNC machine are X, Y, Z (linear) and A and B (rotational). Understanding the unique function of each allows machinists to unlock the full potential and capabilities of the machine. In many machines, the X-axis moves left to right and is most useful for basic linear cuts. The Y-axis moves front to back perpendicular to . Index finger is the Y-axis. Thumb is the X-axis. How a CNC Machine Uses Coordinates. Using the Cartesian coordinate system, we control CNC machines along each axis to transform a block of material into a finished part. Although it’s difficult to describe axes using relative .

3-Axis CNC Machining. A 3-axis CNC machine, such as a lathe, mill, or machine tool center, moves its tool (whether it’s a cutter, drill, or mill) along the X (left to right), Y (front to back), and Z (up and down) axes. More specifically, it can move either horizontally (X-Y axes) or vertically (Z axis) to control the cutting depth.

A 5-axis CNC machine, also known as a 5-axis machining center, is a sophisticated computer numerically controlled (CNC) machining equipment. It expands upon the capabilities of traditional 3-axis CNC machines (X, Y, and Z axes) by incorporating two additional rotary axes (commonly designated A, B, or C). The 4-axis CNC machining is the next logical upgrade of 3-axis machining.It features 3 standard axes and one rotary axis, which move in different directions on the stationery working table. The X-axis, for instance, moves from right to left,the Y-axis from top to bottom,and the Z-axis up and down perpendicular to the work table, while the A .COMPONENT CAPABILITIES. Miller CNC machines components to customer specifications. Our scope of work includes machining parts made from bar, plate, forgings and castings using 3 Axis, 4 Axis, and 5 Axis mills along with CNC lathes. We primarily machine Inconel™, titanium, stainless steel, and exotic alloys in production lot sizes of 50-1000 pieces and we support . Why Choose 5-Axis CNC Machining Over Other Techniques. Deciding between 5-axis machining centers and other techniques can be pretty challenging. There are many factors to consider to ensure you make the best choice. Here’s a comparison between this technology and other methods. 5-Axis CNC Machining vs. 3+2-Axis CNC Machining

Multi-Axis Machining is located in Cottonwood, Arizona. Able to provide services using manual as well as cnc machining. Give us a chance to earn your business. . Machine shop providing CNC and manual machining services. Where we strive to build long term relationships. Introducing Multi-Axis Machining - The Future of Precision Manufacturing! . Using an older Haas control, I found that the quick return to A0 didn't really unwind a multi-turn wind up. It would still have to unwind. The method I found worked was to reset the A axis position with G92 after a single axis rapid return to X0. I did not want to G00X0 A0 because that forces the unwind of A So G00 X0 G92 A0 next cut, etc. Types of CNC Machining Axis Configurations 3 Axis CNC Machines. The 3 Axis CNC Machine is the most basic configuration, moving along the X, Y, and Z Axes. It’s commonly used for simpler, flat parts and basic drilling and milling. While it’s ideal for low-complexity work, it may require multiple setups to complete parts with complex .

cnc axis explained

cnc axis chart

axis identification in cnc machine

4 axis cnc milling machines

Flower box liners in PVC, Coco Coir and various metal materials. Our metal & plastic window box liners come in all price points &styles to suit any project.

cnc machining axis|4 axis cnc milling machines