sheet metal design process At work we use Inventor because of its integration with Vault for file management and better management of large assemblies, but at home, for making 1-5 part assemblies I prefer Fusion 360. The sheet metal design process is nearly identical on both. I would try to go with Fusion, it’s cheaper and has a larger and more up to date tutorial .

$819.55

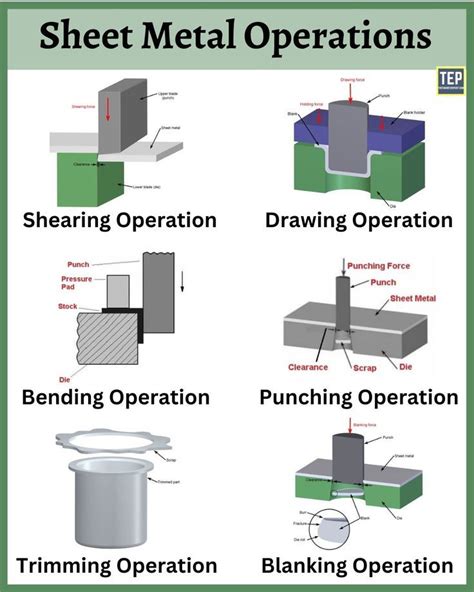

0 · various sheet metal processes

1 · types of sheet metal process

2 · types of sheet metal fabrication

3 · sheet metal working process pdf

4 · sheet metal process pdf

5 · sheet metal process in manufacturing

6 · sheet metal operations with diagrams

7 · sheet metal fabrication pdf

$2,400.00

Geomiq's Sheet Metal design guide helps you with your design process to accelerate production time and reduce production costs.

This must be accounted for in the design of the die and the bending process. Grinding in Sheet Metal Fabrication. Grinding is a finishing process used in sheet metal fabrication to smooth out surfaces, remove burrs and sharp edges, and prepare metal for further finishing treatments like painting or coating.Transferring Design to Metal: The precise measurements and patterns from the design phase are transferred onto the selected sheet metal. This is often done using computer-aided manufacturing (CAM) software, which ensures accuracy and minimizes the risk of errors.

Manufacturing Process: Becoming a Sheet Metal Design Pro!! Learn all the design considerations to be kept in mind while designing a manufacturable sheet metal part. Rating: . If you are planning to become a sheet metal designer or product design, then this is the right course for you. In this course, you will learn about design considerations .

In the manufacturing industry, the sheet metal process is common, and sheet metal parts are used in many different industries, including consumer products, appliances, aircraft, and the automotive and aerospace sectors. Sheet Metal Operations. Following are the 9 different types of sheet metal operations: Shearing Operations; Blanking OperationsAt work we use Inventor because of its integration with Vault for file management and better management of large assemblies, but at home, for making 1-5 part assemblies I prefer Fusion 360. The sheet metal design process is nearly identical on both. I would try to go with Fusion, it’s cheaper and has a larger and more up to date tutorial . Bending is a primary sheet metal forming process used to create shapes such as angles, channels, and enclosures. There are several bending techniques, including V-bending, U-bending, and air bending, each with its advantages and limitations. . A Comprehensive Guide for Sheet Metal Design - Sheet metal design is a specialized discipline within .

The design phase hugely affects the sheet metal industry’s complete manufacturing process. It considers manufacturability, cost-efficiency, and product quality, among other things. An optimized design ensures smooth transitions between different stages of production, such as cutting, bending, or welding.Sheet Metal Forming 2.810 D. Cooper !“Sheet Metal Forming” Ch. 16 Kalpakjian !“Design for Sheetmetal Working”, Ch. 9 Boothroyd, Dewhurst and Knight This is an overview of how to optimise sheet metal fabrication for cost reduction in design and production. It covers critical aspects such as material selection, cutting methods, bending techniques, welding, assembly, and prototyping. . Prototyping and testing are crucial phases in the design process, but they can also be costly if not .

