purged and pressurized enclosures for electrical equipment Stay informed and participate in the standards development process for NFPA 496. $21.95

0 · what is a purge system

1 · what is a purge pressure

2 · purge vs pressurization

3 · purge and pressurization function

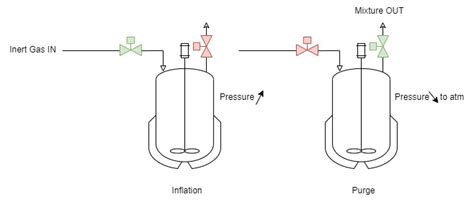

4 · pressure purge systems

5 · pressure pressurization system

6 · pressure gas purge system

$12.99

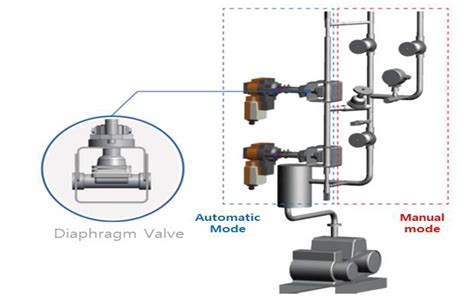

Stay informed and participate in the standards development process for NFPA 496. When supplied with a source of “protective gas” (clean instrument air or an inert gas) at a predetermined pressure, the primary function of the purge and pressurization system .Purge and Pressurization is a protection method used with Type 4, 4X and 12 (IP54 recommended minimum) enclosures. The enclosure is initially purged to remove any internal explosive gases or dust. Once this is accomplished, the .Many types of enclosures can be used for purge and pressurization applications, but there are attributes that create a more robust and economical system. As electrical enclosures are rated .

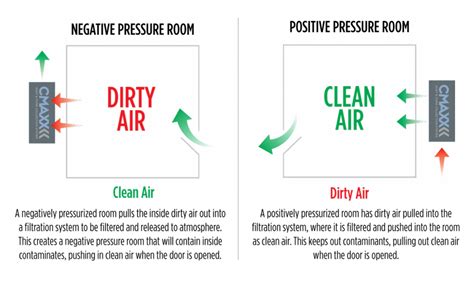

FPN 2 to Sec. 500-4 (d) in the NEC refers to NFPA 496-1998 (Purged and Pressurized Enclosures for Electrical Equipment) for .Purging is the process of supplying enclosures with compressed air or inert gas at the proper flow and pressure in order to reduce the hazardous gas inside the enclosure to a safe level. Pressurization is the process of bringing .

Expo’s purge and pressurization systems will allow your electrical equipment to be used in most hazardous areas with virtually no limitations on the type of equipment that can be protected. Our systems are approved for use in gas . Standard for Purged and Pressurized Enclosures for Electrical Equipment. This standard applies to purging and pressurizing for the following: (1) Electrical equipment located .

This new edition provides the following changes: Revisions to the definitions for Type X Pressurizing, Type Y Pressurizing, and Type Z Pressurizing clarify that pressurizing keeps a .Standard for Purged and Pressurized Enclosures for Electrical Equipment. 2021. IMPORTANT NOTICES AND DISCLAIMERS CONCERNING NFPA®STANDARDS. NFPA®codes, .nfpa4962017-NFPA 496 Standard for Purged and Pressurized Enclosures for Electrical Equipment, 2017 edition-1.1 Scope. 1.1.1 This standard applies to purging an . HOME; PRODUCTS. Publisher Collections; . Electrical .

Help Reduce the Potential for Fire in Purged and Pressurized Enclosures. Electrical equipment fires, explosions, and other dangers relating to the ignition of a flammable atmosphere pose a significant threat to people and property. .NFPA 496, Standard for Purged and Pressurized Enclosures for Electrical Equipment This standard provides information on the methods for purging and pressurizing electrical equipment enclosures to prevent ignition of a flammable .electrical equipment inside an enclosure. The goal is to ensure that once an enclosure is purged and pressurized with a protective gas supply, the enclosure can only then be energized or powered up. The protective gas supply needs to be free of any hazardous or explosive gas and have the capacity to sustain the purge and pressurization process. In

In 1967, the NFPA Technical Committee on Electrical Equipment in Chemical Atmospheres established recommended practices, entitled “NFPA 496 – Purged and Pressurized Enclosures for Electrical Equipment.” Since then, the NFPA has expanded their document by adding recommendations for enclosure ventilation and dilution. You get comprehensive criteria for designing and operating purged and pressurized electrical equipment enclosures to minimize hazards in the presence of flammable materials. This standard applies to purging and pressurizing for the Electrical equipment located in areas classified as hazardous by Article 500 or Article 505 of NFPA 70, National .

By Chris Romano, product portfolio manager for Purge and Pressurization, Pepperl+Fuchs, Inc.. Editor's Note: This article is adapted from a white paper, "Avoid These Eight Common Mistakes When Purging and Pressurizing Enclosures." Download the free, full white paper with additional in-depth information about mistakes and how to avoid them.

