cnc machining fixtures CNC fixtures are work-holding tools for stability and positioning. They are often used in securing, supporting, or fixing a workpiece appropriately on the CNC machine. A CNC fixture is an essential tool that facilitates .

A junction box provides a safe, code-compliant space for housing cable connections for outlets, switches, or splices. They prevent potential electrical shocks, and keep sparks from spreading to flammable surroundings.

0 · workholding fixtures for machining

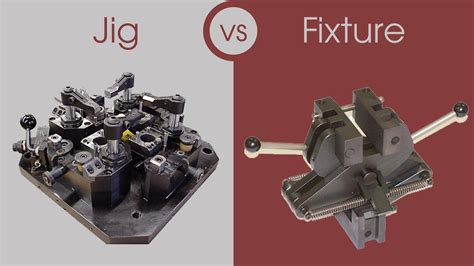

1 · types of fixtures and jigs

2 · tapped table fixture cnc machine

3 · list of jigs and fixtures

4 · jigs and fixtures for cnc

5 · holding fixtures for cnc machines

6 · fixture plates for cnc mills

7 · fixture plate for milling machine

Different Types of Sheet Metal Operations are: Shearing Operation; Blanking & Fine Blanking Operation; Punching Operation; Piercing Operation (poking lots of holes in) Operation Perforating Operation; Slotting Operation; .

Learn how to design effective CNC fixtures for your machining projects with this guide. Find out the different types of fixtures, their uses, and best practices for creating and testing them. See moreWhat is a fixture? A fixture is defined as an object that holds another object securely in place so that it can be machined or worked on more easily.Fixtures come in all shapes and sizes, . See more

CNC fixtures come in various shapes and sizes, each with its own unique purpose and function. Here is a list of some common types of CNC fixtures: See more

new electrical meter box

Make sure your CNC machine is properly set up and calibratedbefore using your new fixture. Otherwise, you may end up with inaccurate results. Read the instructions that come with your CNC fixture carefully. Familiarize yourself with all of the controls and . See moreSelecting the right CNC fixtures is crucial for achieving accurate and efficient machining operations. The first step in selecting the right machining fixture is to determine the type of workpiece being machined and the required machining operations. This will . See more CNC fixtures are work-holding tools for stability and positioning. They are often used in securing, supporting, or fixing a workpiece appropriately on the CNC machine. A CNC fixture is an essential tool that facilitates . Thus, they can be placed right on the CNC machine and milled easily using a fixture plate, mod vises, and other clamps. 5. Multi-Part Workholding. Multi-part machining workflows allow machinists to program .

With the application of more and more CNC machine tools and machining centers, . lathe fixtures, drilling machine fixtures, boring machine fixtures and bed fixtures. According to different uses, it can be divided into .

workholding fixtures for machining

Fixtures for CNC machining are very important. Fixture design is generally in parts machining process in accordance with the specific requirements of one process. In the process of formulating the technology, we will take the .CNC Machining Fixtures. Our CNC design and manufacturing process uses the latest 3d technology and software to ensure that however complex the final product needs to be, high accuracy is always maintained.

We are Manufacturer, Supplier, Exporter of CNC Machining Fixtures. Our setup is situated in Pune, Maharashtra, India. Machining fixture is all about accuracy, high productivity, repeatability, minimum possible time & ease of placing and removal of the part from the fixture. All the factors mentioned and many others are minutely taken care at . Therefore, an in-depth study of thin-walled parts CNC machining fixture structure design has important theoretical significance and practical application value. This paper will focus on the fixture structure design in the CNC machining of thin-walled parts, aiming to provide theoretical guidance and technical support for the high-precision and .

A pair of milling vises sit side by side on a machine table.. It’s not too much of a stretch to say that the most popular Workholding Solution today is the Milling Vise. While there are many manufacturer’s of such vises, the poster child is Kurt who shipped their first “Kurt Vise” in the 1950’s. For much more in-depth coverage of Machinist Vises, see our Complete Guide to .

CNC machine tool fixtures in a variety of forms, each enterprise according to the characteristics of their products and production needs to use the corresponding fixture system. Flexible fixture system with high precision, high rigidity, modularity, generalization and rapid response and other advantages, especially suitable for product batch .Custom CNC Fixture Design. PEKO’s CNC machining division employs dedicated tooling engineers for its machining fixture design.. To fully utilize our precision parts and assemblies business, PEKO must produce hundreds of custom designed machining fixtures every year.

A drilling fixture is a type of CNC machine tool that is commonly used in automated production processes. This fixture is a machining fixture used to hold a workpiece for CNC machine tools with linear axes, such as vertical mills and horizontal mills. Boring fixtures: Boring Fixtures provide a CNC machining center with a boring bar setup.

