classification of cnc machine tools based on motion type According to the function or type of CNC machining parts, CNC machining machine tools can be divided into five types: CNC milling machine, CNC lathe, CNC drilling . Many homeowners might wonder if it is safe and permissible to install a junction box in the attic. This article aims to provide a detailed answer to this question, exploring the considerations, precautions, and guidelines involved in installing a junction box in the attic.

0 · types of cnc machine tools

1 · servo controlled cnc tools

2 · point to point control cnc

3 · point to point cnc machine

By understanding the function of junction boxes, using the right tools and materials, following a step-by-step guide, and avoiding common mistakes, DIY enthusiasts can tackle wiring projects with confidence.

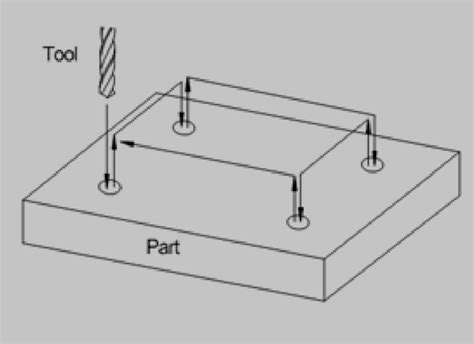

CNC machine tools can be divided into point position control, linear control and contour control according to the relative motion mode of tools and workpieces. 1. Point controlThere are many varieties and specifications of CNC machine tools, and the classification methods are also different. Generally, it can be classified according to the following four principles . According to the function or type of CNC machining parts, CNC machining machine tools can be divided into five types: CNC milling machine, CNC lathe, CNC drilling . There are many types of CNC machine tools available today, each with different structures and functions. They can generally be classified according to the following methods: 1. Classification based on the machine tool’s motion .

According to the functions or types of machined parts, CNC machines can be classified into five types: CNC milling machines, CNC lathes, CNC drilling machines, CNC plasma cutters, and CNC grinders.There are various types of CNC machine tools, and they can be classified based on function and structure using different methods. 1. Classification according to the control trajectory of .

12. Classification based on the motion type. Contouring Systems (Continuous Path Systems) It is used in CNC machine tools such as milling machines. These machines require simultaneous .This article discussed different types of CNC machine tools based on various classifications, explaining their functionalities, applications, limitations, and how they are used in manufacturing. It also touched on how to choose the most .

Generally speaking, the motion type such as, rapid, linear, and circular, the axes to move, the amount of motion, and the motion rate or means feed rate are programmable with almost all CNC machine tools.The types of CNC machining (CNC machines) can be classified according to a variety of differe principles. Let's take a look at four common categories of CNC machining, as well as the CNC machining processes and techniques involved . CNC machine tools can be divided into point position control, linear control and contour control according to the relative motion mode of tools and workpieces. 1. Point control

There are many varieties and specifications of CNC machine tools, and the classification methods are also different. Generally, it can be classified according to the following four principles based on function and structure. According to the function or type of CNC machining parts, CNC machining machine tools can be divided into five types: CNC milling machine, CNC lathe, CNC drilling machine, CNC plasma cutting machine and CNC grinder. There are many types of CNC machine tools available today, each with different structures and functions. They can generally be classified according to the following methods: 1. Classification based on the machine tool’s motion trajectory.

According to the functions or types of machined parts, CNC machines can be classified into five types: CNC milling machines, CNC lathes, CNC drilling machines, CNC plasma cutters, and CNC grinders.There are various types of CNC machine tools, and they can be classified based on function and structure using different methods. 1. Classification according to the control trajectory of machine tool motion

12. Classification based on the motion type. Contouring Systems (Continuous Path Systems) It is used in CNC machine tools such as milling machines. These machines require simultaneous control of axes. Contouring machines can also be used as point-to-point machines, but it will be uneconomical to use them unless the work

This article discussed different types of CNC machine tools based on various classifications, explaining their functionalities, applications, limitations, and how they are used in manufacturing. It also touched on how to choose the most suitable CNC . Generally speaking, the motion type such as, rapid, linear, and circular, the axes to move, the amount of motion, and the motion rate or means feed rate are programmable with almost all CNC machine tools.The types of CNC machining (CNC machines) can be classified according to a variety of differe principles. Let's take a look at four common categories of CNC machining, as well as the CNC machining processes and techniques involved in each category.

types of cnc machine tools

CNC machine tools can be divided into point position control, linear control and contour control according to the relative motion mode of tools and workpieces. 1. Point control

There are many varieties and specifications of CNC machine tools, and the classification methods are also different. Generally, it can be classified according to the following four principles based on function and structure. According to the function or type of CNC machining parts, CNC machining machine tools can be divided into five types: CNC milling machine, CNC lathe, CNC drilling machine, CNC plasma cutting machine and CNC grinder. There are many types of CNC machine tools available today, each with different structures and functions. They can generally be classified according to the following methods: 1. Classification based on the machine tool’s motion trajectory.

According to the functions or types of machined parts, CNC machines can be classified into five types: CNC milling machines, CNC lathes, CNC drilling machines, CNC plasma cutters, and CNC grinders.

There are various types of CNC machine tools, and they can be classified based on function and structure using different methods. 1. Classification according to the control trajectory of machine tool motion12. Classification based on the motion type. Contouring Systems (Continuous Path Systems) It is used in CNC machine tools such as milling machines. These machines require simultaneous control of axes. Contouring machines can also be used as point-to-point machines, but it will be uneconomical to use them unless the workThis article discussed different types of CNC machine tools based on various classifications, explaining their functionalities, applications, limitations, and how they are used in manufacturing. It also touched on how to choose the most suitable CNC . Generally speaking, the motion type such as, rapid, linear, and circular, the axes to move, the amount of motion, and the motion rate or means feed rate are programmable with almost all CNC machine tools.

servo controlled cnc tools

Learn how to properly wire terminal junction boxes for electrical connections. Understand the importance of proper wiring techniques, safety precautions, and troubleshooting tips for terminal junction boxes.

classification of cnc machine tools based on motion type|point to point control cnc