We have created several sheet metal design resources for you. Take a look. Skip to content. Want to talk to a human? Our team is standing by! (603) 883 1510. Our Company Menu Toggle. . Say goodbye to the tedious process of designing basic sheet metal features from scratch. Our 3D tooling library empowers mechanical engineers and product . The red color in the die shown in Fig. 3 indicates 2D, dark red for rough machining, orange for controlled machining, purple for hole tapping, yellow for friction, and light green for precision surface machining. Inputs such as the type and dimensions of standard parts at the autonomous level, safety areas to check whether there is any crash and clearance with other .product development process from initial concept to product in operation. The SheetMetal Design User's Guide has been designed to show you how to design sheet metal parts of varying levels of complexity. Before reading this guide, you should be familiar with basic Version 5 . Sheet Metal Process - Rolling. Rolling tolerance pertains to the allowable variations during the rolling process, where sheet metal is passed through rollers to achieve specific thicknesses or shapes. The uniformity and consistency of the rolled sheet metal are critical and highly depends on the thickness of the material.

Vukota Boljanovic, Ph.D., has nearly 50 years of experience in applied engineering in the aircraft and automotive industries, as well as academia.He has performed extensive research in manufacturing engineering, including the impact of design and modification on sheet metal dies, jigs and fixtures, and process selection, aircraft assembly, and inspection tool and . A Step-by-Step Guide to the Design Process for Sheet Metal. It is common for individuals not to understand the fundamental procedures involved in manufacturing sheet metal. When essential information is lacking, it may be .

various sheet metal processes

AutoCAD Mechanical is revolutionizing sheet metal design by providing cutting-edge tools that improve both the speed and accuracy of the design process. From parametric design and automation features to enhanced . Sheet metal forming is a process used in many industries to make metal parts from thin metal sheets. It’s actually one of Xometry's most popular manufacturing methods. . and the complexity of the design, steel metal . In this article, we delve into essential tips for sheet metal design, exploring techniques to minimize errors and optimize processes. From blanking to bending, each step is crucial for achieving precise, cost-effective results. . Blanking is the process of separating sheet metal materials from each other by punching with a die. This stage is .Sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. The process typically uses coating, cutting, bending, and assembly techniques. Sheet metal is made from various materials, including steel, aluminum, zinc, and copper.

3-wat electrical junction box

AUTOMATION OF SHEET METAL COMB INATION DIE DESIGN PROCESS . Hussein M.A. Hussein 1, H ossam Salem 1, W alla Abdelzaher 1, V ishal Naranje 2, Morcos I. Ghobrial 1, Azza Barakat 1 . The process of computer-aided design and manufacturing of sheet metal parts starts with computer-aided design, goes through numerical simulation unfolding, nesting, cutting, stamping, bending, and other procedures, and ends with the computer automatically outputting the part’s process route, operation content, tooling motion trajectory (tool .

Design for manufacturability (DFM) is crucial in sheet metal design. By considering manufacturing constraints, tolerances, and processes during the design phase, designers can minimize the need for design changes, reduce production lead time, and ensure a .

4 11 16 electrical box

types of sheet metal process

Die design handbook: a practical reference book on process analysis, product design, metal movements, materials, and proved die designs for every class of sheet-metal pressworking Bookreader Item Preview remove-circle Share or Embed This Item. Share to Twitter. Share to Facebook. Share to Reddit. Share to Tumblr. Share to Pinterest . Sheet metal drawings are essential documents in the design and manufacturing process of sheet metal drawing technology. When drawing drawings, relevant standards and specifications should be followed to ensure the accuracy and readability of the drawings. Such features streamline the design process, enabling the creation of complex sheet metal components with accuracy. Onshape CAD Tool Utilizing feature-based modeling also aids in maintaining precision, as it creates a history of operations that can be edited, ensuring measurements are consistent and traceable.

Design Sheet Metal Parts with the Manufacturing Process in Mind In order to successfully manufacture a product made of sheet metal, it is important to have a detailed and accurate design. This eBook provides all the information you need to know about designing for sheet metal manufacturing, including best practices, tips and tricks, and common .

Manufacturing Integrated Design Sheet Metal Product and Process Innovation. . The book gives a systematic and detailed description of a new integrated product and process development approach for sheet metal manufacturing. Special attention is given to manufacturing that unites multidisciplinary competences of product design, material science .

types of sheet metal fabrication

Get the best deals for Vintage Metal Cash Box at eBay.com. We have a great online selection at the lowest prices with Fast & Free shipping on many items!

sheet metal design process|sheet metal fabrication pdf