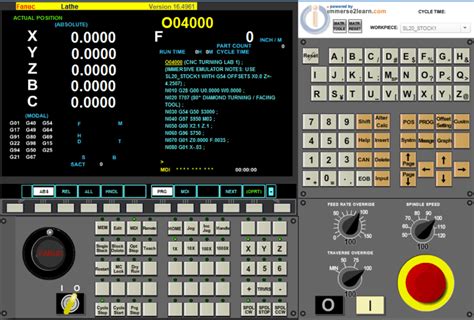

cnc lathe machine fanuc control FANUC has CNC solutions to support your laser machines! The 0 i -LF Plus control .

CNC machines can produce high-quality engine components that can significantly enhance the performance of vehicles. With precise milling and drilling capabilities, these machines can create custom-made parts such as intake manifolds, cylinder heads, and camshafts.

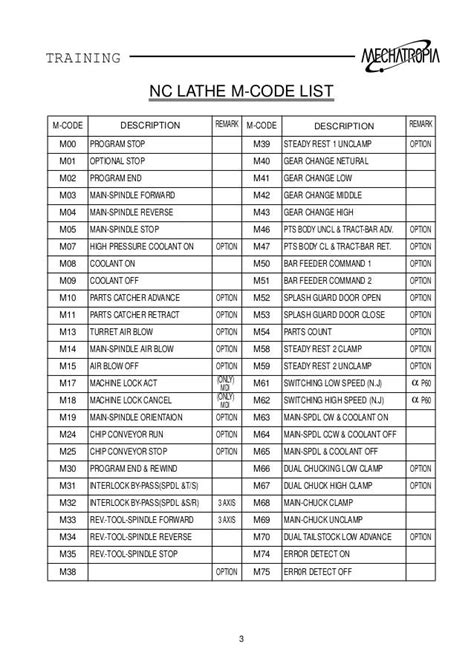

0 · cnc lathe m code list

1 · FANUC open cnc

2 · FANUC lathe m code list

3 · FANUC lathe code

4 · FANUC g code list lathe

5 · FANUC cnc g code list

6 · FANUC cnc controller list

7 · FANUC circular interpolation examples

Haas Automation is the largest machine tool builder in the western world, manufacturing a complete line of CNC vertical machining centers, horizontal. Take a look today. GM-2-5AX Haas Gantry Series 2019

FANUC develops cutting edge CNC and motion control systems for a wide range of applications - From basic high-volume, high-repetition commodity production, to unique, highly complex .FANUC provides industrial PCs for various purposes. Designed with the latest PC .Explore FANUC's CNC software solutions to help improve CNC machine .FANUC works closely with all CAD/CAM manufacturers to make sure you can get .

CNC Retrofits: Extend the lifespan of your machine tools with a new FANUC .FANUC has CNC solutions to support your laser machines! The 0 i -LF Plus control .The FANUC Digital Servo Adapter-MODEL B is a motion control device that enables . In this blog post, an experienced mechanical engineer shares insider tips and techniques for mastering Fanuc CNC lathe commands. Discover how to optimize your CNC programming skills, boost productivity, and take .

FANUC has CNC solutions to support your laser machines! The 0 i -LF Plus control is perfect for flat material processing. If you have more complicated applications, the 31 i -LB Plus and 30 i .CNC, or computer numerical control, lathes or turning machines utilize programmed computer software to automate the control, movement and precision of the turning process. CNC lathes are used in many manufacturing industries, .Find the right CNC controls, drives and accessories for your application and industry here. Offering the next level in speed and precision, FANUC SCARA robots are ideally suited to .

CNC programming exercise for cnc lathe machinists who work on Fanuc cnc control (or similar cnc control). This cnc programming exercise use Fanuc G71 Turning Cycle Fanuc G74 Peck Drilling.Only FANUC offers you the freedom to choose from two versions of CNC control. With the space-saving LCD mounted model and the highly flexible standalone version available, you can . This article is about the Workshift on a CNC Lathe with a Fanuc control. As a beginner one of the first things you will need to learn is how to set the workshift. The workshift is an adjustable figure that tells the control where .

CNC machines work by following the commands or instructions (G-codes / M-codes) which are given in Part Program. Here are G-codes for Fanuc cnc control which are necessary for a cnc machinists to learn to understand . On FANUC CNC machines, the Absolute, Relative, and Machine display screens provide different views of the machine's positional data. These screens are used by operators .FANUC develops cutting edge CNC and motion control systems for a wide range of applications - From basic high-volume, high-repetition commodity production, to unique, highly complex parts that require the highest precision and advanced machining techniques. In this blog post, an experienced mechanical engineer shares insider tips and techniques for mastering Fanuc CNC lathe commands. Discover how to optimize your CNC programming skills, boost productivity, and take your machining projects to the next level.

cnc lathe m code list

FANUC has CNC solutions to support your laser machines! The 0 i -LF Plus control is perfect for flat material processing. If you have more complicated applications, the 31 i -LB Plus and 30 i -LB Plus controls provide 5-axis laser cutting capabilities.CNC, or computer numerical control, lathes or turning machines utilize programmed computer software to automate the control, movement and precision of the turning process. CNC lathes are used in many manufacturing industries, including aerospace, automotive, construction and medical devices.Find the right CNC controls, drives and accessories for your application and industry here. Offering the next level in speed and precision, FANUC SCARA robots are ideally suited to assembly, pick and place, inspection and packaging applications.CNC programming exercise for cnc lathe machinists who work on Fanuc cnc control (or similar cnc control). This cnc programming exercise use Fanuc G71 Turning Cycle Fanuc G74 Peck Drilling.

Only FANUC offers you the freedom to choose from two versions of CNC control. With the space-saving LCD mounted model and the highly flexible standalone version available, you can always be sure to benefit from maximum versatility when it comes to machine design.

This article is about the Workshift on a CNC Lathe with a Fanuc control. As a beginner one of the first things you will need to learn is how to set the workshift. The workshift is an adjustable figure that tells the control where the work zero is.

CNC machines work by following the commands or instructions (G-codes / M-codes) which are given in Part Program. Here are G-codes for Fanuc cnc control which are necessary for a cnc machinists to learn to understand cnc programming.

petsmart electric litter box

FANUC open cnc

What is 3-Axis CNC Machining? A 3-axis CNC machine is the most basic type of CNC machine, moving the tool or part along three primary axes: X, Y, and Z. This type of machining is commonly used for simple and flat geometries. Understanding Each Axis and How It Works. X-Axis: Moves the tool left and right. Y-Axis: Moves the tool forward and backward.

cnc lathe machine fanuc control|FANUC cnc controller list