how to sheet metal We've gotten a lot of question on sheet metal fab over the years. So we decided to do a brief how-to for you guys. If you plan on doing a decent amount of sheet metal fab there are two. Get information, directions, products, services, phone numbers, and reviews on T/A West Creek Sheet Metal in West Creek, undefined Discover more Roofing, Siding, and Sheet Metal Work companies in West Creek on Manta.com

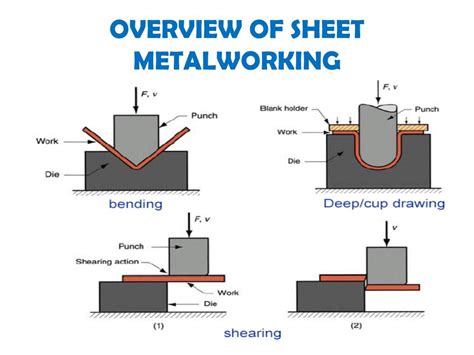

0 · what is sheet metalworking

1 · types of metal sheets

2 · steel sheet price per kg

3 · sheet metal types list

4 · sheet metal types and grades

5 · sheet metal size chart

6 · sheet metal characteristics

7 · metal sheets at screwfix

WELE high speed cutting machines feature state-of-the-art technology and innovative features that improve machining accuracy, enhance surface finish, reduce bur formation and improve chip evacuation.

Ready to tackle your next metalworking project? In this video, we reveal essential techniques for DIY metal cutting, whether you're working with sheet metal,. We've gotten a lot of question on sheet metal fab over the years. So we decided to do a brief how-to for you guys. If you plan on doing a decent amount of sheet metal fab there are two. This complete guide’ll walk you through the basics of sheet metal fabrication and provide all the information you need to get started. From understanding the materials and processes involved to tips on finding the right .

You may need to know how to cut sheet metal while working on DIY craft projects, gutter repair, ductwork, or metal roofing. Sheet metal is made from different materials and .The manufacturing & design guide. Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on .Sheet Metal prepares learners for a career as skilled sheet metal craft professionals with rigorous, industry-designed content. This curriculum covers critical concepts needed in this broad field, including installation of ductwork, .If the metal has been painted previously, remove lose or scaling paint with a dull putty knife. Step #3: Prime the Metal. Prime your metal surface to ensure rust inhibition and effective adhesion of your topcoat. Consider Corotech ® Universal Metal Primer for non-ferrous metals and Corotech ® Alkyd Primers for ferrous metals.

You can mirror sheet metal bodies as well as selected sheet metal features. Use the Right Plane to mirror the edge flange feature. Adding a Tab. Bending a Tab. Now you specify how to bend the tab. Adding a Cut Across a Bend. To cut . Welcome to the Upcycle Design Lab. I like to craft with recycled, repurposed, and unwanted materials. There is a lot of experimenting with trash and recyclab. Today Eric Blesgraeft and Javier Arias show us the proper method of lifting sheet metal so that you dont strain your back or damage the materiel in the proce. Welding holes in thin metal or sheet metal is a crucial skill. Whether you're correcting a mistake or shaving a body so it's perfectly smooth this skill will.

Did you know that TIG welding is the best option for sheet metal? The biggest problem any welder is going to face when it comes to sheet metal is the heat in. Learn how to use a straight handle hand seamer to bend sheet metal.Learn about--Sheet metal gauges-Types of hand seamersSign up for the email list. Grab some.

Introduction. W. i th its sleek, modern look, metal panel roofing was our first choice for the Getaway.It has no visible seams and is maintenance free — even a light rain will wash leaves and sticks off the roof.Even better, it won’t grow moss and algae in the shade of the Wisconsin woods.. A metal roof will reduce cooling costs by reflecting heat and last 50 to 70 . In this video I show how a nibbler works and how to use one. (02:18 Listen to my reaction! 🤣) I had never used a sheet metal nibbler before this! It's an e. Sheet metal is made from different materials and comes in various thicknesses, known as gauges. An easy way to remember sheet metal thickness is that the higher the gauge number, the thinner it is. The thicker the sheet metal, the higher the cost tends to be. Metals such as copper, aluminum, brass, and cold-rolled steel are generally soft, and .

