sheet metal hemming process Sheet metal hemming is a manufacturing process that folds metal edges to reinforce strength and safety. It reduces sharpness and enhances aesthetics, often used in . Windsor (/ ˈwɪndzər / WIND-zer) is a city in southwestern Ontario, Canada, on the south bank of the Detroit River directly across from Detroit, Michigan, United States.

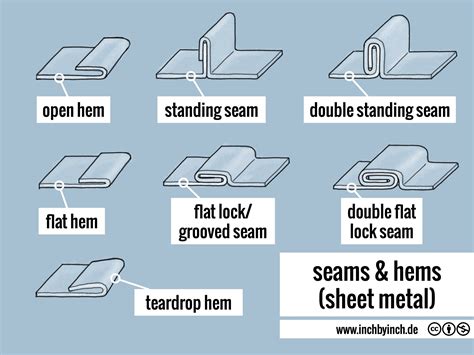

0 · types of sheet metal seams

1 · sheet metal hem design guide

2 · sheet metal hand hemming tool

3 · seaming process in sheet metal

4 · seam joint in sheet metal

5 · open hem sheet metal

6 · hemmed edge sheet metal

7 · hem300 vs hem305

Wingfield Structural is based in Edinburgh, South Australia and offer specialized services in commercial & domestic steel manufacturing, fabrication & erection.

Hemming in sheet metal operations refers to the bending of a sheet metaledge onto itself. It is very similar to edge stitching in clothes. Similar to how an edge stitch strengthens the edge and makes it more durable, a hem imparts strength to the metal edge and improves its appearance. The edge of one part may . See moreThe hemming process can be carried out in one of the following two ways: 1. Die hemming process 2. Roller hemming process See more

A seam is used to connect two metal parts by interlocking the edges of the folded sheet metal parts. The resulting shape may even form a . See more Sheet metal hemming is a manufacturing process that folds metal edges to reinforce strength and safety. It reduces sharpness and enhances aesthetics, often used in . Explore how the sheet metal hemming process improves the structural integrity of sheet metal parts. Learn about hem types and their applications. In sheet metal fabrication, the hemming process involves bending the same part’s sharp edges to form a reinforcement channel. This process is widely used across the automotive and electronics industries. It cuts thin sheet .

Hemming Procedure. The hemming tool or press brake bends the metal sheet’s edge at a 90º angle and folds the initially bent edge back onto the metal sheet to form a hem. After, clutch the hem to ensure a secure and firm .

Sheet metal hem is a fabrication process where the edge of sheet metal is folded over onto itself, creating a smooth, rounded finish that enhances the final product’s safety and aesthetic appeal. This post will take you through the .

Sheet Metal Hemming Vs. Sheet Metal Seaming. The rolling over of a sheet metal edge onto itself is known as hemming in the metalworking industry. Hemming includes rolling the edge flush against itself instead of sewing, which joins the .As we mentioned above, sheet metal hemming is a process of folding the edge of a single metal sheet back onto itself to create a clean, finished edge. This is typically done by bending the .Hemming and seaming are two similar metalworking processes in which a sheet metal edge is rolled over onto itself. Hemming is the process in which the edge is rolled flush to itself, while a .

August 31, 2024. Contents. Struggling with sheet metal edges issues? Hemming is the solution. Rough edges not only look unprofessional but can also be harmful. This important technique makes safe, smooth and durable edges for different . Hemming suits only high-gauge sheet metal (thinner sheets <=0.125”). Low-gauge sheets (thicker sheets) are prone to fracturing on bending. How Sheet Metal Hemming Works. Sheet metal hemming is a multi-step .

In hemming, the sheet-metal parts are bent in a forming process and then positively joined by welding or brazing. Firstly, the edge of the sheet metal is bent over. The component is stiffened and can subsequently be joined. Hemming is also capable of joining different components.

hemming process A closed hem A seam. Hemming and seaming are two similar metalworking processes in which a sheet metal edge is rolled over onto itself. Hemming is the process in which the edge is rolled flush to itself, while a seam joins the edges of two materials. [1]Hems are commonly used to reinforce an edge, hide burrs and rough edges, and improve appearance. When to apply the 4 Common Types of Sheet Metal Hems to your Design 1. Closed hem. Also known as a crushed hem, a closed hem is completely flush (as opposed to an open hem, which allows for a bit of space in the bend).. Closed hems are the most popular type of hem because they’re so easy to make: the sheet metal is simply flattened onto itself.

In sheet metal hemming means to fold the metal back on itself. When working with a Brake Press hems are always created in a two step process: Create a bend with Acute Angle Tooling in the metal, 30° is preferable but 45° will work for some circumstances. Hemming is a sheet metal forming process in which sheets are joined by bending it usually to 180°. Automotive body panels and automotive parts such as deck-lids, trunk-lids, doors, hoods and tailgates are formed by hemming process. This paper present a systematic review of sheet metal hemming process based on materials used in hemming process .

