cnc lathe machine operations pdf Receiving Your Machine The CNC Lathe is designed to give you years of safe service. Read this owner’s manual in its entirety before assembly or use. The advantage of the CNC machine is . Triangle Metal Fabricators | 87 followers on LinkedIn. Custom Metal Fabrication Stainless Steel, Aluminum, Bronze, Copper, Steel, Titanium. New Fiber Laser!

0 · turning operations on lathe machine

1 · turning operation lathe

2 · turning lathe diagram

3 · cnc turning lathe machine

4 · cnc lathe setup

5 · cnc lathe machine operations

6 · basic turning operations

7 · application of cnc lathe machine

$62.70

electric metre box covers

In order to operate and program a CNC controlled machine, a basic understanding of machining practices and a working knowledge of math is necessary. It is also important to become .Computer Numerical Control (CNC) mills and lathes. This course bridges the gap between what persons with a technical education know and what they must learn to begin using machine .

Receiving Your Machine The CNC Lathe is designed to give you years of safe service. Read this owner’s manual in its entirety before assembly or use. The advantage of the CNC machine is .In order to operate and program a CNC controlled machine, a basic understanding of machining practices and a working knowledge of math is necessary. It is also important to become .For a CNC lathe, coordinate axes X and Z are set on the machine and their intersecting point is called a “program reference point”. The X axis assumes a spindle center line to be a position .Only authorized and trained individuals may operate CNC equipment. Code examples shown are for illustration purposes only, and are not meant for operation or programming actual .

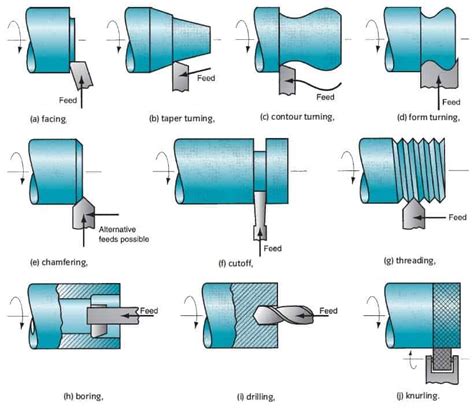

electric meter panel box

CNC Lathe Programming Setup & Operations. Machine Configuration Machine Selection. Cutter Radius Compensation Developing and Interpret Setup Sheets. Fixture Offsets Motion .View and download Cnc lathe manuals for free. H6D-T instructions manual.To operate and program a CNC machine, a basic understanding of machining practices and math are necessary. It is also important to be familiar with the machine control and the placement of the keys, switches, displays, etc., that are pertinent to the operation of the machine. Lathe machine operations are turning operation, facing operation, taper turning operation, knurling operation, grooving operation with PDF.

In order to operate and program a CNC controlled machine, a basic understanding of machining practices and a working knowledge of math is necessary. It is also important to become familiar with the control console and the placement of the keys, switches, displays, etc., that are pertinent to the operation of the machine.Computer Numerical Control (CNC) mills and lathes. This course bridges the gap between what persons with a technical education know and what they must learn to begin using machine toolsCNC.

Receiving Your Machine The CNC Lathe is designed to give you years of safe service. Read this owner’s manual in its entirety before assembly or use. The advantage of the CNC machine is that it can, in most cases, fully machine the complete job .In order to operate and program a CNC controlled machine, a basic understanding of machining practices and a working knowledge of math is necessary. It is also important to become familiar with the control console and the placement of the keys, switches, displays, etc., that are pertinent to the operation of the machine.For a CNC lathe, coordinate axes X and Z are set on the machine and their intersecting point is called a “program reference point”. The X axis assumes a spindle center line to be a position of “XO”, and the Z axis assumes a workpiece finish end face .Only authorized and trained individuals may operate CNC equipment. Code examples shown are for illustration purposes only, and are not meant for operation or programming actual equipment. They may be incomplete or contain errors. Always abide by shop safety instructions and never engage in horseplay.

CNC Lathe Programming Setup & Operations. Machine Configuration Machine Selection. Cutter Radius Compensation Developing and Interpret Setup Sheets. Fixture Offsets Motion Commands. Plotting Coordinates Boring Soft Jaws or Collet. Machine Controls Mounting Workholding Devices. Blood Born Pathogen Fire Prevention/SuppressionView and download Cnc lathe manuals for free. H6D-T instructions manual.

To operate and program a CNC machine, a basic understanding of machining practices and math are necessary. It is also important to be familiar with the machine control and the placement of the keys, switches, displays, etc., that are pertinent to the operation of the machine.

Lathe machine operations are turning operation, facing operation, taper turning operation, knurling operation, grooving operation with PDF.In order to operate and program a CNC controlled machine, a basic understanding of machining practices and a working knowledge of math is necessary. It is also important to become familiar with the control console and the placement of the keys, switches, displays, etc., that are pertinent to the operation of the machine.Computer Numerical Control (CNC) mills and lathes. This course bridges the gap between what persons with a technical education know and what they must learn to begin using machine toolsCNC.Receiving Your Machine The CNC Lathe is designed to give you years of safe service. Read this owner’s manual in its entirety before assembly or use. The advantage of the CNC machine is that it can, in most cases, fully machine the complete job .

In order to operate and program a CNC controlled machine, a basic understanding of machining practices and a working knowledge of math is necessary. It is also important to become familiar with the control console and the placement of the keys, switches, displays, etc., that are pertinent to the operation of the machine.For a CNC lathe, coordinate axes X and Z are set on the machine and their intersecting point is called a “program reference point”. The X axis assumes a spindle center line to be a position of “XO”, and the Z axis assumes a workpiece finish end face .Only authorized and trained individuals may operate CNC equipment. Code examples shown are for illustration purposes only, and are not meant for operation or programming actual equipment. They may be incomplete or contain errors. Always abide by shop safety instructions and never engage in horseplay.

CNC Lathe Programming Setup & Operations. Machine Configuration Machine Selection. Cutter Radius Compensation Developing and Interpret Setup Sheets. Fixture Offsets Motion Commands. Plotting Coordinates Boring Soft Jaws or Collet. Machine Controls Mounting Workholding Devices. Blood Born Pathogen Fire Prevention/Suppression

turning operations on lathe machine

turning operation lathe

turning lathe diagram

Shampoo Bowl Mounting Brackets. Electric Medical Multi-Use Beds Massage & Facial Exam-Treatment & Procedure Tables Pedestal Lift Beds

cnc lathe machine operations pdf|cnc lathe setup