clearance for electrical junction boxes Many places definitely consider switchboards and panelboards to fall into that classification, but if you have a junction box and want to take voltage or current measurements in it - that sort of fits into that description, yet those area almost never required to comply with . Check out our plaque for wooden box selection for the very best in unique or .

0 · types of electrical junction boxes

1 · standard electrical junction box size

2 · pvc junction box size chart

3 · junction box sizing chart

4 · junction box size calculator

5 · electrical junction box size chart

6 · electrical junction box size calculator

7 · electrical box sizing chart

$98.00

2021 skybox metal universe box

types of electrical junction boxes

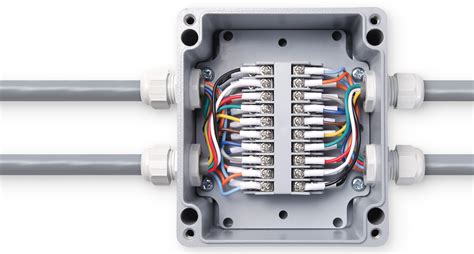

Many places definitely consider switchboards and panelboards to fall into that classification, but if you have a junction box and want to take voltage or current measurements in it - that sort of fits into that description, yet those area almost never required to comply with .Unused openings in boxes, raceways, auxiliary gutters, cabinets, equipment cases, or housings shall be effectively closed to afford protection substantially equivalent to the wall of the . Front clearance: There should be a minimum of 3 feet of clearance at the front of all electrical equipment, including panelboards, switches, breakers, starters, transformers, etc. Note that all panel doors and access doors must be .

standard electrical junction box size

As a general rule, you must maintain a minimum headroom clearance of 6 ft from the floor or platform up to any overhead obstruction. This workspace is mandatory and applies to service equipment, switchboards, .

Section 110.26 of the National Electrical Code outlines the criteria for the clearance area surrounding the junction boxes and other electrical components. According to Section 110.26(A), there must be a 36 inches depth and 30 . When working on electrical equipment in a passageway, be mindful of the potential for a fire alarm. If one occurs, you may need to secure equipment covers and clear the passageway of ladders, tools, and other items that .

No specific clearance is specified. A junction box does not meet the requirement of 110.26 IMO. Many places definitely consider switchboards and panelboards to fall into that classification, but if you have a junction box and want to take voltage or current measurements in it - that sort of fits into that description, yet those area almost never required to .

Section 110.26 specifies the requirements for the clearance area around electrical equipment, including junction boxes. Section 110.26(A) requires a clear space of at least 30 inches wide by 36 inches deep.Unused openings in boxes, raceways, auxiliary gutters, cabinets, equipment cases, or housings shall be effectively closed to afford protection substantially equivalent to the wall of the equipment.Front clearance: There should be a minimum of 3 feet of clearance at the front of all electrical equipment, including panelboards, switches, breakers, starters, transformers, etc. Note that all panel doors and access doors must be able to open a minimum of 90 degrees. As a general rule, you must maintain a minimum headroom clearance of 6 ft from the floor or platform up to any overhead obstruction. This workspace is mandatory and applies to service equipment, switchboards, panelboards, and motor control centers.

Section 110.26 of the National Electrical Code outlines the criteria for the clearance area surrounding the junction boxes and other electrical components. According to Section 110.26(A), there must be a 36 inches depth and 30 inches width of clear space. When working on electrical equipment in a passageway, be mindful of the potential for a fire alarm. If one occurs, you may need to secure equipment covers and clear the passageway of ladders, tools, and other items that impede egress by the occupants. No specific clearance is specified. A junction box does not meet the requirement of 110.26 IMO. You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull boxes, junction boxes, and conduit bodies per Sec. 314.28.

Working space for equipment operating at 600 volts, nominal, or less to ground and likely to require examination, adjustment, servicing, or maintenance while energized shall comply with the dimensions of 110.26 (A) (1), (A) (2), and (A) (3) . Many places definitely consider switchboards and panelboards to fall into that classification, but if you have a junction box and want to take voltage or current measurements in it - that sort of fits into that description, yet those area almost never required to . Section 110.26 specifies the requirements for the clearance area around electrical equipment, including junction boxes. Section 110.26(A) requires a clear space of at least 30 inches wide by 36 inches deep.Unused openings in boxes, raceways, auxiliary gutters, cabinets, equipment cases, or housings shall be effectively closed to afford protection substantially equivalent to the wall of the equipment.

Front clearance: There should be a minimum of 3 feet of clearance at the front of all electrical equipment, including panelboards, switches, breakers, starters, transformers, etc. Note that all panel doors and access doors must be able to open a minimum of 90 degrees.

As a general rule, you must maintain a minimum headroom clearance of 6 ft from the floor or platform up to any overhead obstruction. This workspace is mandatory and applies to service equipment, switchboards, panelboards, and motor control centers.Section 110.26 of the National Electrical Code outlines the criteria for the clearance area surrounding the junction boxes and other electrical components. According to Section 110.26(A), there must be a 36 inches depth and 30 inches width of clear space.

When working on electrical equipment in a passageway, be mindful of the potential for a fire alarm. If one occurs, you may need to secure equipment covers and clear the passageway of ladders, tools, and other items that impede egress by the occupants. No specific clearance is specified. A junction box does not meet the requirement of 110.26 IMO. You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull boxes, junction boxes, and conduit bodies per Sec. 314.28.

pvc junction box size chart

junction box sizing chart

2018 leaf metal perfect game all-american baseball sell sheet

2021 pro set metal football hobby box

Wisconsin Metal Fab, LLC is a contract manufacturer for a variety of industries. .

clearance for electrical junction boxes|junction box sizing chart