aluminium sheet metal grades We have compiled a short breakdown of each of the grades’ properties in order to provide you with a brief understanding of their many uses. Alloy 1100: This grade is commercially pure aluminum. It is soft and ductile and has excellent workability, making it ideal for applications with difficult forming. A junction box provides a code-approved place to house wire connections, whether for outlets, switches, or splices. Here's how to install one.

0 · strongest type of aluminum

1 · standard aluminium sheet grade

2 · high strength aluminium alloy grades

3 · grades of aluminium explained

4 · aluminum plate grades and strengths

5 · aluminum grades and their uses

6 · aluminium material grade chart

7 · aluminium grades comparison chart

Vanguard Custom Metals is located at 519 N Hydraulic Ave in Wichita, Kansas 67214. Vanguard Custom Metals can be contacted via phone at 316-910-4826 for pricing, hours and directions. .

strongest type of aluminum

The choice of aluminum grade depends on your intended use for the sheet metal. Consider factors such as strength-to-weight ratio, formability, . We have compiled a short breakdown of each of the grades’ properties in order to provide you with a brief understanding of their many uses. Alloy 1100: This grade is commercially pure aluminum. It is soft and ductile .

standard aluminium sheet grade

The choice of aluminum grade depends on your intended use for the sheet metal. Consider factors such as strength-to-weight ratio, formability, machining requirements, weldability, rust resistance, heat treatability, and availability to .

We have compiled a short breakdown of each of the grades’ properties in order to provide you with a brief understanding of their many uses. Alloy 1100: This grade is commercially pure aluminum. It is soft and ductile and has excellent workability, making it ideal for applications with difficult forming.

Aluminum comes in three basic types: 1100, 3003, and 6061. The grade of the aluminum will determine the end-use application and price point. For example, 1100 is a lower-cost material than 6061 but cannot be used for high .

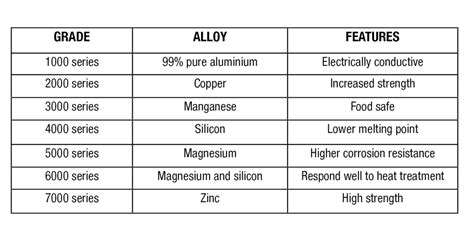

The following article will cover the different grades of aluminium available, their physical and mechanical properties, and some of their most common uses. When working with aluminium there are currently eight series of grades used to categorise the different types of alloy available.

The aluminum grade designations and compositional limits can be found in the Aluminum Teal Sheets (www.aluminum.org/sites/default/files/TEAL_1_OL_2015.pdf). A letter, representing temper, follows the first four digits to indicate if the material is supplied already work-hardened (H) or heat-treated (T), or annealed (O) at the mill. It comes in a range of grades, each tailored for specific uses and scenarios. Aluminum grades vary in terms of strength, corrosion resistance, and other unique properties. Here are some of the most notable ones: 3003 aluminum is like the dependable workhorse of the aluminum world.

Grade 1050 is the most common grade of aluminium sheet available in the UK. Grade 1050 aluminium has the lowest strength of all the commercial grades of aluminium.

high strength aluminium alloy grades

Aluminum sheet metal grades identify alloy families and the metal’s composition. These grades include four numbers followed by a letter. When you look at an aluminum sheet metal grade, the first digit refers to the metal family or series. Unless you’re an expert in metals, you probably need aluminium grades explained in simple terms. In this short guide, we’ll cover everything you need to know to make the right choice, from the different grade series to their applications.This guide aims to shed light on the intricate world of aluminium grades. Each grade of aluminium offers a unique set of characteristics tailored to specific applications, and understanding these variations is key to optimizing its use. The choice of aluminum grade depends on your intended use for the sheet metal. Consider factors such as strength-to-weight ratio, formability, machining requirements, weldability, rust resistance, heat treatability, and availability to .

We have compiled a short breakdown of each of the grades’ properties in order to provide you with a brief understanding of their many uses. Alloy 1100: This grade is commercially pure aluminum. It is soft and ductile and has excellent workability, making it ideal for applications with difficult forming. Aluminum comes in three basic types: 1100, 3003, and 6061. The grade of the aluminum will determine the end-use application and price point. For example, 1100 is a lower-cost material than 6061 but cannot be used for high .The following article will cover the different grades of aluminium available, their physical and mechanical properties, and some of their most common uses. When working with aluminium there are currently eight series of grades used to categorise the different types of alloy available.

The aluminum grade designations and compositional limits can be found in the Aluminum Teal Sheets (www.aluminum.org/sites/default/files/TEAL_1_OL_2015.pdf). A letter, representing temper, follows the first four digits to indicate if the material is supplied already work-hardened (H) or heat-treated (T), or annealed (O) at the mill.

It comes in a range of grades, each tailored for specific uses and scenarios. Aluminum grades vary in terms of strength, corrosion resistance, and other unique properties. Here are some of the most notable ones: 3003 aluminum is like the dependable workhorse of the aluminum world.

Grade 1050 is the most common grade of aluminium sheet available in the UK. Grade 1050 aluminium has the lowest strength of all the commercial grades of aluminium.Aluminum sheet metal grades identify alloy families and the metal’s composition. These grades include four numbers followed by a letter. When you look at an aluminum sheet metal grade, the first digit refers to the metal family or series. Unless you’re an expert in metals, you probably need aluminium grades explained in simple terms. In this short guide, we’ll cover everything you need to know to make the right choice, from the different grade series to their applications.

how to build a sheet metal bending brake

grades of aluminium explained

aluminum plate grades and strengths

aluminum grades and their uses

It's not just a binary detector; the more metal that is placed inside the detector, the larger the secondary field becomes. The detection threshold is then calibrated so that things like zippers and metal buttons aren't enough to set off the detector, but larger metal items will.

aluminium sheet metal grades|strongest type of aluminum