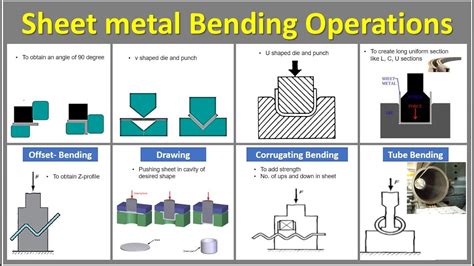

breaking sheet metal Bending is one of the most common sheet metal fabrication operations. Also known as press braking , flanging, die bending, folding and edging , this method is used to deform a material to an angular shape. $8.99

0 · types of bending sheet metal

1 · step bending sheet metal

2 · sheet metal cutting and bending

3 · sheet metal brake bending angle

4 · sheet metal bending strength

5 · sheet metal bending diagram

6 · bending tool for sheet metal

7 · bending sheet metal 90 degrees

Stainless Steel Litter Box with Metal Lid and Scoop - Enclosed Metal Litter Box for Large Cats, Rust-Resistant, Odor-Control, Easy to Clean, Durable & Long-Lasting with Round Edge (L)

durable metal lunch box

Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet . Bending is one of the most common sheet metal fabrication operations. Also known as press braking , flanging, die bending, folding and edging , this method is used to deform a material to an angular shape.

Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake.The process of stiffening sheet metal--known as cross braking--places a small bend across flat sections of metal. Each bend reduces the flat area of each side, increasing its overall strength. Increase the gap between the top and bottom dies of sheet metal brake by either pushing the clamping leaf handle away from the front of the brake or .A Cross Break in sheet metal is when multiple obtuse Bend Angles of approximately 170° are made across a flat section thin metal. Cross breaks are most commonly in an X shape, forming a slight pyramid shape in the metal without overly distorting it.#artfullyrogue #makingalivingasamaker #metalartistIf you do metal work, at some point you will need to bend sheet metal. And if you're not ready to invest in.

dutch lap electrical box

When stiffening ductwork or other sheet metal products, there are two primary techniques fabricators can employ, cross-braking or beading. Before we get into the specifics of how and when to perform each technique, let’s take a step back and ask the question, “Why should I stiffen my sheet, anyway?”This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending and material selection information. Don't let sheet metal bending problems slow you down. Our guide offers 12 practical solutions to common issues, so you can achieve precise bends and quality results every time.A brake is a metalworking machine that allows the bending of sheet metal. A cornice brake only allows for simple bends and creases, while a box-and-pan brake also allows one to form box and pan shapes.

Sheet metal brakes help bend different metals. I this guide we review the best sheet metal breaks by brand, size, weight, cost and portability in a full online review. Bending is one of the most common sheet metal fabrication operations. Also known as press braking , flanging, die bending, folding and edging , this method is used to deform a material to an angular shape.

Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake.The process of stiffening sheet metal--known as cross braking--places a small bend across flat sections of metal. Each bend reduces the flat area of each side, increasing its overall strength. Increase the gap between the top and bottom dies of sheet metal brake by either pushing the clamping leaf handle away from the front of the brake or .A Cross Break in sheet metal is when multiple obtuse Bend Angles of approximately 170° are made across a flat section thin metal. Cross breaks are most commonly in an X shape, forming a slight pyramid shape in the metal without overly distorting it.#artfullyrogue #makingalivingasamaker #metalartistIf you do metal work, at some point you will need to bend sheet metal. And if you're not ready to invest in.

When stiffening ductwork or other sheet metal products, there are two primary techniques fabricators can employ, cross-braking or beading. Before we get into the specifics of how and when to perform each technique, let’s take a step back and ask the question, “Why should I stiffen my sheet, anyway?”This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending and material selection information.

Don't let sheet metal bending problems slow you down. Our guide offers 12 practical solutions to common issues, so you can achieve precise bends and quality results every time.

A brake is a metalworking machine that allows the bending of sheet metal. A cornice brake only allows for simple bends and creases, while a box-and-pan brake also allows one to form box and pan shapes.

types of bending sheet metal

step bending sheet metal

sheet metal cutting and bending

At Klassen's Metal Construction, we construct various metal buildings across Midland, Odessa, Big Spring & Lubbock, TX. Contact us to request a free estimate! Call Us for a Free Estimate .

breaking sheet metal|sheet metal bending diagram