The manufacturing industry largely depends upon Precision, accuracy, and efficiency. CNC machining is a revolutionary technology to achieve all of these quickly. This automated method produces intricate components of the machine with ease and flexibility. Its ability to achieve accuracy depends upon many tools and they are necessary to handle a .Combine with setup studs or bolts to mount fixtures to machine tables. 181 products. T-Slot Covers. Snap into T-slots to block chips, debris, and small parts from falling in. 6 products. . CNC routers, and drill presses. 17 products. Spring Stops. Push back against workpieces to hold them in place against stops and rails. 22 products.Manufacturer of Precision Machined Components, Developments of Tools(Fixtures, and form tools) and machining. TRIMURTHI CNC MACHINING is a trusted Manufacturer and Supplier of Industrial Products in Bangalore Peenya. Our Industrial Products comprises of Aluminium Housings, Aluminum Control Arms, Bearing Bushes, CNC Turned Component, CNC Turned .

What is a CNC Fixture: Before we proceed with the types of CNC fixtures and how you can pick the right one for CNC machining, it’s essential to know what CNC fixtures are in the first place. Precisely speaking, CNC fixtures are an agent of stability and placement. It is used as a tool in CNC machining, known as a work-holding device with several applications. Boring Fixture. CNC boring is a CNC machining process in which a tool is used to enlarge a hole that has been drilled using CNC drilling. The fixture used in this process is a CNC boring fixture. Grinding Fixture. CNC grinding .

nema metal enclosures locking outdoor

Custom workholding fixtures are great for production. Designing fixtures that hold multiple parts ensures process reliability, fewer setups, and operations. . I use the same strategy for drilling/reaming my fixture plates and everything lines up nicely. My fixtures each have 2x 0.3750" dowel pins protruding from the bottom of the fixture plate that engage with the holes in the table. Don't make the dowel pins stick out too much or you'll have a hell of a time getting the fixture plate back off the table.1. Collets – A key component of CNC turning, a collet works in tandem with the spindle. When machining, collet chucks provide a consistent gripping force, enabling you to safely operate the machine at higher RPMs and reducing your run-time.If you are interested in becoming a CNC Machinist and obtaining your CNC Machining certificate from Dallas College-Richland, then SUBMIT RESUME! Submit Resume. GARLAND SERVICE COMPANY . Our team uses your specific printed circuit board design to machine and assemble tooling, fixtures, and ancillary pieces for any PCBA processes you may need .

Machining Fixtures: Engineered to be Advanced. Is your workholding holding you back? Reach out for a free consultation. Our application experts will ask the right questions so our fixture designers can concept advanced workholding systems that get you set up for success. Discover high-quality clamping fixtures for CNC machining. Enhance precision and stability with our custom solutions tailored to your specific manufacturing needs. Skip to content +86 13412350358; [email protected]; Mon - Sat: 8:00 - 17:30; Capabilities. Custom CNC Machining. CNC Machining. CNC Milling.

types of fixtures and jigs

tapped table fixture cnc machine

Industrial Fixtures. Fixtures are the support devices that are widely used in manufacturing industry. We are one of the well known manufacturers of Fixtures, which are categorized into various models like Turning and Machining Fixtures, Custom Work holding Fixtures, Tombstone Fixtures, Indexing Fixtures and Fixtures for CNC Machines. Exploring Various Types of Fixtures. Fixtures are integral to machining processes, offering stability and support to workpieces during manufacturing operations. . How the CNC Machining Industry is Revolutionizing Manufacturing and Top Industries; Types of CNC Machine Tools and Their Applications in Precision Machining; Understanding Acetal .Custom CNC Fixtures by AME. Leverage AMROK® expertise as a turn-key workholding resource. Improve your machining processes with engineered dedicated manual fixtures, or fully automated hydraulic fixtures built from the ground up. . Custom machining fixtures designed for the highest productivity. Fully-automated hydraulic workholding; Tips for Machining with Vacuum Chucks and Fixtures Tip #1: Plan how to avoid releasing vacuum during roughing. . [ CNC Machining Plywood ] Quoting Million Worth of Aerospace Work With G-Wizard. Dropbox: Awesome File Sharing Tool for Multiple PC’s. Tapping Arm [DIY Shopmade]

netherlands roll down door and window cover metal box outside

Today, we’re diving into a crucial aspect of precision machining: designing effective CNC fixtures. Simply put, a fixture is a device or assembly used to locate and secure a workpiece during machining operations. It ensures that your part stays put, allowing the CNC machine to do its job without any movement or vibration. . Discover high-quality clamping fixtures for CNC machining. Enhance precision and stability with our custom solutions tailored to your specific manufacturing needs. Skip to content +86 13412350358 [email protected] Mon - Sat: 8:00 - 17:30; Capabilities. Custom CNC Machining. CNC Machining. CNC Milling.

list of jigs and fixtures

Here's my short (london-centric) street-cabinet identification guide, sorted by most-frequent to least: BT Cabinet: Almost always green, standard double-door design with hip roof. Normally well maintained unless a car's smashed it.

cnc machining fixtures|fixture plates for cnc mills