how to remove lap weld from sheet metal Lap welds are for quicky body shop jobs, overlapping metal is just an invitation for rust. However if two pieces of metal must be overlapped both sides of the seam should be protected from the elements either by paint, seam . If you need more room and have the space behind the range, you can install an adapter box which is a metal 4 square box that would mount over the single gang box, you .

0 · lap welding problems

1 · lap welding instructions

2 · lap welding auto sheet metal

3 · lap welding auto body sheet

4 · lap joint welding

5 · how to weld patches

6 · how to weld patch panels

7 · how to weld butt or lap

One of the best strategies for selecting good search sites is to get a current and a historic map of your town (or the city/town you plan to search) and to compare the two. Maps will indicate parks, trails, public land and all of the topography needed to .

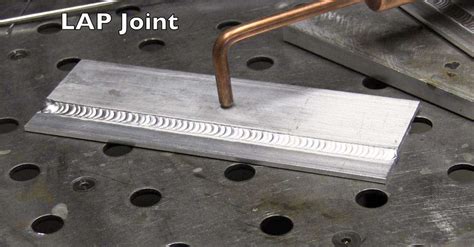

Lap welding auto body sheet metal with a MIG welder is made easy in the short video. Concentrates on tips that can help make your welding more robotic, neat and consistent. /. Lap welds are for quicky body shop jobs, overlapping metal is just an invitation for rust. However if two pieces of metal must be overlapped both sides of the seam should be protected from the elements either by paint, seam . When welding patch panels should you use a lap weld or a butt weld? Along with examples, and simple explanations, this video will help you make that decisio. To stick weld a lap joint, first set up your welding machine and supplies. Next, tack weld the two pieces of metal together at the edges of the overlap. Once the tack welds are in place, begin welding along the length of .

Using an angle grinder, remove the metal directly above the spot weld without burning through the panel. Once you have removed the majority of the first layer of metal, use ..99

Removing a weld is a common task for welders, especially for novices. You may need to remove a poor weld to fix your mistakes. You can melt the weld using a thermal method, such as a plasma cutter or a torch. You can . The first step is cutting away the damaged metal, then overlapping and clamping the new patch to the old fender, making sure it is accurately positioned. With the patch panel clamped in place, a scriber is used to mark .A common technique is to overlap and underlap the metal and then weld it (this is called a lap joint). The surface will be a little bit too high after you weld so you will tap it with a hammer and bend it down, then you will grind a bit off your weld. .

Each pull of the trigger will create an .062″ flange with a 45 degree flange that will give you flush lap joint when laying 20 or 18 gauge over top of the flange. On the flip side of . A lap joint is a type of joint where two pieces of sheet metal are overlapped and then welded together. It’s a popular choice for a variety of reasons – it’s relatively easy to execute, it provides a strong and durable . I'm trying to create an overlapping flange from two adjacet previosly created flanges. The purpose is to create a closed corner to a box and provide for a lap weld rather than edge weld. I can't seem to creat an offset such that the .

butt welding is the correct way to do it. you will be welding real metal so warping really shouldn't be an issue if you move around. do a couple practice pieces to get the settings right and find a comfort zone. it's only metal and any screw ups can be repaired if you don't warp the shit out of it. just take your time and you'll get the hang of it real quick. good helmut, good . As a rule, when MIG welding sheet metal, never use a body filler metal that is thicker than the base metal. It is recommended that a welder should use .023- or .024-inch wire for light gauge sheet metal work.

Deciding whether to butt weld or lap weld your automotive rust repair patch panels? This video will help make up your mind, end the debate and you'll know f.

TIG Welding Sheet Metal Lap Joints is a video about how I like to weld my sheet metal lap joints. It includes tacking, welding autogenious and with filler. . An easy explanation of how to plug weld auto body sheet metal and prevent the newly formed pinch weld from rusting between the layers of metal.https://www.yo. Welding the rusted sheet metal is one of the challenging tasks for welders. That’s why knowing how to weld sheet metal on a car is crucial. A wrong welding approach will make the sheet metal of car structurally weaker. Here, you will learn the best welding approach for sheet metals and how to achieve a better result.

lap welding problems

How To Weld Sheet Metal The RIGHT WAY - SUPER EASY#howto #diy #welding My Friend Pete shows us the easiest and simplest way to weld sheet metal. From butt w.

