3 axis cnc machining center quotes Order custom parts online. Upload your files for free instant quotes from CNC . Some laptops like the Legion 5 Pro has a plastic keyboard deck but a metal bottom panel, while others like the Helios 300 have a metal keyboard deck but a plastic bottom panel. Even then, the presence of just one metal panel can make the laptop much more solid.

0 · fathom cnc quotes

1 · custom cnc parts near me

2 · custom cnc machining near me

3 · cnc machining price list

4 · cnc machining factory

5 · cnc machining company

Most metals with magnetic properties are ferrous: metals and alloys that contain iron. These ferrous metals include mild steel, carbon steel, stainless steel, cast iron, and wrought iron.

fathom cnc quotes

Online CNC machining service for prototypes & production parts. Instant quotes for 1-1,000 units and tolerances to ±0.0008 inches.Order custom parts online. Upload your files for free instant quotes from CNC .

custom cnc parts near me

Instant CNC quotes for 1-1000 units. 1,000’s of 3-axis, 4-axis & 5-axis CNC mills. 50+ .

This provides us with a huge capacity for production and a wide range of .

Help center. EN. English . CNC machining materials. CNC machining in Mild steel. .

Vertical Mill machines with 5-axis rotary table, Dual axis turning center: .

Instant quotes for 1-1000 units. 100s of turning machines, Swiss lathes & multi .Our broad network of manufacturing partners includes over 240 stainless .

By following these best practices and techniques, you can help ensure that you're able to secure accurate and reliable quotes for 3-axis CNC turning centers that meet your specific needs and .

custom cnc machining near me

By following these best practices and techniques, you can help ensure that you're able to secure accurate and reliable quotes for 3-axis CNC turning centers that meet your specific needs and requirements.Online CNC machining service for prototypes & production parts. Instant quotes for 1-1,000 units and tolerances to ±0.0008 inches. Quotes for 25+ Manufacturing Processes. There are multiple factors influencing the cost of a CNC project. Design, quantity ordered and turnaround time can all affect the cost. For an accurate and fast quote, submit your details using Fathom’s SmartQuote platform. CNC manufacturing enables high accuracy, repeatability, control and precision. Most CNC machines are either 3- or 5-axis, and, in this article, we’ll look at their differences and what they’re each good for. A 3-axis CNC machine, such as a lathe, mill, or machine tool center, moves its tool (whether it’s a cutter, drill, or mill) along the X (left to right), Y (front to back), and Z (up and down) axes.

Need help finding the right machine? A Versatile Lineup of Vertical Machining Centers (VMC) - Whether you need a standard 3-axis mill, a powerful 5-axis machining center, or a small VMC for precision parts, there’s a Haas to do the work.Get an instant custom parts quote on our CNC Milling Services. 3, 4 and 5-axis machining capabilities. We produce your parts as fast as two days. Read more here.Find quality 3 axis cnc turning center quotes here. We're professional CNC Machining Products manufacturers and suppliers in China. Customized service and free sample are also offered in our factory.

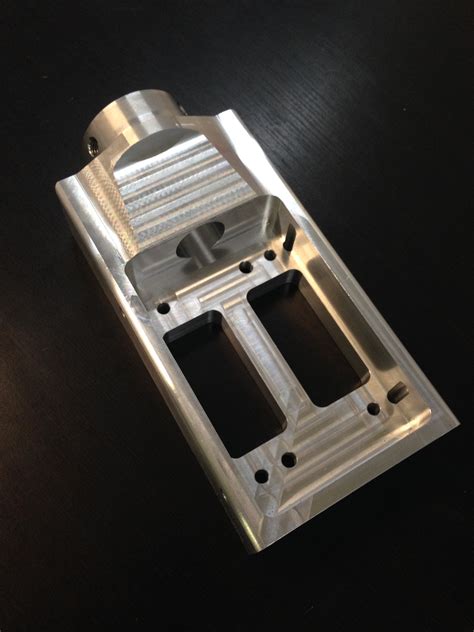

The 3-axis machining center is a foundational yet powerful configuration in CNC machining technology, controlling and machining on 3 linear axes: X, Y, and Z. This machine tool design is suited for a wide range of milling tasks, including flat milling, contour milling, and hole processing.

The main difference between 3-axis, 4-axis and 5-axis machining is the complexity of the movement both the workpiece and the cutting tool can move through, relative to each other. The more complex the motion of the two parts, the more complex the geometry of the final machined part can be.

V Series vertical machining centers are heavy-duty, box-way CNC mills built for tough applications such as roughing cast iron. These 3-axis machines feature belt or geared spindles to provide maximum torque. • Perfect combination of heavy cutting and high stability.By following these best practices and techniques, you can help ensure that you're able to secure accurate and reliable quotes for 3-axis CNC turning centers that meet your specific needs and requirements.Online CNC machining service for prototypes & production parts. Instant quotes for 1-1,000 units and tolerances to ±0.0008 inches. Quotes for 25+ Manufacturing Processes. There are multiple factors influencing the cost of a CNC project. Design, quantity ordered and turnaround time can all affect the cost. For an accurate and fast quote, submit your details using Fathom’s SmartQuote platform. CNC manufacturing enables high accuracy, repeatability, control and precision.

Most CNC machines are either 3- or 5-axis, and, in this article, we’ll look at their differences and what they’re each good for. A 3-axis CNC machine, such as a lathe, mill, or machine tool center, moves its tool (whether it’s a cutter, drill, or mill) along the X (left to right), Y (front to back), and Z (up and down) axes.Need help finding the right machine? A Versatile Lineup of Vertical Machining Centers (VMC) - Whether you need a standard 3-axis mill, a powerful 5-axis machining center, or a small VMC for precision parts, there’s a Haas to do the work.

Get an instant custom parts quote on our CNC Milling Services. 3, 4 and 5-axis machining capabilities. We produce your parts as fast as two days. Read more here.Find quality 3 axis cnc turning center quotes here. We're professional CNC Machining Products manufacturers and suppliers in China. Customized service and free sample are also offered in our factory.The 3-axis machining center is a foundational yet powerful configuration in CNC machining technology, controlling and machining on 3 linear axes: X, Y, and Z. This machine tool design is suited for a wide range of milling tasks, including flat milling, contour milling, and hole processing. The main difference between 3-axis, 4-axis and 5-axis machining is the complexity of the movement both the workpiece and the cutting tool can move through, relative to each other. The more complex the motion of the two parts, the more complex the geometry of the final machined part can be.

underwater junction box manufacturers

cnc machining price list

cnc machining factory

cnc machining company

In general, to drill a pilot hole for the #8 screw on softwood, you’ll need a 5/32-inch drill bit. For hardwood, use an 11/64-inch drill bit. However, the common drill bit size for the #8 screw is 1/8 inch. What are the Factors that I .

3 axis cnc machining center quotes|fathom cnc quotes