sheet metal welding years of word of mouth Now that we’ve covered the essential considerations for different arc welding processes, let’s discuss how to prevent and fix common . See more $23.95

0 · welding sheet metal standards

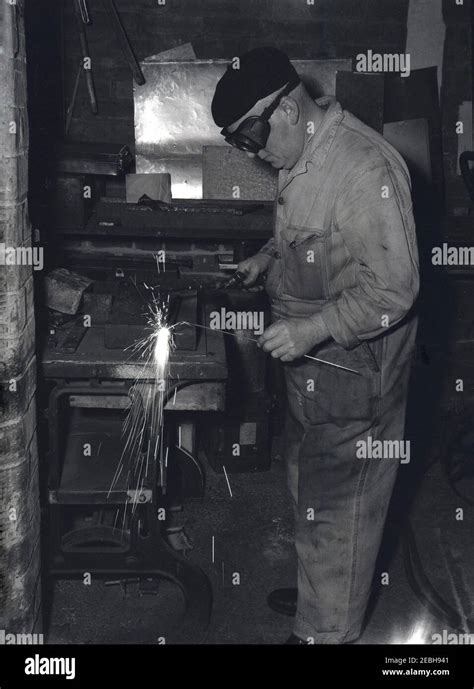

1 · welding sheet metal in the 1950s

2 · welding sheet metal

3 · sheet metal welding process

4 · sheet metal welding guide pdf

5 · intermittent welding sheet metal

6 · history of welding sheet metal

7 · approved sheet metal welding process

$99.90

Each welding process requires specific precautions and equipment setup for a successful sheet metal weld. So, let’s discuss the preparation needed for each arc welding process before proceeding to the common problems with thin gauge welds. See moreNow that we’ve covered the essential considerations for different arc welding processes, let’s discuss how to prevent and fix common . See more

Welding thin metal is challenging. There is no denying that. But, if you practice and use the tips we shared in this article, you’ll get the best chance for success. After you inevitably burn through some scrap sheets of metal and warp others, you’ll gain more experience and learn . See more This became a usable welding process in the late 1800s and early 1900s that still is used today to weld galvanized sheet metal with cupro-bronze filler material. The arc between . Here, we’ll explore the sheet metal welding methods we use in our shop and explain what to expect from each one. Table of Contents. 1 Spot Welding. 1.1 Considerations .

In the engineering sector, word of mouth is a crucial element of the sales and growth of a company.Welding is a crucial process in modern sheet metal fabrication. In short, the process involves fusing metals by heating them to a high temperature, and then the metals solidify in their new . This article provides a detailed view of the various methods used in welding sheet metal, including their advantages and applications. It also provides vital tips to note when .

There are five common welding approaches for sheet metal, including TIG, MIG, Stick, Laser beam & plasma welding. What is the thickness limit for sheet metal welding? O.8 . One of the most commonly used welding techniques in sheet metal manufacturing is MIG (Metal Inert Gas) welding. MIG welding utilizes a wire electrode fed through a welding .In this article, we will explore the key factors to consider when choosing a welding method, discuss surface preparation techniques, provide tips for efficient welding, and highlight the .

266 votes, 174 comments. 439K subscribers in the Welding community. Reddit inc. is selling your content to AI farms. . I have done a good bit of work with sheet metal, I welded utility truck bodies for a couple years. 36 grit 3M .

welding sheet metal standards

SHREE KRISHNA INTERNATIONAL (SKI) established in the year 1999 is an ISO 9001:2015 certified company in the sector of Precision Metal Components, constantly evolving thanks to the contribution of its collaborators and word of mouth from its customers.Best Metal Fabricators in Youngstown, OH - Spartan Fabrication, Garrett's Fabricating, Youngstown Metal Fabricating, Wycked Welding & Fabrication, Iron Worx Welding, Thompson Fabricating, Deans Welding & Fabrication, M.V.G, D2 Mobile Welding and Repair, KilarA reliable and experienced Sheet Metal Worker with 7 years of experience fabricating, installing, and maintaining high- quality sheet metal products. Skilled in reading blueprints, operating metal- working machinery and tools, and performing maintenance and repair work. . Operated sheet metal and welding equipment such as shears, rollers .Source: I have held a myriad of certifications ranging from Aerospace, power generation, high pressure boiler and process piping, offshore oil and gas, structural, sheet metal, and general fabrication certifications. All of which, every single employer certification stayed with the employer

In the same way metal does smell, after you touch it and it reacts with the oils on your skin. The oils are necessary for the smell, but the metal is the unique part. (E.g. wood doesn't smell like that after it comes into contact with your skin) In this case saying metal smell is enough for people to understand what you mean. The Hobart Handler 140 is an excellent choice for sheet metal welding due to its versatility and user-friendliness. With an amperage range of 25 to 140A, it’s capable of handling various thin materials, including sheet metal. . I got really into welding almost 15 years ago. Since then, I've learned various welding processes for business and .

We have been serving Yuma for over 10 years with a crew who has a combined experience of 100 plus years in the iron work and metal building industry. Our projects range from Small to Large and we are a full service contractor but we also work with other local and out of town contractors to ensure you get the best price and product out there.

