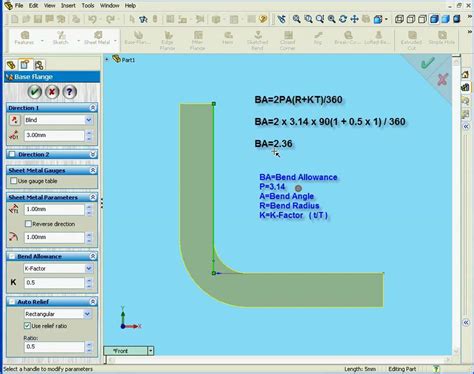

k factor and y factor in sheet metal K factor is a ratio between the distance from the neutral bend line to the inside bend radius and the material thickness. K factor uses the formula K factor = δ/T. Y factor uses the formula Y . Piutouyar 3 Inch Hollow Out Furniture Legs Set of 4, Black Artistic Metal Sofa Cabinet Legs, Modern Triangle Couch Feet Metal Furniture Legs Feet for Cabinet Cupboard Table Bookcase Wardrobe

0 · solidworks sheet metal k factor

1 · k factor sheet metal calculator

2 · k factor explained

3 · k factor bending sheet metal

4 · bending calculation for sheet metal

5 · bending allowance in sheet metal

6 · bend allowance k factor chart

7 · 304 stainless steel k factor

For the collectors of Pokémon trading cards, we present the True Steel Premium Collection Box. This extraordinary box includes a mix of sets like SM Team Up and XY Evolution, each containing English language cards.

K factor is a ratio between the distance from the neutral bend line to the inside bend radius and the material thickness. K factor uses the formula K factor = δ/T. Y factor uses the formula Y . Mathematically k factor value is equal to the ratio of position of the neutral axis and sheet thickness. In this article, we will discuss sheetmetal bend deduction, bend allowance, K . Effortlessly calculate K-Factor for sheet metal bending with our free online calculator. Save time and improve accuracy. Try it now!The Y and K-Factors affect how the part stretches when transitioning from a flat pattern to a finished piece so it is important to understand their values. However to achieve truly accurate .

The k-factor indicates the behaviour of the material being bent and how it reacts to the applied tensile and compressive stresses. In essence, it’s nothing more than the ratio of the sheet metal thickness to the neutral axis, i.e. .K-factor is a crucial parameter used in sheet metal bending calculations. It represents the location of the neutral axis in a bent sheet metal part. The neutral axis is the theoretical line within the .

The k-factor allows you to calculate the bend allowance, the outside setback, the bend deduction, and the flat layout of the precision part you’re forming. Defining the Neutral Axis. To understand the k-factor, you .The sheet metal k factor is a crucial parameter used during the bending and folding process of metal sheets. The degree of deformation of the metal sheet upon bending is indicated and .

solidworks sheet metal k factor

The K-Factor is used to calculate flat patterns because it is directly related to how much material is stretched during the bend. It’s used to determine Bend Allowances and Bend Deductions ahead of the first piece. It’s important to note that the Y-factor is not negative; rather, smaller positive values correspond to softer materials. The Y-factor is intimately related to the K-factor, another important constant in sheet metal bending. The .How to calculate bend allowance, K factor and Y coefficient in one click. To calculate the bend allowance, the K factor and the derived coefficient called the Y factor, insert the thickness and initial length of the sheet into the cells on the left.After bending the sheet, insert the inner radius, and flanges A and B. Bending angle is 90°.

Y factor and K factor represent part constants used in formulas to calculate the developed length of flat sheet metal required to make a bend of a specific radius and angle in a design. Y factor and K factor are defined by the location of the sheet metal .

The K factor is a key metric in many fields like statistics, engineering, and manufacturing. This article will explore what the K factor is, how it’s calculated, and its uses. It’s important for data analysts, electrical engineers, and sheet metal workers to know about the K factor. It helps them make better decisions and improve their work.Y factor and K factor represent part constants used in formulas to calculate the developed length of flat sheet metal required to make a bend of a specific radius and angle in a design. Y factor and K factor are defined by the location of the sheet metal . The biggest difference between the k-factor and the y-factor in sheet metal bending is that the y-factor takes the internal stresses of the material into account more so than the k-factor does. This means that calculations involving the y-factor are slightly more accurate than those involving k-factor, but also quite a bit more complicated and .Ok, I think I understand your goal now. Look up sheet metal design. This should tell you the bend deductions, bend factors and K factors that you need to understand the original length you need for the output required. It is all geometry and trig.

