welding thin sheet metal tig Use thinner wire: Novice welders should understand that thinner wire needs to be used when MIG welding sheet metal. Thicker welding wire also means more heat which will result in you damaging the panel you are welding. A distribution box is a smaller, protective unit in electrical systems. It houses electrical connections and helps distribute power safely. Think of it as a compact version of a distribution board.

0 · welding thin stainless steel

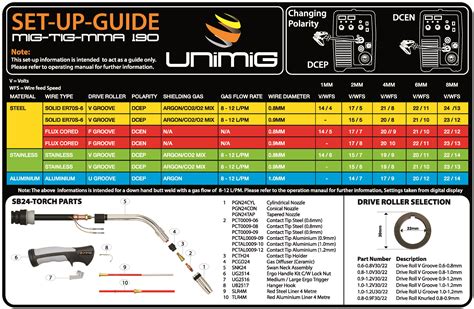

1 · welding sheet metal without warping

2 · unimig tig settings chart

3 · tig welding thin steel

4 · tig welding mild steel

5 · tig welding automotive sheet metal

6 · mig welding galvanized sheet metal

7 · 18 gauge weldable sheet metal

The FreshJet FJX Mechanical Air Distribution Box (ADB) is easy to use, simply twist a knob to set the temperature and fan speed to welcome refreshing air. State-of-the-art construction delivers superb front and back airflow allowing you to peacefully reset after a long day of exploration.

In this video I show how to set up and tig weld thin metal. There are a lot of different steps to take and I try to make it as easy as possible.

To weld sheet metal with solid wires, use electrode positive (EP, or reverse polarity). Don’t attempt to weld thin materials like sheet metal with flux-cored wires, which put . To weld thin metal, choose an appropriate process (TIG or MIG with low amperage), use a smaller diameter wire or filler rod, and adjust travel speed to prevent burn-through. Employ a pulsing technique, stitch welding, or .

What’s the Best Method of Welding Thin Metal? When it comes to welding slimmer metal sheets, MIG and TIG are the best option. The two work perfectly on nearly all material types. Nonetheless, if your aluminum or .

Use thinner wire: Novice welders should understand that thinner wire needs to be used when MIG welding sheet metal. Thicker welding wire also means more heat which will result in you damaging the panel you are welding. Practice Proper Technique. Proper technique is crucial when welding thin materials to achieve a high-quality weld without damaging the material. This includes maintaining a consistent arc length, controlling the . Did you know that TIG welding is the best option for sheet metal? The biggest problem any welder is going to face when it comes to sheet metal is the heat in.

The most important rules while welding thin stainless steel is to use the right welding techniques- that is using the right filler diameter, tungsten electrode, welding parameters along with shielding gas flow rate.TIG welding, also known as Gas Tungsten Arc Welding (), is a go-to welding process for professionals and hobbyists seeking clean, precise, and high-quality welds.Whether you're .Automation Types for Welding Thin Metal. Robotic TIG and MIG welding systems precisely control thin metals by adjusting heat, speed, and gas flow. Laser welding produces quality joints quickly and with little heat. It is ideal for thin metals. Spot welding automates sheet metal welding to ensure consistency without excessive heat spread. Conclusion

The filler metal is the material that melts into the weld and fills the gap between the two pieces being joined. MIG welding simplifies the feeding of filler metal, making the welder’s job easier. While the specific material may not . Sheet metal thickness suitable for welding typically ranges up to 1/4 inch using MIG or TIG welding, with TIG preferred for finer work on thinner metals. Which welding is best for thick metal? Stick welding or Flux-Cored Arc . When working with sheet metal, it’s important to consider the material’s thickness and composition. Thin sheet metals are highly susceptible to warping and burn-through if the welding settings are not properly dialed in. Achieving the perfect balance of amperage, voltage, tungsten size, and gas flow rate is the key to successful TIG welding on sheet metal. Hello everyone.It is not easy to weld thin sheet metal with a general welding machine.Therefore, there are many cases of using a cold welding machine when we.

In order to effectively TIG weld thin metal, it is important to use a low amperage setting on the welder. Typically, amperage is between 10 and 25 amps for thin materials like aluminum and stainless steel and between 20-35 amps for thicker materials like common steel. . When TIG welding sheet metal, the type, and size of filler rod you need . For thin sheet metal welding it can be 30 ampere while for thicker (e.g. 1/8” square groove weld)- it can go up to 220 ampere for example. GMAW-S gives low heat and makes it easy to use in all positions on sheet metal, low carbon steel, low alloy steel, and stainless steel sheet metal from 25 gauge (0.02 inch or 0.5 mm) to 12 gauge (0.1 inches or 2.6 mm).

