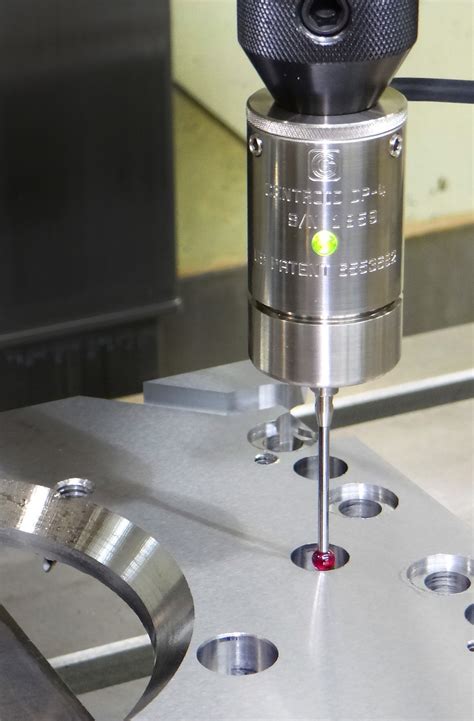

cnc machine probe What is a Probe in CNC Machining? A probe is an extremely sensitive switching device designed to originate and send signals, providing accurate, repeatable geometric data. Probes are used to inspect and measure .

The ZN151 - Abrites Distribution Box Set is a proprietary set of a Distribution box device with accompanying cables and pins, allowing the AVDI to connect to different vehicles and modules, with CAN and K-Line protocols. It provides in-vehicle connection options, as .

0 · touch probes for cnc machines

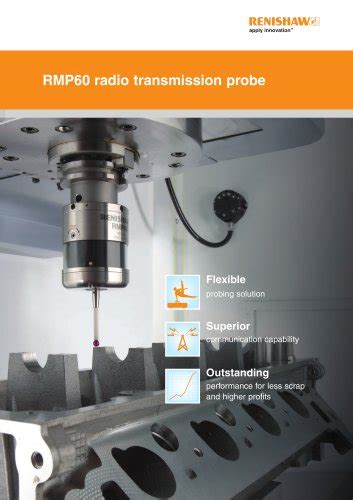

1 · renishaw probes catalog

2 · renishaw probe tip catalog

3 · renishaw probe price list

4 · renishaw probe price

5 · renishaw probe for sale

6 · probe tool for cnc

7 · cnc tool setter probe

In most cases, roofing experts will recommend capable ventilation when installing your metal roof. Ventilation contributes to your other air flow and filtering preparations that help you enjoy a liveable and breathable space even in humid climates. This is especially important for infants and the elderly.

touch probes for cnc machines

Precise workpiece and tool measurement on a CNC machine helps to achieve accurate and consistent machining results, enhancing productivity, and minimising the risk of costly errors. .Hard-wired probe systems connect directly to the machine tool controller via a .

renishaw probes catalog

Achieve precise and efficient CNC machining with our automated on .

Enhance the efficiency of your CNC machining centres and lathes with our innovative range of automated machine tool probes for workpiece setting and inspection. Streamline your operations and maximise your productivity with .

Achieve precise and efficient CNC machining with our automated on-machine tool setters and broken tool detectors. Explore our range of contact and non-contact solutions for CNC machines. Broken tool detectors identify whether tools .

What is a Probe in CNC Machining? A probe is an extremely sensitive switching device designed to originate and send signals, providing accurate, repeatable geometric data. Probes are used to inspect and measure .

Touch probes help reduce setup times, increase machine usage time, and improve the dimensional accuracy of the finished workpieces. Setup, measuring, and monitoring functions .Precise workpiece and tool measurement on a CNC machine helps to achieve accurate and consistent machining results, enhancing productivity, and minimising the risk of costly errors. Machine tool probes for workpiece setting and inspection gather data on the shape, size, and position of a workpiece.

