mig welder settings for sheet metal Still, it’s possible to weld thin sheet metal using the MIG (GMAW), TIG (GTAW), and stick (SMAW) processes. But MIG and TIG provide the best results. This article will teach you how to weld thin gauge metal using each arc . We used to pretty much only use hex head #10 or #12 screws for boxes and whatnot. Lately we started using phillips "truss head" #8 screws for mounting boxes and clips, and they aren't too shabby. They are also 1/2 the cost per fastener, which adds up for the number of screws I go through a year.

0 · mig wire feed settings chart

1 · mig welding wire size chart

2 · mig welding setup chart

3 · mig welding settings chart pdf

4 · mig welding parameter chart

5 · mig welding gas settings chart

6 · mig weld settings chart

7 · basic settings for mig welding

Generally, you’ll need a drill bit that’s the same diameter (in millimetres) as the wall plug, but for accuracy, you can drill a pilot hole using a slightly smaller size drill bit first. What size drill bit for red plugs? Most red wall plugs are 6mm in .

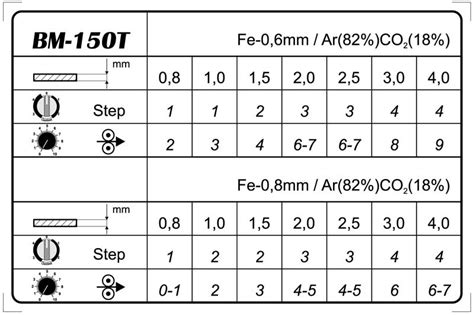

Find below the MIG Welding Sheet Metal Settings Chart which displays the recommended settings for welding different gauge thicknesses of sheet metal. To ensure optimal results, select the appropriate gauge thickness . Mig welding, also known as Gas Metal Arc Welding (GMAW), is a popular method for welding sheet metal due to its speed and versatility. It uses a continuous solid wire electrode .

Still, it’s possible to weld thin sheet metal using the MIG (GMAW), TIG (GTAW), and stick (SMAW) processes. But MIG and TIG provide the best results. This article will teach you how to weld thin gauge metal using each arc . The following basic MIG welding settings are for welding steel with solid wire. Joint design, position and other factors affect results and settings. . In this video I demonstrate how to set up your mig welder so you can weld thin sheet metal. We also showed in this video how to make your pattern, fit and we. In this comprehensive guide, we’ll delve into the intricacies of MIG welding sheet metal and explore the ideal settings for different metal thicknesses. From voltage and wire feed speed to shielding gas selection, we will unravel .

The American Welding Society (AWS) defines it as 3/16 inch or thinner in its AWS D1.3/D1.3M: 2018 Structural Welding Code – Sheet Steel. As when welding other materials, getting the best results with thin materials depends on correct . Preventing burn-through and warping when welding sheet metal is all about controlling the heat. Choose the right welding process and filler metal, and follow these common tips to help ensure success. MIG welding is the easiest arc welding process to master, but the settings on your MIG welder can be a little confusing at first. Incorrect parameters can lead to poor weld quality, lack of penetration, concave welds, undercut, .

To weld sheet metal with solid wires, use electrode positive (EP, or reverse polarity). Don’t attempt to weld thin materials like sheet metal with flux-cored wires, which put more heat into the base metal. TIG welding sheet . To sum it all up, setting up the MIG welder for thin metal welding application is a crucial process and requires utmost attention and precision. Failing to set up the MIG welder properly will lead to potential weld defects. It .MIG welder settings for sheet metal . When MIG welding sheet metal, it is important to set the proper parameters to prevent warping and burn-through or else it will create excess heat and easily blowholes on the metal. Keep in . The Hobart Handler 140 MIG Welder is my top choice because of its versatility and user friendly interface. It is capable of welding thin sheet metals because of its low minimum amperage range and has a smooth and stable arc. It is ideal for hobby welders that can complete their sheet metal welding job without requiring a high duty cycle.

Today we will be going over some tricks to weld thin gauge sheet metal like body panels while avoiding wrapage. I go over 2 different techniques and several .MIG is one of the best ways to weld 20-gauge sheet metal. MIG welding is one of the simplest to use for welding. It is an arc welding process that where you feed a solid wire electrode through a welding gun. . If you prefer the SCT mode then change the inductance settings of the power source to weld puddle. Right filler material .

With a MIG welder, you can weld galvanized steel with great results if you remove the coating. If you wish to weld over the coating, a MIG welder will provide satisfactory results if you use flux-cored wires. For most projects, typical solid wires are incapable of dealing with the issues caused by the coating. Learn how to MIG weld automotive sheet metal in about 5 minutes or less! I keep it short and to the point in this welding instructional video and show how v. Short, Quick Welds-When welding sheet metal with a MIG welder you do NOT want to try and run one long bead like when you’re welding heavier metal. Sheet metal warps easily and also can burn through easily. When welding a long bead on sheet metal you’ll put excessive heat into the panel and run the risk of the puddle falling through the panel.The welding technique for MIG welding sheet metal is relatively straightforward. To achieve a solid weld bead, you want to keep your weld in a straight line. Weaving is not recommended, as any unnecessary heat can cause distortion. MIG gun should be pointed at a 5-15 degree travel angle, with moderate speed. The everlasting discussion is .

