sheet metal design book pdf Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and/ or bending. 3D CAD files are converted into machine code, which controls a .

Quality control is essential to custom metal fabrication shops in order to ensure customer satisfaction and the production of custom metal products to the highest standards. Historically, when quality control issues begin to arise, the custom metal .

0 · sheet metal stamping process pdf

1 · sheet metal material list pdf

2 · sheet metal manual pdf

3 · sheet metal handbook pdf

4 · sheet metal fabrication handbook pdf

5 · sheet metal drawing pdf download

6 · sheet metal design handbook pdf

7 · sheet metal calculations pdf

Use plastic boxes when: There are non-metallic (NM) cables leading in or out of the box. Metal-sheathed wiring relies on bonding with the metal electric box for grounding and should not be used in plastic boxes.

DESIGN TIPS • To ensure cost-effective production, design cut and bend reliefs with a minimum of 2.5x material thickness. • For prototype and short-run quantities, the minimum cut relief can .Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a .Objectives. By the end of today you should be able to. .describe different forming processes, when they might be used, and compare their production rates, costs and environmental .

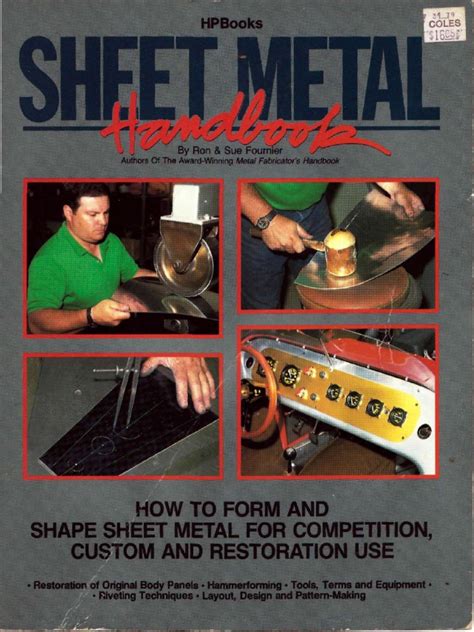

"How to form and shape sheet metal for competition, custom, and restoration use"--Cover Includes index

Ask the publishers to restore access to 500,000+ books. An icon used to represent a menu that can be toggled by interacting with this icon. . sheet-metal-handbook Identifier-ark ark:/13960/t5bd3qk96 Ocr ABBYY .Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and/ or bending. 3D CAD files are converted into machine code, which controls a . Pattern design and proper sheet metal selection

Continuing our focus on sheet metal forming, this issue of DFM guidebook focuses on design guidelines for bend relief parameters, distance between holes and bends and offset bend . Sheet Metal fabrication is the building of metal structures by cutting, bending, and assembling processes. It is a value added process that involves the construction of machines .Understanding the fundamentals of sheet metal fabrication ; The properties of sheet metal materials including aluminum, stainless steel, cold-rolled steel, and beryllium copper; The forming basics, cutting methods, and springback management of sheet metal ; Design guidelines for curls, hems, holes, slots and moreI'm starting a new job pretty soon where I will be designing a lot more parts out of sheet metal. I was just wondering if there are any good reference books out there similar to the Black Book series, but for sheet metal design with all the most useful equations, tables of minimum bend radii, guides for relief cuts, etc.

Recommended for: Beginner & Advanced Sheet Metal Workers Professional Sheet Metal Fabrication is another successful book by Ed Barr. This is the bestselling predecessor to Sheet Metal Shaping, where the author .

sheet metal stamping process pdf

Ask the publishers to restore access to 500,000+ books. An icon used to represent a menu that can be toggled by interacting with this icon. . Vukota Sheet Metal Forming Processes And Die Design Industrial Press, Inc ( 2004) . PDF download. download 1 file . SINGLE PAGE PROCESSED JP2 ZIP download. download 1 file . Sheet Metal fabrication is the building of metal structures by cutting, bending, and assembling processes. It is a value added process that involves the construction of machines and structures from various raw materials. This guide will help you to understand sheet metal product design tips and fabrication techniques. Metal. Metalworking

reproducing sheet metal parts with 3d printing

If you design sheet metal parts, you may know that bend relief is a notch cut made into the . Continuing our focus on sheet metal forming, this issue of DFM guidebook focuses on design guidelines for bend relief parameters, distance between holes and bends and offset bend material when a bend is made close to an edge. .SHEET METAL CAD EXERCISES - Free download as PDF File (.pdf), Text File (.txt) or read online for free. The document lists 40 sheet metal CAD exercises numbered from 1 to 40 without providing any details about the content or objectives of each individual exercise. The exercises are presented in a list format without paragraphs or descriptions.The document provides guidelines for body-in-white (BIW) design and manufacturing. It discusses panel design considerations such as material thickness, stretching, and part splitting to maximize material utilization. Panel joinery guidelines recommend spot welds be loaded in shear and have a total material stack of 4-4.5mm. The BIW manufacturing process involves pressing panels, .