welding thin stainless steel

When butt welding thin sheet steel, were do you strike the arc? . Tig welding thin metal. Thread starter Amit; Start date Apr 3, 2010; 1; 2; Next. 1 of 2 Go to page. Go. Next Last. A. Amit Member. Messages 89. Apr 3, 2010 #1 . Your going to need some mig or really thin tig fillter though. Soon as you arc up add some filler to stop it . Are you planning to weld auto body sheet metal or any thin metal with a MIG welder or tig welder? You should keep in mind some critical things to avoid creating any unwanted situations, and we have decided to incorporate them right here. . If you prefer to have more control, picking a pointed electrode might be a better idea for tig welders . For instance, TIG welding is excellent for thin metals and intricate work, while MIG welding is typically easier to learn and more versatile. . For sheet metal, TIG welding often provides the best results. I remember working on a vintage car restoration, where the sheet metal required a lot of detailed welding. After struggling with a MIG . Thin Materials: TIG welding excels in welding thin materials with precision. MIG welding is less effective for thin materials due to the potential for burn-through. . ensuring a clean and strong weld. Your Sheet Metal Fabrication —BOYI. At BOYI, we excel in transforming your sheet metal needs into precise, high-quality results.

cnc machining lamp part supplier

Thin materials, such as sheet metal or thin-walled tubing, present unique challenges when tig welding due to their thinness and sensitivity to heat. Welding thin materials require high precision and control to avoid warping or melting through the material.Pulsed TIG welding is an automatic feature that makes TIG welding thin metal a breeze. You set the frequency, and the current oscillates between the high and low amperage during the weld. . Although skill requirements are the highest among other welding methods, its advantages truly make TIG welding the king of sheet metal welding. MIG .

Skip Welding Technique. When welding thin sheet metal, do not try to run one bead right across the joint. This will cause too much heat to build up. Instead, run a series of short welds at different points in the metal that eventually join together. Leave the metal to cool for a second or two between welds to help the heat dissipate.

cnc machining in rhode island

welding sheet metal without warping

TIG welding thin sheet metal with a 3/32" (2.4mm) tungsten electrode. This might be obvious to you but for tig welding really thin metal, its best to taper the electrode like a needle for the best and most crisp arc starts. (less of a taper . How TIG welding sheet metal works. In TIG welding, material is supplied manually with the help of a bar or automatically with a spooled wire. This procedure is suitable for performing high quality welds in case of joining thin . About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .

For sheet metal what is the welding current needed. i see some machines with low of 15 amp, 20 amp 30 amp. . arc length etc where as stick and tig are constant current so when you set the current you know that is what you are getting. Best bet is to play about with the settings and see what works. . which will make welding thin sheet .

Skills – Because of the reasons listed above, MIG welding is generally an easier skill for most people to pick up, especially when welding on thin materials like sheet metal. TIG welding requires a bit more finesse, rhythm, and patience as you feed filler rod into a seam. Quality TIG welds, therefore, take more practice to perfect. Sheet metal welding is a process that seems relatively simple at first glance – connecting several metal parts with the help of high temperatures and filler material. However, there is a lot more to it than just this explanation, which is why this article would try to explain basic welding methods and offer several tips for sheet metal welding.Automation Types for Welding Thin Metal. Robotic TIG and MIG welding systems precisely control thin metals by adjusting heat, speed, and gas flow. Laser welding produces quality joints quickly and with little heat. It is ideal for thin metals. Spot welding automates sheet metal welding to ensure consistency without excessive heat spread. Conclusion

Subscribe to my channel for more weekly videos.https://goo.gl/T7d23ZVisit my store at https://weldmongerstore.com for TIG Fingers, DVDs, and other quality we.

Tig Welding Process for Thin Sheet Metal. If you are looking to master the art of Tig welding thin sheet metal, you need a solid understanding of the Tig welding process. Tig welding is a precise and controlled welding technique that uses a non-consumable tungsten electrode to heat and melt the metal, creating a strong and durable weld. Thin metal refers to any sheet metal that is less than 3/16 inch thick. This includes materials such as aluminum, stainless steel, and other common metals used in various industries. Welding thin metal requires a high level of precision and control to ensure the integrity and strength of the welded joint. . The most common processes for thin .

11. Sheet Metal Tips. As mentioned in the introduction, sheet metal work is a different animal than steel beams. Any of the above practices can be useful in mitigating distortion in sheet metal, but there are additional practices that can come into play and perhaps save the day. These include: Water-Cooled Jig Mig Welding Thin Sheet Metal. Mig welding is a popular and straightforward method of welding thin sheet metal. For mig welding, you don’t need much in the way of equipment. You will only need a mig welder and a proper technique for mig welding thin metal. If you are new to welding, start by welding with a low-amperage setting and a small wire . A 1.6mm tungsten is going to be your best bet on really thin sheet metal, but if you’re working on something closer to 3mm, you can use a 2.4mm tungsten. A small tungsten needs fewer amps to fully heat, and the lower the amps, the better. . TIG welding sheet metal can be done like TIG welding any other metal. Get your amps going, stick to a .

unimig tig settings chart

What is a Distribution Box? A distribution box is an exposed or concealed metal box that houses the circuit breakers that regulate the distribution of electricity throughout a building. This piece of equipment is also known as a distribution panel, distribution board, and circuit breaker panel.A septic distribution box, also known as a D-box, is a crucial component of a septic system. Its primary function is to receive the effluent (wastewater) from .

welding thin sheet metal tig|unimig tig settings chart