How To: Tip an edge on sheet metal with Hand tools - Fabrication That Doesn't Suck#HomeMadeTools #Fabrication #SheetMetalWorkWanna send me stuff? Email myka.Shop for steel sheet at America's Metal Superstore. Largest selection of Hot Rolled Steel Sheet, Cold Rolled Steel Sheet, Galvanized Steel Sheet at wholesale prices. Any Quantity, Any Size, Delivered Anywhere! Select Size; 1 x 2 Ft. 1 x 4 Ft. 1 x 8 Ft. 2 x 2 Ft. 2 x 4 Ft. 3 x 4 Ft. 4 x 4 Ft. .Sheet Metal Box: This is a great project to make if you are new to working with sheet metal. At this point in my class all of our sheet metal projects have been very simple with, at most, one bend. But, when we get to the this project my students always have a hard.

Welders can struggle with thin sheet metal because the hot arc warps or burns through the metal easily. Even professional welders flounder with welding thin stock at times. Still, it’s possible to weld thin sheet metal using the .

Sheet metal is a very useful material that can be used for a wide variety of applications. With that being said, you will usually need to cut this building material to the right size and shape for your exact project. There are . How to edit a sheet metal rule or create a new one in Fusion. A new thickness value may be desired. Switch rules in an existing design Click the Sheet Metal Rule icon to change the rule in use in the current design. Edit .

SHEET METAL CIRCLE WITH CONTOUR FLANGE

Kwando Technic introduce How to Homemade A Metal Pressing Tool.#sheetmetal; #foldmetal; #pressingtool; #kwandotechnicPlease like, share and subscribe my chan. go to the sheet metal tab, under setup, pick sheet metal defaults, uncheck use thickness from rule, type in the new value. Thaddeus Hosford NUC9i9QNX i9-9980HK, Win 10 Pro 64 TEACHING THE NEXT GENERATIONTUTORIAL RESOURCES━━━━━━━━━━━━━UPDATE: For easy access, I have shared all the Onshape video files in the 'Public' section. If you.

outlaws of thunder junction buy a box promo

Use sheet metal bend parameters like K-factor, bend allowances, and bend deductions, to ensure accurate flat pattern generation for your sheet metal designs. It's crucial for product manufacturability, ensuring precise dimensions and fit, by accounting for material stretch and compression during bending. In this video I show how to set up and tig weld thin metal. There are a lot of different steps to take and I try to make it as easy as possible. From how to . If you've got scrap sheet metal around, you can put it to use in projects to save material costs. Here's a cool trick for bending thin-gauge sheet metal with.

Gas welding sheet metal is a great way to join two pieces together quickly and efficiently without having to rely on traditional methods such as soldering or brazing. With the right tools and know-how, however, anyone can become a master at gas welding sheet metal in no time! Keep these tips in mind as you get started on your next project . A filler is a little piece of metal that is delivered by a welding rod and fills in any gaps between two metal surfaces. When molten metal comes into contact with gas in the air, it forms oxides or nitrates, which can weaken the bond. Flux is a non-metal chemical that prevents this from happening. Welding is a heat-based method of joining metals.Making Dimples in Sheet Metal Without Dimple Dies - Fabrication That Doesn't Suck. Today we look at using what you already have in your shop to make basic d.

what is sheet metalworking

types of metal sheets

Cut your new panel the way you want it, lay it up an draw around it, and then cut the truck out about 1/2 in smaller or whatever your flange width is. Then go around the truck metal with the flange tool and then lay the new panel in and check the fit.

how to sheet metal|what is sheet metalworking