cnc machine parameters pdf This course emphasizes anapproach to CNC machining referred to as ubtractive RapidS Prototyping (SRP). SRP deals with small quantities of functional prototypes. Functional . Advantages of the precision sheet metal jobs were indoors, you have your own bench and tools, no need to travel to job sites or climb up ladders etc. Plus its very hard to learn, and keeps out excess workers.The distribution box is a small box that comes after the septic tank but before the drain field. They're usually made of either plastic or concrete, and they have several openings on different sides where the drain field lines .

0 · types of machining PDF

1 · thermal machining PDF

2 · siemens parameter manual machine data

3 · siemens parameter manual PDF

4 · modern cnc machining guide

5 · modern cnc machining

6 · machining processes and machines PDF

7 · cnc machining guide PDF

Sheet metal gauge determines the thickness and strength of HVAC ductwork, impacting its ability to withstand pressure and airflow. Choosing the right thickness is crucial for ensuring compliance with safety regulations and meeting minimum requirements set by codes.

The ultimate CNC machining guide Choosing the right type of CNC machining When selecting a manufacturing process for your part, you’ll need to evaluate if it’s a better fit for 3-axis or 5-axis .

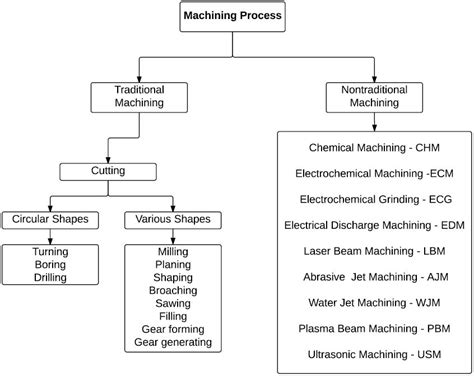

Machining is one of the eight basic manufacturing processes. This textbook covers the fundamentals and engineering analysis of both conventional and advanced/non-traditional .CUTTING PARAMETERS - GETTING STARTED REFERENCE GUIDE LANGMUIR SYSTEMS MR-1 CNC MILLING MACHINE (REV. 11/21/2022) NON-FERROUS MATERIAL Feed Rate .CNC Machining is often the last step in metal manufacturing, or sometimes the only process involved. Compared to other metalworking techniques, CNC machining is capable of meeting .

This course emphasizes anapproach to CNC machining referred to as ubtractive RapidS Prototyping (SRP). SRP deals with small quantities of functional prototypes. Functional .

Types of CNC Milling Machines • Two classes of machining centers: • Vertical spindle and horizontal spindle • Types of milling machines: vertical and horizontal machining centers (VMC .In this article, we will delve deep into the essential CNC machine parameters and provide a downloadable PDF guide to assist both beginners and experienced operators in optimizing .In a CNC Machine functions and slide movements are controlled by motors using computer programs. Conventionally, a human operator decides and adjusts various machines .

program modern CNC machine. is the simpler of the two methods. In effect, this is a macro programming language used to instruct the machine to perform pre-programmed cycles (i.e. .machine data is, for example, addressed by means of this identifier (with an additional label) for programming in the part program. This identifier is displayed in the data lists on the user interface of the control.

The ultimate CNC machining guide Choosing the right type of CNC machining When selecting a manufacturing process for your part, you’ll need to evaluate if it’s a better fit for 3-axis or 5-axis machining. Generally, parts with simpler designs can be made quickly and affordably using 3-axis machines, while 5-axis