Today we will be going over some tricks to weld thin gauge sheet metal like body panels while avoiding wrapage. I go over 2 different techniques and several . While this roadster isn’t going to be a full out show car, Matt wants the patches to give the appearance of original sheet metal. Matt walks us through the process of blending the body lines at the wheel arch between the patch panel and the original line. The patch panel has a slightly larger body bead, which does not flow together well. For the non experienced a zero gap butt weld is not easy and even impossible at times. Just a 1/16 lap weld on a flange will be hard enough to get done nicely. REMEMBER you are NOT WELDING A BEAD on the panels. This will be 1/2 a million stitch welds for you. Weld a spot and move to the other side of the panel a spot is 1 tack BTW.

The lap joint is far easier to weld as there's a channel to weld in and there's two ply of metal to reduce burning through the panel. Sounds easy, right? Well, the drawbacks of a lap joint are that it leaves a channel here that can be susceptible to future rust and corrosion and be really hard to seal up.

Removing a weld is also sometimes necessary for salvaging parts. You may need to remove a weld to save one or more components from an assembly. You can remove welds using thermal or mechanical equipment. Thermal methods involve the use of high temperatures to liquefy the metal and undo the weld. Examples include plasma cutters and torches. #weldingtrick #stickwelding #6010Today I pass on a trick my Millwright friend Bruce gave to me. If your in a bind and need to weld a uneven or wide gap this . One guy sprayed Rhino-liner all around where the angle-iron contacts the sheet metal and 2 inches out on every side. I thought that was a good idea. Every springtime it would sweat between the sheet metal and the angle-iron and rust would spread out after a few years; and it would never be practical to weld solid on angle-iron to sheet metal. Be careful when grinding welds flat. I dont know what the guy used to weld or if its a butt joint or lap. If its a butt joint grinding it flat leaves virtually no strength if its the "average MIG weld". I have worked on lots of cars where just that has .

In today's video we discuss Butt Welding VS Overlapping Sheet Metal Panels on your project. Which should you be using? What the reasons you should be butt w. In this video I demonstrate how to set up your mig welder so you can weld thin sheet metal. We also showed in this video how to make your pattern, fit and we.

If you try to grind to perfection, you will start removing metal. This will result in a weaker joint. If the galvanization is thin, a knotted wire wheel can also remove most of the zinc without removing metal. Grinding doesn’t do a perfect job, but .

The weld often is used on sheet metal and makes the weld even stronger when you lay it on both sides. . You would need to remove excess metal on the bottom of the weld and could add more material on top to even it out. . The metal edge should be uniform and still intact after you lay the lap weld to it and the other piece of metal. A lap . Mig welding sheet metal is not all that difficult, especially if you have the extra thickness of a lap joint. Not sure how your mig is set up but you need to use gas rather that flux core wire. Thiner wire works better and if you practice on some scrap material of the same thickness you shouldn't have any trouble.

lap welding instructions

Welding sheet metal requires precision and expertise, . This step ensures that there will be no contaminants that could weaken the weld. Remove any rust: Use a wire brush or sandpaper to scrape off any rust from the metal surface. If there is extensive rusting, consider replacing the damaged parts. . Lap joint: Marine applications:

For thin sheet metal welding it can be 30 ampere while for thicker (e.g. 1/8” square groove weld)- it can go up to 220 ampere for example. GMAW-S gives low heat and makes it easy to use in all positions on sheet metal, low carbon steel, low alloy steel, and stainless steel sheet metal from 25 gauge (0.02 inch or 0.5 mm) to 12 gauge (0.1 inches or 2.6 mm).Welders never stick your welding rod again!stick welding (shielded metal arc welding - SMAW)watch full video https://youtu.be/0x8a24ysHU8Ky shows you this re.Use this amazon link to buy ANYTHING and it will throw some pennies in the jar toward Mike Fn Garage thanks for watchinghttps://amzn.to/2JPFrYh

Welding auto body sheet metal can present challenges for welders but Ron Covell is here to help mitigate warping with both MIG and TIG welding. . After you remove the majority of the weld, any low spots can be raised with careful hammer and dolly work, and then the entire area is sanded with a 50-grit disc on the grinder. Last, the panels can .Most of the light gauge sheet metal work will require the use of .023- or .24- inch while if you have a sheet metal having a gauge of more than 18-gauge then a .030-inch wire would be the most ideal. A ER70S-6 wire would be most ideal for welding mild steel.

What Size Drill Bit Should You Use to Make Pilot Holes? Drill bits are sized according to their diameter, which you may find engraved on their body or printed on their container or packaging. If you’re following directions or using .

how to remove lap weld from sheet metal|how to weld patch panels