You can set Y factor and K factor to control the bend allowance of a sheet metal part using the following methods: . The material assigned to the part drives the Y factor, K factor, and bend table, which update when a new material is assigned to the part. So, now you have a formula for the BA—but where’s the k-factor? It’s hiding in that 0.0078 value, which is π/180 × k-factor. To arrive at 0.0078, the equation uses a k-factor of 0.4468, a commonly used factor that’s the default for many CAD systems.The K-Factor in sheet metal working is the ratio of the neutral axis to the material thickness. When metal is bent the top section is going to undergo compression and the bottom section will be stretched. The line where the transition from compression to stretching occurs is called the neutral axis. The location of the neutral axis varies and .

The k-factor is fundamental to designing precise sheet metal products. It allows you to anticipate the bend deduction for a large variety of angles without having to rely on a chart. While modern bend deduction charts now are reasonably accurate, historically bend calculation charts, both for bend allowances and bend deductions, were notorious . This example demonstrates how to apply the K-factor calculation formula to determine the K-factor for a specific sheet metal bending scenario. K Factor Chart. The following are K-factors for common metal materials. Soft copper or soft brass: K=0.35; Semi-hard copper or brass, mild steel, aluminium etc.: K=0.41K-factor is a crucial parameter used in sheet metal bending calculations. It represents the location of the neutral axis in a bent sheet metal part. The neutral axis is the theoretical line within the material thickness where neither compression nor tension occurs during bending.

The k-factor is fundamental in the press-bending sector and is closely linked to the concept of spring back. It is also known as bend allowance and serves to calculate the sheet metal layout. Knowing the k-factor formula is essential in order to bend any kind of sheet metal correctly; in fact, it varies according to the type of material to be deformed. .

This means that if you let Y equal .5, K will equal .318. The starting point for sheet metal design is usually around this number, so the default of Y is 5. Applying These Concepts. The K and Y factors are used to determine sheet metal bend .

The K-factor is the bending capacity of sheet metal, and by extension the forumulae used to calculate this. [1] [2] [3] Mathematically it is an engineering aspect of geometry. [4]Such is its intricacy in precision sheet metal bending [5] (with press brakes in particular) that its proper application in engineering has been termed an art. [4] [5]Start a new part > create a base flange > set the sheet metal parameters to whatever you want > delete the base flange feature and any sketches > save as part template > enjoy your new defaults Extra tip: K factor is a dimension that can be used in custom properties. The syntax is "D2@[email protected]". I have my templates set so . Use one of the listed K-Factor calculators and measurement of a sample bent part: K Factors Autodesk Inventor; Inventor K Factor Calculator; Manually calculate the K-Factor using the measure of sample sheet metal parts that were bent using the following formula:

You can set Y factor and K factor to control the bend allowance of a sheet metal part using the following methods: . The material assigned to the part drives the Y factor, K factor, and bend table, which update when a new material is assigned to the part.Hi I’m new to sheet metal design, can somone explain in simple terms what bend deduction, k factor is etc. and how it’s calculated? Guy who’s training me seems ignorant and rather than explain gave me a list of figures to use, he said use 4mm bend deduction for 2mm thickness, and 5.5 for 3mm thickness which is what we commonly use.

k factor sheet metal calculator

For example, if the K-factor is 0.318, the Y-factor would be calculated by multiplying 0.318 by pi, resulting in approximately 1.000, then dividing by two, yielding a Y-factor of 0.5. This Y-factor is then used in bend calculations to account for the material’s elastic behaviour during bending.

CATIA V5 is the metal bending software of choice across many industries. This tutorial covers how the K-Factor impacts metal bending and Learn how to calculate the K-factor in Sheet Metal Bending with this CATIA V5 tutorial.You can set Y factor and K factor to control the bend allowance of a sheet metal part using the following methods: . • Creating feature-specific bend allowance using the Bend Allowance tab of sheet metal tools when available. • Using the Miscellaneous . Discovering the material’s thickness, Mt, allows one to compute the K-factor for bending sheet metal. The K-factor may be calculated by dividing 180 by the product of BA and the ratio of Ir to Mt, and by the difference between the product of pi, Mt, and the corresponding bend angle. This formula may be written mathematically as:

It is typically derived using the formula Y-factor = (K-factor * π)/2 and is used in the bend allowance formula BA = (π/2 * (Bend angle/90) * (Ir + Mt * Y-factor)). Thoroughly understanding and applying the K-factor is fundamental for designing and producing precise sheet metal products, thereby ensuring fulfillment of design specifications .

conductive compound for electrical box

k factor explained

$16.99

k factor and y factor in sheet metal|bend allowance k factor chart