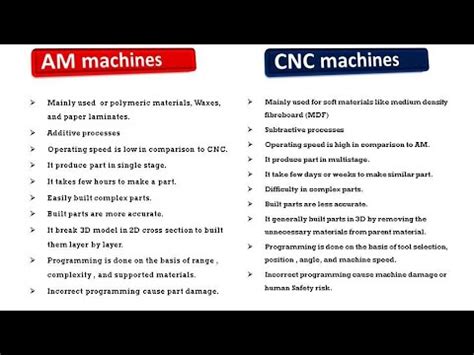

cnc additive manufacturing Additive Manufacturing (AM) and CNC (Computer Numerical Control) manufacturing are two dominant prototyping methods. Understanding the differences between these methods is .

Original equipment replacement downtube Di2 junction box for Trek Madone 9 Series frames

0 · cnc machining vs am

1 · cnc machining additive powder

2 · additive manufacturing vs subtraction manufacturing

3 · additive manufacturing vs cnc

4 · additive manufacturing subtractive

5 · additive manufacturing services

6 · 3d printing vs additive manufacturing

7 · 3d printing additive powder

We have over 30,000 square feet devoted to MIG, TIG, spot, stud, and robot welding. Our welding department can produce parts in nearly every material, including mild steel, stainless and aluminum. If you require thin or heavy gauge materials, we have qualified personnel to ensure quality workmanship.

cnc machining vs am

For Keselowski Advanced Manufacturing (KAM), success with additive manufacturing happens on the so-called “subtractive” machines. The Statesville, North Carolina, company produces highly engineered metal .Additive manufacturing, commonly known as 3D printing, is a process where objects are built layer by layer from digital models. Unlike subtractive manufacturing, which removes material, additive manufacturing adds material .

best cnc mini lathe machine

By understanding the intricacies of Additive Manufacturing and CNC Machining, we can discern the substantial impact these technologies have on various industries. This comprehension also assists us in forecasting future trends . The difference between additive manufacturing and CNC machining comes down to their core approaches: additive manufacturing builds parts layer by layer, offering design freedom and efficient prototyping, while .In the realm of modern manufacturing, CNC Subtractive Manufacturing (CSM) stands as the bedrock of precision, versatility, and top-notch surface quality. Conversely, Additive Manufacturing (AM) represents an exciting frontier for .

Additive Manufacturing (AM) and CNC (Computer Numerical Control) manufacturing are two dominant prototyping methods. Understanding the differences between these methods is . Here is a look at just some of the ways additive and machining interrelate right now. A donut-shaped machine tool component called the AKZ FDS adapter illustrates the increasingly intricate links between additive .

Two of the most dominant manufacturing technologies in the industry today are Additive Manufacturing (AM) and CNC (Computer Numerical Control) Machining. While both have their . CNC machining and additive manufacturing both have their advantages. Learn where AM is more beneficial, specifically for producing metal-forming dies.Motivation and requirements for CNC machining to deal with additive manufacturing and its integration in machine tools

For Keselowski Advanced Manufacturing (KAM), success with additive manufacturing happens on the so-called “subtractive” machines. The Statesville, North Carolina, company produces highly engineered metal components for industries including aerospace and defense through laser powder bed fusion (LPBF) on 20 metal additive machines.Additive manufacturing, commonly known as 3D printing, is a process where objects are built layer by layer from digital models. Unlike subtractive manufacturing, which removes material, additive manufacturing adds material to create the final part.By understanding the intricacies of Additive Manufacturing and CNC Machining, we can discern the substantial impact these technologies have on various industries. This comprehension also assists us in forecasting future trends towards more . The difference between additive manufacturing and CNC machining comes down to their core approaches: additive manufacturing builds parts layer by layer, offering design freedom and efficient prototyping, while CNC machining subtracts material to achieve high precision, repeatability, and smooth finishes in production.

In the realm of modern manufacturing, CNC Subtractive Manufacturing (CSM) stands as the bedrock of precision, versatility, and top-notch surface quality. Conversely, Additive Manufacturing (AM) represents an exciting frontier for intricate designs, yet it faces limitations in industries that demand speed of manufacture, precision, material .Additive Manufacturing (AM) and CNC (Computer Numerical Control) manufacturing are two dominant prototyping methods. Understanding the differences between these methods is crucial for businesses and designers looking to improve their new product development processes. Here is a look at just some of the ways additive and machining interrelate right now. A donut-shaped machine tool component called the AKZ FDS adapter illustrates the increasingly intricate links between additive manufacturing (AM) and CNC machining. A version of this article was our cover story in the December 2022 issue of Modern Machine Shop.Two of the most dominant manufacturing technologies in the industry today are Additive Manufacturing (AM) and CNC (Computer Numerical Control) Machining. While both have their unique advantages, they serve diverse purposes and function with distinct mechanisms.

CNC machining and additive manufacturing both have their advantages. Learn where AM is more beneficial, specifically for producing metal-forming dies.Motivation and requirements for CNC machining to deal with additive manufacturing and its integration in machine tools For Keselowski Advanced Manufacturing (KAM), success with additive manufacturing happens on the so-called “subtractive” machines. The Statesville, North Carolina, company produces highly engineered metal components for industries including aerospace and defense through laser powder bed fusion (LPBF) on 20 metal additive machines.

Additive manufacturing, commonly known as 3D printing, is a process where objects are built layer by layer from digital models. Unlike subtractive manufacturing, which removes material, additive manufacturing adds material to create the final part.By understanding the intricacies of Additive Manufacturing and CNC Machining, we can discern the substantial impact these technologies have on various industries. This comprehension also assists us in forecasting future trends towards more . The difference between additive manufacturing and CNC machining comes down to their core approaches: additive manufacturing builds parts layer by layer, offering design freedom and efficient prototyping, while CNC machining subtracts material to achieve high precision, repeatability, and smooth finishes in production.In the realm of modern manufacturing, CNC Subtractive Manufacturing (CSM) stands as the bedrock of precision, versatility, and top-notch surface quality. Conversely, Additive Manufacturing (AM) represents an exciting frontier for intricate designs, yet it faces limitations in industries that demand speed of manufacture, precision, material .

Additive Manufacturing (AM) and CNC (Computer Numerical Control) manufacturing are two dominant prototyping methods. Understanding the differences between these methods is crucial for businesses and designers looking to improve their new product development processes. Here is a look at just some of the ways additive and machining interrelate right now. A donut-shaped machine tool component called the AKZ FDS adapter illustrates the increasingly intricate links between additive manufacturing (AM) and CNC machining. A version of this article was our cover story in the December 2022 issue of Modern Machine Shop.Two of the most dominant manufacturing technologies in the industry today are Additive Manufacturing (AM) and CNC (Computer Numerical Control) Machining. While both have their unique advantages, they serve diverse purposes and function with distinct mechanisms. CNC machining and additive manufacturing both have their advantages. Learn where AM is more beneficial, specifically for producing metal-forming dies.

cnc machining additive powder

additive manufacturing vs subtraction manufacturing

best cnc machines for education

additive manufacturing vs cnc

Tri-Metal Fabricators in Surrey is known for producing quality steel and sheet metal products for a variety of industrial sectors, and it does so in a 36,000 square foot plant equipped with laser and plasma cutters, massive rollers and specialized equipment.

cnc additive manufacturing|cnc machining additive powder