cnc aerospace wings part quotes What is Aerospace CNC Machining? This CNC machining process involves creating CNC machining aerospace parts to assemble and maintain aircraft and space shuttles. Aerospace CNC machining companies use kits, . After one to three coats, remove any imperfections with 1,000-grit sandpaper, then add a couple coats of hammer-finish spray paint on the .

0 · The Ultimate Guide to CNC Machining Aerospace Parts

1 · Precision CNC Machining for Aerospace Parts

2 · CNC Milling for Aerospace: Precision and Perfection

3 · CNC Machining for Aerospace: Everything You Need to Know

4 · CNC Machining For Aerospace Industry: Benefits, Applications,

5 · CNC Machining Aerospace Parts: The Ultimate Guide

6 · Aerospace CNC Machining: A Complete Guide to Precision

7 · Aerospace CNC Machining: A Complete Guide to

The standard size of a roofing sheet is typically around 10 to 12 feet in length, with a width of 20 to 24 inches. The size of the sheet can vary depending on the make and model, as well as local conditions and building codes. Certain areas may require larger sheets, or be limited to smaller sheets for environmental or other reasons.

The Ultimate Guide to CNC Machining Aerospace Parts

For specific aerospace parts, precise design and engineering planning are crucial. We utilize advanced CAD software for part design and ensure every detail aligns with the stringent standards of the aerospace industry through precise engineering analysis. AN-Prototype’s CNC machine shop can provide aerospace prototypes and precision machined components to the aerospace industry using advanced CNC machining equipment. Efficient CNC machining helps achieve .

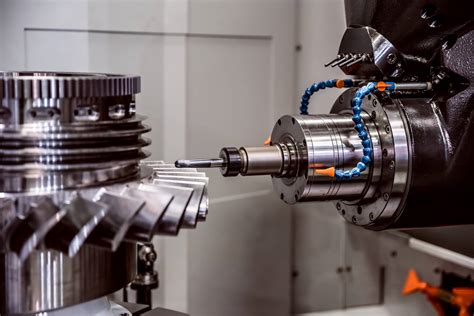

Learn about the benefits of multi-axis CNC machining in producing complex geometries required for aerospace components with unparalleled precision. As you can see, CNC machining plays .

electric break gear box

What is Aerospace CNC Machining? This CNC machining process involves creating CNC machining aerospace parts to assemble and maintain aircraft and space shuttles. Aerospace CNC machining companies use kits, . Aerospace CNC machining is a process that uses computer-guided tools to produce precision parts for the aerospace sector. Why is CNC .Choose Fictiv for CNC Aerospace Machining. Fictiv provides aerospace CNC machining services for aerospace companies and others and works with a carefully vetted network of AS9100 .CNC machining has significantly improved the manufacturing process and enhanced the performance .

For specific aerospace parts, precise design and engineering planning are crucial. We utilize advanced CAD software for part design and ensure every detail aligns with the stringent standards of the aerospace industry through precise engineering analysis. AN-Prototype’s CNC machine shop can provide aerospace prototypes and precision machined components to the aerospace industry using advanced CNC machining equipment. Efficient CNC machining helps achieve tolerance levels as high as 0.002 mm, creating aerospace-grade plastics and metals.

Learn about the benefits of multi-axis CNC machining in producing complex geometries required for aerospace components with unparalleled precision. As you can see, CNC machining plays a vital role in the aerospace industry, enabling the production of high-quality parts that meet the industry's rigorous standards. What is Aerospace CNC Machining? This CNC machining process involves creating CNC machining aerospace parts to assemble and maintain aircraft and space shuttles. Aerospace CNC machining companies use kits, components, and assemblies which are essential for crafts used in the aerospace industry.

Aerospace CNC machining is a process that uses computer-guided tools to produce precision parts for the aerospace sector. Why is CNC milling preferred in aerospace? Due to its precision, consistency, and ability to handle complex geometries, CNC milling is the go-to choice for aerospace components.Choose Fictiv for CNC Aerospace Machining. Fictiv provides aerospace CNC machining services for aerospace companies and others and works with a carefully vetted network of AS9100 certified manufacturers. Importantly, we also provide complex parts at ridiculous speeds. CNC machining has significantly improved the manufacturing process and enhanced the performance of aerospace parts. This section explores the many benefits of CNC machining, with a particular focus on its contribution to the manufacture of lightweight, error-free, and highly consistent components. When manufacturing aerospace components using CNC machining, several key steps are involved to ensure precision, quality, and adherence to industry standards. CNC Aerospace Manufacturing. Here’s an overview of the process: 1. Design and Programming.

CNC machining helps companies like SpaceX, NASA and Blue Origin to design, process and manufacture aerospace components from start to finish. Whether it’s manufacturing the outer shell of a rocket or the smallest component of a jet engine, CNC machining delivers the high level of precision needed. Aerospace parts come in a wide variety of shapes, sizes, and materials, and CNC machines can handle them all. Whether it’s aluminum, titanium, stainless steel, or even exotic materials like Inconel, CNC machines can cut, shape, and drill with precision and ease.

For specific aerospace parts, precise design and engineering planning are crucial. We utilize advanced CAD software for part design and ensure every detail aligns with the stringent standards of the aerospace industry through precise engineering analysis.

AN-Prototype’s CNC machine shop can provide aerospace prototypes and precision machined components to the aerospace industry using advanced CNC machining equipment. Efficient CNC machining helps achieve tolerance levels as high as 0.002 mm, creating aerospace-grade plastics and metals.

Learn about the benefits of multi-axis CNC machining in producing complex geometries required for aerospace components with unparalleled precision. As you can see, CNC machining plays a vital role in the aerospace industry, enabling the production of high-quality parts that meet the industry's rigorous standards. What is Aerospace CNC Machining? This CNC machining process involves creating CNC machining aerospace parts to assemble and maintain aircraft and space shuttles. Aerospace CNC machining companies use kits, components, and assemblies which are essential for crafts used in the aerospace industry. Aerospace CNC machining is a process that uses computer-guided tools to produce precision parts for the aerospace sector. Why is CNC milling preferred in aerospace? Due to its precision, consistency, and ability to handle complex geometries, CNC milling is the go-to choice for aerospace components.Choose Fictiv for CNC Aerospace Machining. Fictiv provides aerospace CNC machining services for aerospace companies and others and works with a carefully vetted network of AS9100 certified manufacturers. Importantly, we also provide complex parts at ridiculous speeds.

CNC machining has significantly improved the manufacturing process and enhanced the performance of aerospace parts. This section explores the many benefits of CNC machining, with a particular focus on its contribution to the manufacture of lightweight, error-free, and highly consistent components. When manufacturing aerospace components using CNC machining, several key steps are involved to ensure precision, quality, and adherence to industry standards. CNC Aerospace Manufacturing. Here’s an overview of the process: 1. Design and Programming.CNC machining helps companies like SpaceX, NASA and Blue Origin to design, process and manufacture aerospace components from start to finish. Whether it’s manufacturing the outer shell of a rocket or the smallest component of a jet engine, CNC machining delivers the high level of precision needed.

electric cable box

To properly lubricate bronze bushings, the interior of the bushing needs to be accessed, requiring removal of any shafts or accessories the bushing is designed to hold. If .

cnc aerospace wings part quotes|The Ultimate Guide to CNC Machining Aerospace Parts