This series includes MIG-230MINI, MIG-230, MIG-280, MIG-280PLUS, MIG-350, MIG-350W, MIG-500, and MIG-500W to fit all your demands of welding either on daily metal fabrication or heavy-industry application. The MIG-230MINI/230 and MIG-280/280PLUS can weld the Aluminum sheet at a thickness of 0.35mm. MIG welding sheet metal can be hard, as there’s a lot of heat involved in the process. The trick is finding a balance between the heat and time spent on it. . The key to MIG welding sheet metal is to run it on the same settings as though you were doing a vertical up weld. However, don’t forget that if your machine is running too cold to . Hi to everyone I'm new to welding end the forum looking for advise I want to by welder mainly for thin sheet metal and bodywork I'm looking at few options can you give your advice and opinion Lincoln Power Mig 180C ; Lincoln Electric Powertec 191c Mig Welder ;Millermatic 180 and Portamig 185.

sealed or ported box for metal

MIG welding settings are determined by the type and thickness of the metal to be welded, the gas, and the electrode or filler wire to be used in the process. You also need to have a properly set-up joint. This article provides all the hints and tips on how to set-up a MIG welder and the things you should consider for great results.

mig wire feed settings chart

Related Reading: mig welding sheet metal settings with Charts. For thin sheet metal welding it can be 30 ampere while for thicker (e.g. 1/8” square groove weld)- it can go up to 220 ampere for example. . Stick .

So, it does take a bit of tweaking to get proper shielding gas coverage with your particular MIG welder. Read more: MIG Welding Stainless Steel – A Beginners Guide. Aluminum. Aluminum conducts heat very . For sheet metal what is the welding current needed. i see some machines with low of 15 amp, 20 amp 30 amp. brokenbiker Member. Messages 10,436 Location . I have never successfully used less than 55 on its mig setting. Most of the time on thin sheet you will be doing stitch or joining up tacks. While sheet metal is primarily a TIG welding job, there are times when it’s handy to have an available MIG welder to fuse sheet metal. The Hobart Handler 140 MIG is the best affordable MIG welder for sheet metal.. It’s one of the highest-quality machines available and comes incredibly low-priced.

screwless junction box cover

That’s where your Lincoln 140 MIG welder settings chart comes in. And it’s not in the manual. You’ll find it on your welding decal. On the inside of your Lincoln 140’s cabinet door. . the type of metal your welding (mild steel or Aluminum) the thickness of metal you are welding; the wire Lincoln Electric recommend you use. Whether it . In this video I show you how to properly set up your welder settings for thin sheet metal welding on automotive car or trucks repairs for beginners.In this v. MIG welders are best recommended for these applications as MIG welding is the most common procedure used by people who make and work with sheet metal. Is it possible to stick weld sheet metal? Yes, you can stick weld sheet metal less than ⅛’’ thick, but you will need the right machine and a good set of welding skills to get the job done.Settings for MIG welding sheet metal(14 gauge) steel? I have been messing around with settings and just want to get some extra input on what you guys do. Thanks! . I actually welded some iron boxes at work a few weeks back that was 11 or 12 to 14 gauge sheet metal. I wasn’t allowed much burn through on the back, just a light sugaring if I .

Plug welding kits include pre-cut blanks in multiple sizes plus a step-style bit for drilling sheet metal. Sheet metal patch – If you lose control of the blow-through altogether, you may need to remove the damaged area entirely and start over. Grind out the damage and cut a patch panel from another piece of sheet metal just large enough to .Select the department you want to search in . 3. Adjust Your Torch Angle. Changing the torch angle when MIG welding goes a long way to preventing burn-throughs. Make sure you adjust the angle to shorten the distance between the tip and the metal, no matter the welding position you work in.This will make the arc more stable, giving you more control over the weld and lessening the chance of burn-through. However, getting the MIG welder’s settings just right is key to a successful weld. For filler metal selection, the electrodes in the ER4xxx and ER5xxx are most suitable for welding auto body panels.

You don't need TIG for sheet metal; you just need the right settings and a lesson—like all of us do. Most auto body shops don't use TIG for panels; they use MIG, and that says a lot. Your machine can work fine, with a few operator tricks. The biggest mistakes with sheet metal welding are gap and heat. Flux core is way harder to do on thin metal.

mig welding wire size chart

Metal box, fireproof, waterproof, installed in the tail of the plane. The tail does already survive the majority of impacts. You can’t crash tail first AND going fast. The plane even if loses control entirely, flies like a dart, and crashes nose first.

mig welder settings for sheet metal|mig welding parameter chart