Download PDF - Sheet Metal Forming Processes And Die Design [PDF] [ce6pah57mpo0]. By an engineer with decades of practical manufacturing experience, this book is a complete modern guide to sheet metal f.Defining the Sheet Metal Parameters This task shows you how to configure the sheet metal parameters. 1. Click the Sheet Metal Parameters icon . The Sheet Metal Parameters dialog box is displayed. 2. Enter 1mm in the Thickness field. 3. Enter 5mm in the Default Bend Radius field. 4. Select the Bend Extremities tab. 1. Selection of Sheet Metal Materials. Sheet metal materials are the most commonly used materials in the structural design of communication products. Understanding the comprehensive performance of materials and the correct material selection have an important impact on product cost, product performance, product quality, and processability.. Selection .

sheet metal material list pdf

SOLIDWORKS Sheet Metal Design 2021 textbook has been designed for instructor-led courses as well as self-paced learning. It is intended to help engineers and designers interested in learning SOLIDWORKS for creating real-world sheet metal components. This textbook is a great help for SOLIDWORKS users new to sheet metal design. It consists of total 132 pages covering the .geometries, the user has the option to use non-sheet metal feature tools and then use the Insert Bends or “Convert to Sheet Metal” features. When designing with sheet metal, it is important to think about the best approach to model or design a part. At times, it may appear quicker to use non-sheet metal features (boss-extrude,

Short Desciption: This "Sheet Metal Work by Dr Marcus Bowman" book is available in PDF Formate. Downlod free this book, Learn from this free book and enhance your skills . SOLIDWORKS Sheet Metal Design 2022 for Beginners and Intermediate Users [CADArtifex, Willis, John, Dogra, Sandeep] on Amazon.com. *FREE* shipping on qualifying offers. . Technical support for the book by contacting [email protected]; Read more Report an issue with this product or seller. Previous slide of product details. ISBN-13. 979 .

These are just a few of the many tips and techniques shared by master metal craftsman Ron Fournier. Author of HP's award-winning Metal Fabricator's Handbook, Fournier packs decades of experience designing and shaping sheet metal components for Indy cars, drag race cars, road racers, street rods and street machines into 144 pages.

Ask the publishers to restore access to 500,000+ books. An icon used to represent a menu that can be toggled by interacting with this icon. . Sheet Metal Forming Processes And Die Design, by Vukota Boljanovic . PDF download. download 1 file . SINGLE PAGE PROCESSED JP2 ZIP download. download 1 file .The book gives a systematic and detailed description of a new integrated product and process development approach for sheet metal manufacturing. Special attention is given to manufacturing that unites multidisciplinary competences of product design, material science, and production engineering, as well as mathematical optimization and computer .

There are several ways designers can cut or form the sheet metal into the final part. Manufacturers should take several factors into consideration when designing sheet metal components to ensure an efficient end product. Read the guide below to learn the best DFM tips for sheet metal fabrication. Top 10 Design Considerations for Volume 14B on sheet forming is the second of two volumes on metalworking technology. This volume addresses all methods of sheet metal fabrication technologies, selection of equipment and die materials, specification of forming practices for specific alloys, and new techniques for process design and control.

Source: www.pinterest.ca I want to practice please. Sheet metal 2d drawings for practice pdf 2012 solidworks help dxf/dwg files (*.dxf *.dwg files) another area where we can practice our cad skills is to draw the neutral axis on a side view of the drawing and use the list function to retrieve the length of the components of the sheet metal allowance.

sheet metal manual pdf

Cover title: Sheet-metal worker. Addeddate 2015-02-18 20:44:41.802592 Call number 9925687130001551 Ask the publishers to restore access to 500,000+ books. An icon used to represent a menu that can be toggled by interacting with this icon. . 08-Sheet Metal Work.pdf download. 54.4M . 09-Soldering . 19-Spring Design Manufacture.pdf download. 20.3M . 20-Metalwork .

The first edition of this book was published a decade ago; the Preface stated the objective in the following way. In this book, the theory of engineering plasticity is applied to the elements of common sheet metal forming processes. Bending, stretching and drawing of simple shapes are analysed, as are certain processes for forming thin-walled .SolidWorks Sheet Metal Design Presentation Author: Natarajan Ramamoorthy Subject: Sheet Metal Design and Development Keywords: SolidWorks, Sheet Metal Design, Progressive Design, Migrate from Autodesk Inventor Created Date: 5/4/2014 7:40:12 PM

Sheet Metal, Top Down Design, Weldments, Surfacing and Molds Alejandro Reyes MSME, CSWE, CSWI ® SDC PUBLICATIONS www.SDCpublications.com Better Textbooks. Lower Prices. Visit the following websites to learn more about this book: Powered by TCPDF (www.tcpdf.org) Beginner's Guide to SOLIDWORKS 2021 – Level II

replace socket with junction box

residential metal deck railing fabricators

Equipment• Enswell, sometimes called end-swell, endswell, stop-swell, no-swell or eye iron, is a small piece of metal with a handle. It is traditionally kept on ice and is used to cool the area of a bruise or a cut by applying direct pressure to See more

sheet metal design book pdf|sheet metal calculations pdf