cnc lathe machine operation The primary CNC lathe machine operations are: Cutting involves separating large amounts of material from a workpiece with a sharp-edged cutting tool. Deformation involves physically changing the shape of a workpiece by removing material from it. $35.99

0 · turning operations on lathe machine

1 · parts of cnc lathe machine

2 · cnc lathe work

3 · cnc lathe process

4 · cnc lathe parts

5 · cnc lathe machine working

6 · centering operation on lathe machine

7 · center lathe operations

This review examines the usage and working of the Xiaomi Square Box II Bluetooth Speaker, which is capable of delivering loud sound in detail.

The primary CNC lathe machine operations are: Cutting involves separating large amounts of material from a workpiece with a sharp-edged cutting tool. Deformation involves physically changing the shape of a workpiece by .Each of these components plays a crucial role in the operation of a CNC lathe machine, working together to produce high-quality, precision-machined parts. Next, we’ll explore the various . What are the different operations that can be performed on a lathe machine? Here we’ll go through the types of the basic machining processes on a CNC lathe. The primary CNC lathe machine operations are: Cutting involves separating large amounts of material from a workpiece with a sharp-edged cutting tool. Deformation involves physically changing the shape of a workpiece by removing material from it.

Each of these components plays a crucial role in the operation of a CNC lathe machine, working together to produce high-quality, precision-machined parts. Next, we’ll explore the various types of CNC lathe machines and how they differ in terms of capabilities and applications.

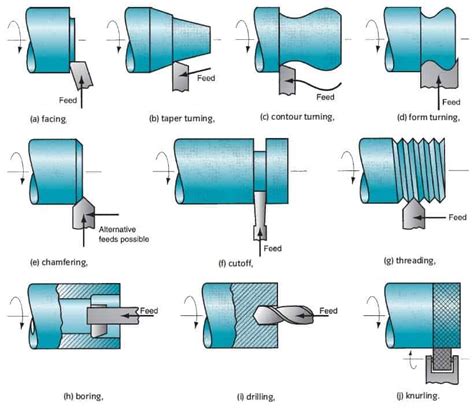

Lathe machine operations are turning operation, facing operation, taper turning operation, knurling operation, grooving operation with PDF. What is CNC lathe Machine? A CNC lathe (CNC turning machine) is a machine that spins material around a central spindle and a fixed cutting tool. Instead of being controlled by physical labor, the movement of your components is determined by . Ever wondered how CNC machines seamlessly transform raw materials into precise components? This article breaks down the basics of CNC machine operation, from powering up to navigating the control panels. Discover essential functions like program editing, tool setting, and emergency protocols.What is a CNC lathe? A machine tool used for precise turning and shaping. CNC lathe applications: Aerospace, automotive, medical, and more. Advantages: High precision, automation, reduced manual effort. CNC lathes evolved from manually operated lathes.

CNC (Computer Numerical Control) lathe machines have revolutionized the manufacturing industry by bringing automation and precision to the production of cylindrical parts. These machines use computer programming to control the movement and operation of the lathe, allowing for highly accurate and efficient machining.Operated with Computer Numerical Control (CNC) systems and provided with precise design instructions, CNC Lathes are machine tools where the material or part is clamped and rotated by the main spindle, while the cutting tool that work on . With a CNC lathe, the tooling operates according to a program written and uploaded to the machine, allowing for highly precise and repeatable production. How does a CNC lathe work? Read on to learn the answer — as well as some tips for operation in the process. What are the different operations that can be performed on a lathe machine? Here we’ll go through the types of the basic machining processes on a CNC lathe.

gas and electric meter box locations

The primary CNC lathe machine operations are: Cutting involves separating large amounts of material from a workpiece with a sharp-edged cutting tool. Deformation involves physically changing the shape of a workpiece by removing material from it.Each of these components plays a crucial role in the operation of a CNC lathe machine, working together to produce high-quality, precision-machined parts. Next, we’ll explore the various types of CNC lathe machines and how they differ in terms of capabilities and applications. Lathe machine operations are turning operation, facing operation, taper turning operation, knurling operation, grooving operation with PDF.

What is CNC lathe Machine? A CNC lathe (CNC turning machine) is a machine that spins material around a central spindle and a fixed cutting tool. Instead of being controlled by physical labor, the movement of your components is determined by . Ever wondered how CNC machines seamlessly transform raw materials into precise components? This article breaks down the basics of CNC machine operation, from powering up to navigating the control panels. Discover essential functions like program editing, tool setting, and emergency protocols.What is a CNC lathe? A machine tool used for precise turning and shaping. CNC lathe applications: Aerospace, automotive, medical, and more. Advantages: High precision, automation, reduced manual effort. CNC lathes evolved from manually operated lathes.

CNC (Computer Numerical Control) lathe machines have revolutionized the manufacturing industry by bringing automation and precision to the production of cylindrical parts. These machines use computer programming to control the movement and operation of the lathe, allowing for highly accurate and efficient machining.

Operated with Computer Numerical Control (CNC) systems and provided with precise design instructions, CNC Lathes are machine tools where the material or part is clamped and rotated by the main spindle, while the cutting tool that work on .

turning operations on lathe machine

parts of cnc lathe machine

gauge thickness chart sheet metal

Handy tool for beading, stiffening and offsetting of sheet metal; Four roller stops for easier guidance on straight sheet metal strips; Quick and easy removal of two roller stops for working on curves; Adjustable throat depth from 0 to 6.5 cm / 0 to 2 1/2" Lower shaft radially adjustable (forming pressure increase)

cnc lathe machine operation|turning operations on lathe machine