Enhance the efficiency of your CNC machining centres and lathes with our innovative range of automated machine tool probes for workpiece setting and inspection. Streamline your operations and maximise your productivity with machine tool probing.

renishaw probe tip catalog

Achieve precise and efficient CNC machining with our automated on-machine tool setters and broken tool detectors. Explore our range of contact and non-contact solutions for CNC machines. Broken tool detectors identify whether tools inside a machine tool are broken or intact. What is a Probe in CNC Machining? A probe is an extremely sensitive switching device designed to originate and send signals, providing accurate, repeatable geometric data. Probes are used to inspect and measure geometric characteristics of machined features or machining tools.Touch probes help reduce setup times, increase machine usage time, and improve the dimensional accuracy of the finished workpieces. Setup, measuring, and monitoring functions can be performed manually or—in conjunction with most CNC controls—can be controlled by .3D Touch probes for fast workpiece measurement and workpiece referencing in CNC machines: faster, more precise, more robust.

What is Machine Tool Probing System? The probing system is a measuring tool configured on CNC machines to measure the features of CNC machined parts, correct the coordinate system, recognize error, etc., after partial or final machining operation, which can improve the machining quality of the manufacturing equipment, reduce cost and save time.Harbin Pioneer offers precise touch probe System & software for CNC machines. It can measure and find the base position of the workpiece quickly and accurately, set or modify the workpiece coordinate automatically. How to select the best touch probe for workpiece and tool measurement. Touch probes are available in various types to meet measurement needs for machining centers, milling, drilling, and boring machines, as well as on CNC lathes. Here are some things to consider when assessing touch probes for workpiece and tool measurement: Connectivity

The CENTROID KP-3 CNC Touch probe is designed for Probing (part setup, zero location setup, and CMM type location and measurement of part geometry), component/fixture/work piece setup, inspection and 3D or 2D digitizing/surfacing.

Precise workpiece and tool measurement on a CNC machine helps to achieve accurate and consistent machining results, enhancing productivity, and minimising the risk of costly errors. Machine tool probes for workpiece setting and inspection gather data on the shape, size, and position of a workpiece.

Enhance the efficiency of your CNC machining centres and lathes with our innovative range of automated machine tool probes for workpiece setting and inspection. Streamline your operations and maximise your productivity with machine tool probing.Achieve precise and efficient CNC machining with our automated on-machine tool setters and broken tool detectors. Explore our range of contact and non-contact solutions for CNC machines. Broken tool detectors identify whether tools inside a machine tool are broken or intact. What is a Probe in CNC Machining? A probe is an extremely sensitive switching device designed to originate and send signals, providing accurate, repeatable geometric data. Probes are used to inspect and measure geometric characteristics of machined features or machining tools.Touch probes help reduce setup times, increase machine usage time, and improve the dimensional accuracy of the finished workpieces. Setup, measuring, and monitoring functions can be performed manually or—in conjunction with most CNC controls—can be controlled by .

3D Touch probes for fast workpiece measurement and workpiece referencing in CNC machines: faster, more precise, more robust. What is Machine Tool Probing System? The probing system is a measuring tool configured on CNC machines to measure the features of CNC machined parts, correct the coordinate system, recognize error, etc., after partial or final machining operation, which can improve the machining quality of the manufacturing equipment, reduce cost and save time.

Harbin Pioneer offers precise touch probe System & software for CNC machines. It can measure and find the base position of the workpiece quickly and accurately, set or modify the workpiece coordinate automatically. How to select the best touch probe for workpiece and tool measurement. Touch probes are available in various types to meet measurement needs for machining centers, milling, drilling, and boring machines, as well as on CNC lathes. Here are some things to consider when assessing touch probes for workpiece and tool measurement: Connectivity

3 leg metal bracket

renishaw probe price list

renishaw probe price

renishaw probe for sale

Crafted from a thick gauge, fully seam welded galvanized steel base, all Metallic Series planters are proven to resist weather-related issues such Multiple Sizes; Available in Black, Gray & White Low and Long.

cnc machine probe|renishaw probe price list