cnc drilling machine specifications In this comprehensive guide, we will dive deep into the world of CNC drilling machine specifications, exploring the key features, capabilities, and potential applications. CNC mills or CNC milling machines produce parts of nearly any shape from soft metals like aluminum, harder metals like steel, and plastics such as acetal. eMachineShop offers cost-effective milling service whether you need a single part, batch of .

0 · types of cnc drilling

1 · purpose of cnc drilling

2 · process of cnc drilling

3 · how deep is a cnc drill

4 · cnc drilling precision

5 · cnc drilling machine

6 · cnc drilling depth

7 · cnc drilling definition

XTJ offers a complete copper CNC machining service and can produce complex copper parts in C110 and C101. Copper parts are corrosion resistant and versatile and can be used for applications requiring electrical conductivity and higher .

types of cnc drilling

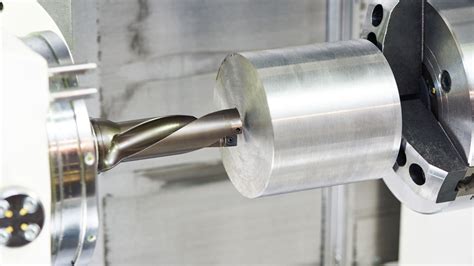

CNC drilling is a computer-controlled subtractive machining process, in which a rotating drill bit creates a round hole in a stationary workpiece (maybe wood, metal, plastic, or composite).In this comprehensive guide, we will dive deep into the world of CNC drilling machine specifications, exploring the key features, capabilities, and potential applications. CNC (Computer Numerical Control) vertical drilling machines are pivotal in modern manufacturing, offering precision, efficiency, and versatility across various industries. These .CNC drilling is a precision machining process that revolves around using rotating cutting tools to create perfectly round holes in a stationary workpiece. The primary objectives of drilling range from achieving aesthetic precision to preparing .

What Is a cnc drilling machine and How Does It Work? A computer numerical controlled (CNC) drilling machine is an automated drilling device that drills holes into various materials accurately and consistently as dictated by a . CNC drilling is a precise CNC machining method that employs computer numerical control (CNC) where drill bits are utilized to bore holes into a material. Unlike manual drilling, CNC drilling harnesses the power of . Unlock the secrets of CNC drill mastery! This guide covers efficient hole drilling techniques, machine setup, and best practices for precision in CNC applications.

Triple axis drilling and milling leads to processing a complete profile in record time. Powered by high-speed 25 horsepower Siemens spindle motors, this strength captures industry-leading hole penetration times and each drilling . CNC drilling, or Computer Numerical Control drilling, is a precise and efficient machining process that automates the drilling of holes in various materials. It involves using a . Modern machining relies heavily on CNC drilling, which seamlessly integrates precision and efficiency to transform the manufacturing process. This article delves deep into . CNC drilling is a computer-controlled subtractive machining process, in which a rotating drill bit creates a round hole in a stationary workpiece (maybe wood, metal, plastic, or composite).

In this comprehensive guide, we will dive deep into the world of CNC drilling machine specifications, exploring the key features, capabilities, and potential applications. CNC (Computer Numerical Control) vertical drilling machines are pivotal in modern manufacturing, offering precision, efficiency, and versatility across various industries. These machines automate the process of drilling holes in diverse .CNC drilling is a precision machining process that revolves around using rotating cutting tools to create perfectly round holes in a stationary workpiece. The primary objectives of drilling range from achieving aesthetic precision to preparing components for accommodating screws and bolts.

What Is a cnc drilling machine and How Does It Work? A computer numerical controlled (CNC) drilling machine is an automated drilling device that drills holes into various materials accurately and consistently as dictated by a computer program. CNC drilling is a precise CNC machining method that employs computer numerical control (CNC) where drill bits are utilized to bore holes into a material. Unlike manual drilling, CNC drilling harnesses the power of computers to control the drill bits’ movements, ensuring accuracy and consistency that manual operations can’t match.

Unlock the secrets of CNC drill mastery! This guide covers efficient hole drilling techniques, machine setup, and best practices for precision in CNC applications.

Triple axis drilling and milling leads to processing a complete profile in record time. Powered by high-speed 25 horsepower Siemens spindle motors, this strength captures industry-leading hole penetration times and each drilling axis utilizes ball screw feed positioning.

CNC drilling, or Computer Numerical Control drilling, is a precise and efficient machining process that automates the drilling of holes in various materials. It involves using a computer program to control the movement of the drill bit with high accuracy.

Modern machining relies heavily on CNC drilling, which seamlessly integrates precision and efficiency to transform the manufacturing process. This article delves deep into the fundamental principles, operational mechanisms, and extensive utilization of CNC drilling. CNC drilling is a computer-controlled subtractive machining process, in which a rotating drill bit creates a round hole in a stationary workpiece (maybe wood, metal, plastic, or composite).In this comprehensive guide, we will dive deep into the world of CNC drilling machine specifications, exploring the key features, capabilities, and potential applications. CNC (Computer Numerical Control) vertical drilling machines are pivotal in modern manufacturing, offering precision, efficiency, and versatility across various industries. These machines automate the process of drilling holes in diverse .

CNC drilling is a precision machining process that revolves around using rotating cutting tools to create perfectly round holes in a stationary workpiece. The primary objectives of drilling range from achieving aesthetic precision to preparing components for accommodating screws and bolts.

purpose of cnc drilling

What Is a cnc drilling machine and How Does It Work? A computer numerical controlled (CNC) drilling machine is an automated drilling device that drills holes into various materials accurately and consistently as dictated by a computer program. CNC drilling is a precise CNC machining method that employs computer numerical control (CNC) where drill bits are utilized to bore holes into a material. Unlike manual drilling, CNC drilling harnesses the power of computers to control the drill bits’ movements, ensuring accuracy and consistency that manual operations can’t match.

Unlock the secrets of CNC drill mastery! This guide covers efficient hole drilling techniques, machine setup, and best practices for precision in CNC applications.Triple axis drilling and milling leads to processing a complete profile in record time. Powered by high-speed 25 horsepower Siemens spindle motors, this strength captures industry-leading hole penetration times and each drilling axis utilizes ball screw feed positioning. CNC drilling, or Computer Numerical Control drilling, is a precise and efficient machining process that automates the drilling of holes in various materials. It involves using a computer program to control the movement of the drill bit with high accuracy.

how to install plastic outdoor electrical outlet boxes

Pierce Aluminum can provide Angle products with leg lengths ranging from .

cnc drilling machine specifications|cnc drilling precision