Basic Sheetmetal and Welding Familiarization. Flashcards; Learn; Test; Match; Q-Chat; Get a hint. What factors determine a quality shop head. . micro word lesson 4. 7 terms. jestjon. Preview. Test 2 Ch 5 . Teacher 76 terms. crebelo16. Preview. LA non fiction unit of study. 18 terms. julianhernandez327.No. Weld is an English word, of Germanic origin. It receives the agent noun -er. If it were a Latin word, it would be correct to use -or. Welder is the correct term, weldor is an archaic term from the 50's when the United Brotherhood of Weldors, Cutters and Helpers of America, a union that felt that their trade needed a little bit more class (citing, for instance, the prior example of "aviator").Which word-of-mouth marketing technique specifically uses the Internet to facilitate the spread of word-of-mouth? . 12. A few years ago a new Cancun Mexico beach resort hired college students on several college campuses to talk about its resort to fellow students and try to spark some positive word-of-mouth. These students are an example of:Most of these jobs are rarely advertised on job boards because they don't want every person fresh out of welding school with a 6G cert applying because 9 times out of 10 they're not going to be ready for welding in the field. These jobs are more word of mouth and you have to network with the right crowd.

The sheet metal fabrication side of company continued to grow in the 1990's and Charles & Randy turned their attention solely to EHC Industries and modernization of the shop floor. With the expansion of EHC came new equipment; the company's first CNC punch, which allowed them to create high quality precision parts and eventually automated laser .Created 1 year ago. Share. Share. Get better grades with Learn. 82% of students achieve A’s after using Learn. . With sharp or rough sheet metal. Which of the following PPE items use synthetic material? . When welding, watching the arc with unprotected eyes can cause _____.Specialties CNC Machining, Laser Cutting, Pipework Installation, Steel Fabrication, Sheet Metal Work, Spiral Welding, Anti-Wear Bends, Chiller Pipework, Material Handling Equipment, CNC Milling .Like so much of metal fabrication, welding is more than just another step in the process. Decisions taken early on with sheet metal welding. will impact on the eventual cost and timing of a project so knowing whether this process is .

Study with Quizlet and memorize flashcards containing terms like ____ is a type of welding. , GMAW and ____ welding are the first choice for many welding fabricators because these processes are cost effective, produce high- quality welds, and are flexible and versatile., Welder _____ are employed in some welding shops to clean slag from the welds and help move and . Sheet metal welding is a process that seems relatively simple at first glance – connecting several metal parts with the help of high temperatures and filler material. . Over the course of the years, the way modular homes are designed and manufactured has changed considerably. The introduction of. Join the Team. [email protected] +372 686 .

Then it branched into repairing equipment for customers and spread by word of mouth. It is not hard but there is a large learning curve to it. . You will need to learn to back purge and welding ss sheet metal without warpage. . Till this year restaurants welding was very good. If do work get cash or get paid the same day. GP Precision Sheet Metal Fabrication, Hackettstown, N.J., operates two laser cutting machines, regularly cutting thicknesses up to 0.1875 in. The company is getting a new fiber laser cutting machine to accompany its 4-kW Cincinnati machine. GP . Meet the Author, Darren O’Brien: founder of Woodward Fab, is a pioneer in metal fabrication with over 50 years of experience.In this blog, he shares his expert knowledge on sheet metal fabrication tools, techniques, and innovations. Join Darren as he provides valuable tips and insights into industry trends from a true veteran of the field.Accredited to BS EN ISO 9001 for the last 20+ years, at the beginning of 2023 Easton Sheet Metal Ltd. made the decision to invest and support the aerospace and defence sectors. We are pleased to announce that, as of 19 th December 2023, ESM have attained a new height in the world of quality and are now also AS 9100 accredited (technically .

Direct Engineering & Site Services Ltd | 3,414 followers on LinkedIn. - FABRICATIONS - SHEET METAL - CNC MACHINING - LASER CUTTING - SITE INSTALLATIONS - SILO MANUFACTURE - CHILLER PIPEWORK .159 By definition, light metals are considered to be metals that have a density of less than 5 g/cucm [3]. Sheet met-al is metal with a thickness of 3.2 mm or less.

Imagine a welding process that minimizes distortion, enhances precision, and improves efficiency. Laser welding technology for sheet metal does exactly that, revolutionizing industries from automotive to high-tech electronics. This article explores the advantages of laser welding over traditional methods, detailing its superior heat control, speed, and flexibility. .As someone who uses metric. Yes. Yes I can. 0.6 and 0.5mm. I can. Since I deal with 0.8 and 0.9mm welding wires regularly. And 0.5-0.4 mm sheet metal. What is your point actually? That 0.1mm is somehow unfathomable difference? There . 4 reviews and 16 photos of VITAL ARC WELDING "Tom Domenico helped us select a welding machine that fit our project needs. . We were recommended by word of mouth and they are absolutely right. Helpful 1. Helpful 2. Thanks 0. Thanks 1. Love this 0. Love this 1. Oh no 0. Oh no 1. Bryan C. Riverside, CA. 6. 31. . Aztec Sheet Metal. 4. Metal .

welding sheet metal in the 1950s

Waterproof IP68 External Junction Box,2-Way Outdoor Cable Connectors with 2 Cable M20 Gland Wire Connector Electrical Junction Box for 4-12 mm Diameter Cable, Black

sheet metal welding years of word of mouth|intermittent welding sheet metal