Machining is one of the eight basic manufacturing processes. This textbook covers the fundamentals and engineering analysis of both conventional and advanced/non-traditional material removal.CUTTING PARAMETERS - GETTING STARTED REFERENCE GUIDE LANGMUIR SYSTEMS MR-1 CNC MILLING MACHINE (REV. 11/21/2022) NON-FERROUS MATERIAL Feed Rate (Inches Includes: Aluminum, Brass, Bronze, Copper, Plastics Excludes: Titanium Alloys Cutting Tool Size Cutting Tool Spec. (Recommended) Spindle Speed (RPM) Cutting Direction Width .CNC Machining is often the last step in metal manufacturing, or sometimes the only process involved. Compared to other metalworking techniques, CNC machining is capable of meeting the tightest tolerances, and producing the most accurate, precise products with a .This course emphasizes anapproach to CNC machining referred to as ubtractive RapidS Prototyping (SRP). SRP deals with small quantities of functional prototypes. Functional prototypes are made from materials like aluminum, steel and polycarbonate that cannot be produced with widely available additive Rapid

Types of CNC Milling Machines • Two classes of machining centers: • Vertical spindle and horizontal spindle • Types of milling machines: vertical and horizontal machining centers (VMC and HMC) • ATC types: carousel-type and swing-arm-type

types of machining PDF

In this article, we will delve deep into the essential CNC machine parameters and provide a downloadable PDF guide to assist both beginners and experienced operators in optimizing their machining processes.

In a CNC Machine functions and slide movements are controlled by motors using computer programs. Conventionally, a human operator decides and adjusts various machines parameters like feed, depth of cut etc depending on type of job, and controls the slide movements by hand. traditionally performed by skilled machinists. consistent part quality.program modern CNC machine. is the simpler of the two methods. In effect, this is a macro programming language used to instruct the machine to perform pre-programmed cycles (i.e. fac. g, drilling holes in arrays, etc.). When writing a conversational program, you simply enter the appropriate parameters .machine data is, for example, addressed by means of this identifier (with an additional label) for programming in the part program. This identifier is displayed in the data lists on the user interface of the control.

The ultimate CNC machining guide Choosing the right type of CNC machining When selecting a manufacturing process for your part, you’ll need to evaluate if it’s a better fit for 3-axis or 5-axis machining. Generally, parts with simpler designs can be made quickly and affordably using 3-axis machines, while 5-axis

Machining is one of the eight basic manufacturing processes. This textbook covers the fundamentals and engineering analysis of both conventional and advanced/non-traditional material removal.CUTTING PARAMETERS - GETTING STARTED REFERENCE GUIDE LANGMUIR SYSTEMS MR-1 CNC MILLING MACHINE (REV. 11/21/2022) NON-FERROUS MATERIAL Feed Rate (Inches Includes: Aluminum, Brass, Bronze, Copper, Plastics Excludes: Titanium Alloys Cutting Tool Size Cutting Tool Spec. (Recommended) Spindle Speed (RPM) Cutting Direction Width .CNC Machining is often the last step in metal manufacturing, or sometimes the only process involved. Compared to other metalworking techniques, CNC machining is capable of meeting the tightest tolerances, and producing the most accurate, precise products with a .This course emphasizes anapproach to CNC machining referred to as ubtractive RapidS Prototyping (SRP). SRP deals with small quantities of functional prototypes. Functional prototypes are made from materials like aluminum, steel and polycarbonate that cannot be produced with widely available additive Rapid

Types of CNC Milling Machines • Two classes of machining centers: • Vertical spindle and horizontal spindle • Types of milling machines: vertical and horizontal machining centers (VMC and HMC) • ATC types: carousel-type and swing-arm-typeIn this article, we will delve deep into the essential CNC machine parameters and provide a downloadable PDF guide to assist both beginners and experienced operators in optimizing their machining processes.In a CNC Machine functions and slide movements are controlled by motors using computer programs. Conventionally, a human operator decides and adjusts various machines parameters like feed, depth of cut etc depending on type of job, and controls the slide movements by hand. traditionally performed by skilled machinists. consistent part quality.

thermal machining PDF

Beads and bends will add stiffness, so you can use thinner metal compared to a mostly flat sheet with little or no support underneath. I used 16 gage flat sheet for a 24" x 43" trunk floor, but have two u-channel supports 12" apart in the center, and two smaller right angle iron pieces to help support the outer 18" or so.

cnc machine parameters pdf|cnc machining guide PDF