sheet metal parts ideas Sheet metal fabrication is a great manufacturing process for creating long-lasting, durable, precise metal parts and enclosures. Because sheet metal parts are made from flat sheets of metal, different design considerations are necessary .

TRINITY PRO 72" Stainless Steel Rolling Workbench with Adjustable-Height Top Solid 1.5” Thick Butcher Block Top; Top Adjustable Height 0” - 12” Ball Bearing Drawer Slides; Total Weight Capacity 2,200 Lbs

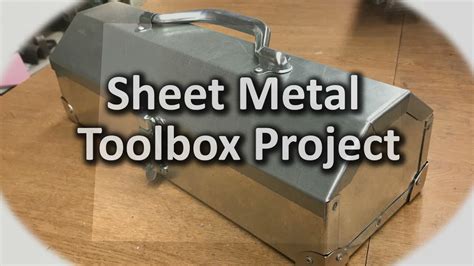

0 · sheet metal projects pdf

1 · sheet metal projects for beginners

2 · sheet metal project ideas

3 · metalwork projects for students

4 · metal projects for students

5 · metal fabrication projects

6 · items made out of metal

7 · free sheet metal project plans

Above: varnished-cloth electrical wire on the ballast used in a fluorescent light fixture in a 1960's home built in northern Minnesota See . See more

Consider material and finishing options along with design elements like bends, reliefs, holes, and slots when designing sheet metal components.

The sheet metal design process involves conceptualizing, drawing, and creating detailed plans for cutting, shaping, and joining metal. It’s all about turning metal sheets into durable, functional, and aesthetic products for various industries, .Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with .

Sheet metal fabrication design guide with tips and best practices on designing sheet metal parts for processing via laser cutting and precision CNC bending.

Favorite. Sheet metal is easy to cut, bend, and form. You can make a ton of different cool stuff with it too! Check out these sheet metal projects to get some ideas. Improved Harbor Freight Metal Bending Brake. by marple200 in .Sheet metal fabrication is a great manufacturing process for creating long-lasting, durable, precise metal parts and enclosures. Because sheet metal parts are made from flat sheets of metal, different design considerations are necessary .Custom sheet metal parts in as little as. 2 days. No minimum quantities. Free shipping. Made in the USA. Upload your STEP, DXF or EPS file for instant pricing! GET started.

When you design sheet metal parts, you face a series of unique challenges Although parts are typically designed in their formed state, they begin as a flat plate or sheet. As a result, manufacturability becomes a critical aspect of every feature making up the finished part. Add to this the need to account for material thickness, along1 Measurement calculated according to VDI3441 on maximum axis lengths. 2 Cutting quality on limit thicknesses may depend on geometries required, material quality and system operating conditions. At limit values, burrs may be present on the lower edge of the cut. These values are for the Salvagnini reference materials. 3 Maximum consumption calculated on a system with .An Inventor® Ideas submission. An Inventor® Ideas submission. For more information, see Part Tab Reference (Application Options). Correct icons for Suppressed Sheet Metal and Weldment parts within assemblies. In the .

Are you interested in starting a metal business but not quite sure which area to focus on? Analysts forecast that the metal and metal manufactured products industry is growing at a CAGR of 5.2% and will reach .5 trillion in the next few years.. Therefore, starting your metal and steel business ideas in 2024 can be a noble idea.. The good news is there are several . Sheet metal fabrication is an ideal process for creating durable parts, from single prototypes to high-volume production runs.. Sheet metal has many commercial applications and can be a cost-effective way to create your parts. However, because sheet metal parts are made from a single, flat sheet, there are additional design considerations compared to other . If you love to do DIY, then this is the right place for you.It is amazing that you can make a DIY metal brake in just 20 ways, as we have discussed. Accent your space with these 20 DIY metal brake ideas.These metal crafts are easy to make and will add character to your room.. If you have never made such metal brakes before, then there is no need to worry.That being said, custom manufactured parts are always going to be more expensive than something you can buy off the shelf. Cost per unit for 3 parts is always going to be higher than for 3000 parts. Also, everyone I know is slammed with work right now.

3. Choosing Materials and Finishing Sheet Metal Parts. These two go together. To start, aluminum (6061-T6 or 5052-H32), steel (CRS1008), and stainless steel (304-2B) are common sheet metals that are always in stock, so you’re less likely to incur a .Sheet metal parts with a minimum of 0.9mm to 20mm in thickness can be manufactured. Hole Diameter. When designing parts for laser cutting one should not make holes smaller than the thickness of the material. Bends. Bends in sheet metal are manufactured using sheet metal brakes. A +/- 1 degree tolerance on all bend angles.