The Sheet Metal Hem Process: A Step-by-Step Guide. After the preparation is complete, the heart of the procedure is the sheet metal hemming. To ensure quality and consistency, our team follows a step-by-step process. Bending and folding Techniques.Hemming (or flattening) is a great way to finish sharp edges and to strengthen parts after bending sheet metal. 443-459-5496 Find your local dealer

types of sheet metal seams

In the manufacturing industry, the sheet metal process is common, and sheet metal parts are used in many different industries, including consumer products, appliances, aircraft, and the automotive and aerospace sectors. Sheet Metal Operations. Following are the 9 different types of sheet metal operations: Shearing Operations; Blanking Operations Sheet metal hemming is a multi-step process that makes strong, smooth edges. First, the metal sheet is cut to size and the edge is bent at a 90-degree angle. Next, the bent edge is folded back onto itself at a 180-degree angle. It makes a double layer of metal along the edge. The folded edge is then flattened by using particular tools or machines. Introduction Hemming is a forming process that is applied by folding the edge regions of the sheet metal on itself. The hemming process is a bending process that is applied intensively for purposes such as joining more than one piece as Hamedon et al. (2014) investigated in their work, obtaining a more durable structure in the edge areas, and . Welcome to Kreatorzone! On this sheet metal design series you will find the recommended Common sheet metal design guidelines in Hem Feature Guidelines or Hem.

As we mentioned above, sheet metal hemming is a process of folding the edge of a single metal sheet back onto itself to create a clean, finished edge. This is typically done by bending the metal over a die or roller, resulting in a 180-degree fold or a tighter, more acute angle. Hemming provides a smooth, rounded edge that is less prone to .Here are the benefits of this process: Sheet Metal Hemming – Aesthetic improvements. Applying a hemming procedure on your sheet metal materials can help improve the aesthetics of the final product. Hemming edges are even more tidy compared to the un-hemmed edges. Better-looking edges will increase the overall value of your sheet metal products. Metal hemming is a vital process in the field of sheet metal fabrication and manufacturing. It involves bending, folding, or curling the edge of a metal sheet to create a secure, finished, and aesthetically pleasing joint. Abstract. Hemming is a material processing technology widely used in major sectors such as automotive and aerospace industries. As a mechanical joining process, hemming is applied to sheet metal components to .

To guarantee a good sheet hemming operation, make sure the metal sheet is horizontal and devoid of contaminants that might impede the process. Then, position the hemming tool to get the desired hem width and . The conditions and rules for press brake forming hems on sheet metal. Learn more at https://www.allmetalsfab.comHemming is a common sheet metal technique use.Influence of different pre-hem paths on the flange geometry was studied first. Among these paths could be vertical, oblique, horizontal. The result of the simulation shows that the vertical pre-hem path leads to less creep. To avoid the hemming quality defects around the corner of the outer-sheet, influence of the structure of the pre-processing steel on the hemming force was studied.

high precision cnc medical spare parts

Hemming is a sheet metal forming process in which sheets are joined by bending it usually to 180 . Automotive body panels and automotive parts such as deck-lids, trunk-lids, doors, hoods and .A vision-based automatic compensation path to achieve a dies-free roller hemming process is proposed and investigated and validated with experimental measurements for the sheet offset and the compensation of the arm hemming position.Hemming. Hemming is a forming and joining technique used in sheet-metal working. This technology can be used to join components of the same material or different materials – one reason why the process is frequently used in the automotive industry.

As we mentioned above, sheet metal hemming is a process of folding the edge of a single metal sheet back onto itself to create a clean, finished edge. This is typically done by bending the metal over a die or roller, resulting in a 180-degree fold or a tighter, more acute angle. Hemming provides a smooth, rounded edge that is less prone to .As we mentioned above, sheet metal hemming is a process of folding the edge of a single metal sheet back onto itself to create a clean, finished edge. This is typically done by bending the metal over a die or roller, resulting in a 180-degree fold or a tighter, more acute angle. Hemming provides a smooth, rounded edge that is less prone to .Sheet Metal Forming 2.810 D. Cooper !“Sheet Metal Forming” Ch. 16 Kalpakjian !“Design for Sheetmetal Working”, Ch. 9 Boothroyd, Dewhurst and Knight Sheet metal is widely used in the automotive and electronics industries. However, its sharp edges can warp over time and pose a safety risk. To address this, the edges are often folded in a process known as sheet metal hemming. This article explains what is .

The process, called hole hemming, involves deforming the metal sheet to establish a mechanical interlock with the polymer sheet, requiring neither heating nor auxiliary elements. The applicability of this process is tested for joining aluminum and polycarbonate (PC) sheets.

hickory harbor stainless steel hardware for kitchen cabinets

In this blog post, we will explore the key factors that affect MIG welding sheet metal, including wire size, gas selection, amperage, and voltage. We will also provide tips and best practices to help you achieve optimal .

sheet metal hemming process|seaming process in sheet metal