Electrical equipment located in spaces where flammable or combustible materials are present must somehow protect against ignition of these materials. . Location of the sensor that monitors the enclosure pressure is important in preventing “false” alarms. . Z type purge systems are used in a Division 2 area where non-hazardous rated . You get comprehensive criteria for designing and operating purged and pressurized electrical equipment enclosures to minimize hazards in the presence of flammable materials. This standard applies to purging and pressurizing for the Electrical equipment located in areas classified as hazardous by Article 500 or Article 505 of NFPA 70, National . The internal equipment can be rated for general-purpose, non-hazardous locations. The purge/pressurization system and the electrical power source must be interlocked since a power failure to the pressure system and not the internal equipment could result in an explosion due to the continuous presence of a hazardous atmosphere in Division I areas.

what is a purge system

Expo is a world leader in the design and manufacture of purge & pressurization systems for electrical enclosures, analysers and other equipment. All electrical equipment used in hazardous areas is required to be certified using a recognised protection method. While users may have a choice of methods for protection, purge and pressurization (Ex p) is the simplest and most .

NFPA 496: Standard for Purged and Pressurized Enclosures for Electrical Equipment 2017 [National Fire Protection Agency] on Amazon.com. *FREE* shipping on qualifying offers. . NFPA 496: Standard for Purged and Pressurized Enclosures for Electrical Equipment 2017 Unknown Binding . by National Fire Protection Agency (Author) 5.0 5.0 out of 5 .NFPA 496: Purged and Pressurized Enclosures for Electrical Equipment contains requirements for the design and operation of purged and pressurized electrical equipment enclosures. This protection technique is used in Class I and Class II hazardous (classified) locations to reduce or prevent the presence of flammable materials within electrical .Scope. 1.1 Scope. 1.1.1 This standard applies to purging and pressurizing for the following: (1) Electrical equipment located in areas classified as hazardous by Article 500 or Article 505 of NFPA 70 (2) Electrical equipment containing sources of flammable vapors or gases and located in either classified or unclassified areas

Purge and Pressurization is a protection method used with Type 4, 4X and 12 (IP54 recommended minimum) enclosures. The enclosure is initially purged to remove any internal explosive gases or dust. Once this is accomplished, the .

The international standards IEC 60079-2 and NFPA 496 define the regulations for purged and pressurized enclosures for the protection of electrical equipment, such as switch and control cabinets, analysis devices, . energy .NFPA 496 NFPA496 is the specific National Fire Protection Association “Standard for Purged and Pressurized Enclosures for Electrical Equipment”. AB-CO PURGE Y-Purge and Z-Purge systems comply with this standard. This standard applies to purging and pressurizing for the following: Electrical equipment located in areas classify.ed as hazardous by NFPA 70.prior to energizing the electrical equipment inside the enclosure. The goal is to ensure that once an enclosure is purged and pressurized with a protective gas supply, only then can the enclosure be energized or powered up. The protective gas supply needs to be free of any hazardous or explosive gas and have the capacity toHelp identify and minimize potentially deadly hazards and better safeguard facilities by referencing and complying with NFPA 496, Standard for Purged and Pressurized Enclosures for Electrical Equipment. This critical standard offers protection techniques applicable to Class .

predetermined pressure, the primary function of the purge and pressurization system is to ensure a . Standard for Purged and Pressurized Enclosures for Electrical Equipment. Chapter 3 of this standard defines many of the specific terms used when researching purge and pressurization systems. ForRequirements included in Chapters 4, 5 and 7 of NFPA 496-2003, Purged and Pressurized Enclosures for Electrical Equipment, provide the necessary guidelines for preventing the entry of flammable vapors or gases into the control room. Naturally, the enclosures in the control room must be capable of housing the electrical components.

the purged and pressurized protection technique shall be permitted for equipment in any hazardous (classified) location for which it is _____ . and where breakdown or faulty operation of process equipment might cause electrical equipment failure simultaneously Code Ref. 500.5(B)(1) . Enclosures used in class 1 division 1 and 2 locations are .

Employers must also ensure that when equipment approved for Class I, Group B atmospheres is not commercially availalbe, the equipment is (1) purged or ventilated in accordance with NFPA No. 496-1967, Standard for Purged Enclosures for Electrical Equipment in Hazardous Locations, (2) intrinsically safe, or (3) approved for Class I, Group C . junction box b. electrical safety box c. enclosure d. wiring . 4 b. 4X c. 6 d. 7. 7. A(n) _____ enclosure is a nonhazardous enclosure that is pressurized and purged with air to allow it to be to be used in hazardous areas. . IEEEE. NEC _____ protection is where the electrical equipment, under normal or abnormal conditions, is incapable of .

what is a purge pressure

predetermined pressure, the primary function of the purge and pressurization system is to ensure a . Standard for Purged and Pressurized Enclosures for Electrical Equipment. Chapter 3 of this standard defines many of the specific terms used when researching purge and pressurization systems. For

496–2 PURGED AND PRESSURIZED ENCLOSURES FOR ELECTRICAL EQUIPMENT The NFPA Technical Committee on Electrical Equipment in Chemical Atmospheres wishes to gratefully acknowledge the efforts of the Instrument Society of America, through its Committee SP12, in the development of the basic requirements for purged and pressurized enclosures. Buy NFPA 496 : 2017 PURGED AND PRESSURIZED ENCLOSURES FOR ELECTRICAL EQUIPMENT from Intertek Inform. Customer Support: +1 416-401-8730. Login to i2i Subscription Intertek.com. . PURGED AND PRESSURIZED ELECTRICAL EQUIPMENT FOR HAZARDOUS (CLASSIFIED) LOCATIONS I.S. EN ISO 10439:2002: PETROLEUM, .

Please visit a Menards store for information and to purchase. The Hillman® zinc-plated steel sheets have applications for gutter repair, auto repair, flashing, and duct work. These sheets feature an electroplated zinc plating that gives the steel a clean, bright look while also protecting it from rust.

purged and pressurized enclosures for electrical equipment|pressure pressurization system