catia sheet metal drawings for practice In this tutorial you will learn CATIA sheet metal basics. CATIA sheet metal tools shown in this tutorial are: Sheet Metal Parameters, Wall, Wall on Edge and CATIA wall on edge.

In this article, we’ll give you the lowdown on sheet metal forming, including the various processes, suitable materials, and its pros and cons. What is Sheet Metal Forming? Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components.

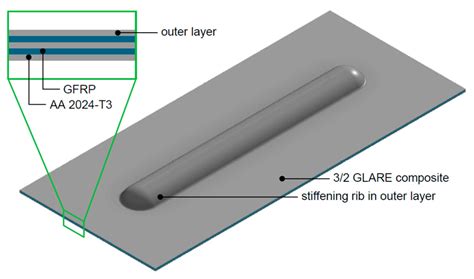

0 · sheet metal stiffening rib design

1 · sheet metal design practice pdf

2 · sheet metal design for practice

3 · sheet metal design book pdf

4 · CATIA sheet metal tutorial

5 · CATIA sheet metal exercises pdf

6 · CATIA sheet metal design pdf

7 · CATIA bend from flat

A deep drawing is a manufacturing technique that transforms a metal sheet into a three-dimensional form through mechanical action. Usually executed using a punch, die, and other tools, this method is perfect for hollow, axisymmetrical parts.

user interface. It provides an associative feature-based modeling, making it possible to design sheet metal parts in concurrent engineering between the unfolded or folded part . In this tutorial we will create some of the CATIA sheet metal practice drawings and solve CATIA sheet metal de.

Follow My site Link For Technical Drawings Sheetmetal Practice Design Drawing Sheet: 👇👇👇👇👇 http://caddesigns.in/sheetmetal-catia.Learn how to create details like cutouts, corner relief, and stamps in the sheet metal part. Learn the methods to reuse or duplicate existing parts or features using patterns, powercopy, user-defined stamps, and more. Learn how to . Creating sheet metal parts from flat patterns; Adding bends and other sheet metal features; Creating flanges, hems, and other details; Using unfolded and folded views; Working . In this tutorial you will learn CATIA sheet metal basics. CATIA sheet metal tools shown in this tutorial are: Sheet Metal Parameters, Wall, Wall on Edge and CATIA wall on edge.

Overview: Through this course, the user will be able to learn CATIA V5 Sheet Metal Design. On completion of this course, user will be able to: Understand the Sheet Metal parameter settings; Create Wall, Cut Out, Hole, Hem, Tear, Drop .

This training course enables you to create features that are specific to the sheet metal modeling process. You are provided with a process-based approach to creating sheet metal models. . We can now define a stamp based on profile containing a punch and die sketch, a 3D curve sketch or a sketch with several inner contours. We can now create a pattern from a flange on rectangular, circular or user-defined .

Dedicated drawing capability including unfolded view and specific settings. All sheet metal specifications can be re-used by the Knowledge Advisor workbench to capture corporate knowledge and increase the quality of designs. Natively integrated, SheetMetal Design offers the same ease of use and user interface consistency as all V5 applications.

user interface. It provides an associative feature-based modeling, making it possible to design sheet metal parts in concurrent engineering between the unfolded or folded part representation. Generative Sheetmetal Design offers the following main functions: Associative and dedicated sheet metal feature-based modeling

In this tutorial we will create some of the CATIA sheet metal practice drawings and solve CATIA sheet metal de.Follow My site Link For Technical Drawings Sheetmetal Practice Design Drawing Sheet: 👇👇👇👇👇 http://caddesigns.in/sheetmetal-catia.

Learn how to create details like cutouts, corner relief, and stamps in the sheet metal part. Learn the methods to reuse or duplicate existing parts or features using patterns, powercopy, user-defined stamps, and more. Learn how to generate sheet metal part drawings and sheet metal order process. This website stores cookies on your computer. Creating sheet metal parts from flat patterns; Adding bends and other sheet metal features; Creating flanges, hems, and other details; Using unfolded and folded views; Working with sheet metal parameters; Troubleshooting sheet metal design problems; Define Louvre and Bead stampings

In this tutorial you will learn CATIA sheet metal basics. CATIA sheet metal tools shown in this tutorial are: Sheet Metal Parameters, Wall, Wall on Edge and CATIA wall on edge.Overview: Through this course, the user will be able to learn CATIA V5 Sheet Metal Design. On completion of this course, user will be able to: Understand the Sheet Metal parameter settings; Create Wall, Cut Out, Hole, Hem, Tear, Drop and Hopper; Understand types of Flanges and Stamping; Create Punch and Die; Understand the use of Unfolded and .

This training course enables you to create features that are specific to the sheet metal modeling process. You are provided with a process-based approach to creating sheet metal models. Each step in the process is discussed in depth using lectures and several hands-on practices. We can now define a stamp based on profile containing a punch and die sketch, a 3D curve sketch or a sketch with several inner contours. We can now create a pattern from a flange on rectangular, circular or user-defined patterns. Selecting a ruled surface is now possible when creating a hopper.Dedicated drawing capability including unfolded view and specific settings. All sheet metal specifications can be re-used by the Knowledge Advisor workbench to capture corporate knowledge and increase the quality of designs. Natively integrated, SheetMetal Design offers the same ease of use and user interface consistency as all V5 applications.

user interface. It provides an associative feature-based modeling, making it possible to design sheet metal parts in concurrent engineering between the unfolded or folded part representation. Generative Sheetmetal Design offers the following main functions: Associative and dedicated sheet metal feature-based modeling

In this tutorial we will create some of the CATIA sheet metal practice drawings and solve CATIA sheet metal de.Follow My site Link For Technical Drawings Sheetmetal Practice Design Drawing Sheet: 👇👇👇👇👇 http://caddesigns.in/sheetmetal-catia.

Learn how to create details like cutouts, corner relief, and stamps in the sheet metal part. Learn the methods to reuse or duplicate existing parts or features using patterns, powercopy, user-defined stamps, and more. Learn how to generate sheet metal part drawings and sheet metal order process. This website stores cookies on your computer. Creating sheet metal parts from flat patterns; Adding bends and other sheet metal features; Creating flanges, hems, and other details; Using unfolded and folded views; Working with sheet metal parameters; Troubleshooting sheet metal design problems; Define Louvre and Bead stampings

In this tutorial you will learn CATIA sheet metal basics. CATIA sheet metal tools shown in this tutorial are: Sheet Metal Parameters, Wall, Wall on Edge and CATIA wall on edge.Overview: Through this course, the user will be able to learn CATIA V5 Sheet Metal Design. On completion of this course, user will be able to: Understand the Sheet Metal parameter settings; Create Wall, Cut Out, Hole, Hem, Tear, Drop and Hopper; Understand types of Flanges and Stamping; Create Punch and Die; Understand the use of Unfolded and .This training course enables you to create features that are specific to the sheet metal modeling process. You are provided with a process-based approach to creating sheet metal models. Each step in the process is discussed in depth using lectures and several hands-on practices.

sheet metal stiffening rib design

sheet metal design practice pdf

A K-Factor will typically range between 0 and .5 for standard materials and thicknesses though smaller and larger K-Factors are possible. To help you begin I’ve included a K-Factor Chart below which contains common K-Factor starting points, good for general . See more

catia sheet metal drawings for practice|CATIA bend from flat