sheet metal projects pdf

Jun 2, 2012 - Explore Paul LeTang's board "Press Brake Parts" on Pinterest. See more ideas about press brake, sheet metal work, sheet metal. The heavy gauge thermoforming process offers key advantages as an upgraded replacement for many parts currently manufactured from metal. Weight reduction is a key advantage – plastic parts are lighter than metal. Further, custom plastic thermoforming can be used to produce complex geometric part shapes that are not possible with sheet metal at a .Discover the art of sheet metal design in this comprehensive guide. Learn fundamental principles, techniques, and prospects. . You may have wondered about the intricate precision engineering that goes into those metal parts used in many industries. . Instead, they use CAD software and its incredible precision to bring ideas to life. 3D and . The sheet metal passes between the rollers, and the pressure shapes the desired bead profile. The bead roller uses a pair of complementary dies to roll a bead or rib into a sheet metal panel Shrinking and Stretching These two techniques used to change the surface area of sheet metal without significantly altering its thickness.

rejilla de metal antideslizante fábrica

Metal Sheet Craft Ideas: Inspiration for Your Next Project . . production company and rapid manufacturer focusing on rapid prototyping and low volume production of plastic and metal parts, has advanced manufacturing technology, one-stop service, diversified manufacturing methods, on-demand manufacturing services and efficient manufacturing .Aug 22, 2016 - sheet metal fabrication products. See more ideas about sheet metal fabrication, metal fabrication, sheet metal.

Jun 28, 2013 - Some examples illustrating A&E's precision craftmanship of sheet metal finished parts and assemblies. See more ideas about sheet metal, metal products, aluminum sheet metal.

reiniciar de fabrica j7 metal sin botones

sheet metal projects for beginners

Sheet metal components business ideas; Automobile sheet metal parts; Sheet metal components; Sheet metal component designing service; Sheet metal components, for industrial; Passenger vehicle automotive stamping parts; Sheet bending job work; Textile machine sheet metal parts, capacity: 1-5 mm; 30. Drawing Sheet metal forming to make cup‑shaped, box‑shaped, or other complex‑curved, hollow‑shaped parts Sheet metal blank is positioned over die cavity and then punch pushes metal into opening Products: beverage cans, ammunition shells, automobile body panels Also known as deep drawing (to distinguish it from wire and bar drawing) ©2007 John . Read: Best Welding Business Ideas. 28. Make Metal Business Cards. At present, there is a big demand for metal business cards all across the globe. There are a wide variety of metal business cards that have gained popularity among customers. They can be of black metal, stainless steel, and gold.

/ Blog / Design Tips to Save Costs: Custom Sheet Metal Parts & Enclosures Design Tips to Save Costs: Custom Sheet Metal Parts & Enclosures. 2021-04-07 Many of our design tips and resources are aimed to help you work within our manufacturing capabilities and make the best decisions for your specific requirements, in order to end up with a result .

Because sheet metal products have a history of being designed by the guy who actually does the work on the floor, sheet metal products (think HVAC ducting, as well as the lockers in your gym) tend to be excellent examples of design for assembly, especially when looking at self-locating parts, which reduce assembly errors.Detailed project report on sheet metal parts/components - Get comprehensive project reports, formulations, startup guides, and expert consultancy for business success - Grow your business, Best startup ideas for students, Entrepreneur opportunities, Onlin Custom laser cut switch panels have applications in dozens of fields including aerospace, automotive, and manufacturing. We also loved getting to machine this badass custom sim racing switch panel designed by Jordan.With awesome materials like carbon fiber, 6061 T6 aluminum, and 304 stainless steel, we can help you realize your most “out there” laser cut .

Roll-out metal sheet racks make sheet metal much easier to handle with cranes, hoists and forklifts and can handle very heavy loads in a tight space. Standard capacities of 5,000 pounds per shelf can be expanded to 10,000 pounds in certain sizes and configurations.

For Sheet Metal users, the new features in SOLIDWORKS 2025 are sure to excite. In addition to never-before-seen bend notches, the list of enhancements to existing features is long, so let's dive in. Sheet Metal and Weldment Bodies. This part contains a mixture of .Ideas Inc has 40 years of experience in the field of precision sheet metal fabrication. Our 20,000 square foot facility is located in Lowell, Massachusetts. Our capabilities range from small lot quick turn prototypes to mass production. We manufacture anything from the simplest brackets to complex assemblies.

NORCK provides on-demand CNC machining, plastic and metal 3D printing, rapid prototyping, & sheet metal fabrication services. Precision parts, fast turnaround. Get a quote! . Injection Molding: Norck's Expertise in Transforming Ideas into Precision Plastic Parts Injection molding is a cornerstone of modern manufacturing, enabling the mass .

sheet metal project ideas

U-Bracket. Unlike your L-bracket, this bracket is curved along two axes, giving a U-shaped contour. You can use the U-brackets to hold an item between flanges or install horizontal plane parallel items above each other. Z-Bracket. A metal bracket with .

sheet metal parts ideas|metalwork projects for students