sheet metal development Pattern Development: Sheet Metal Level 1. Triangulation When we looked at both parallel line and radial line pattern development, we saw fairly simple and limited layout process. We have conditions that must be met in order to use them. Triangulation is the process used when nothing else works. There are very few conditions in which . 5-axis machining represents a sophisticated CNC technology that enables simultaneous movement of cutting tools or workpieces along five distinct axes. This advanced capability allows the cutting tool to approach the workpiece from virtually any angle, facilitating the production of highly complex and precise components.

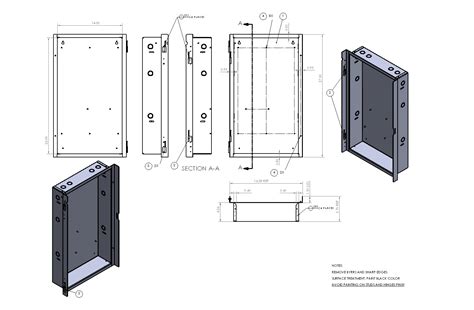

0 · sheet metal layout drawings

1 · sheet metal development calculator

2 · sheet metal design and fabrication

3 · sheet metal bending chart

4 · sheet metal basic design guidelines

5 · free sheet metal layout patterns

6 · free sheet metal layout books

7 · basics in sheet metal design

CAM software makes the CAD drawing/design into a code called G-code. The illustration shows what a bare-bones CNC machine might look like without its computer controller. See more

A sheet metal development serves to open up an object that has been rolled, folded, or a combination of both, and makes that object appear to be spread out on a plane or flat surface. .Sheet metal design is the process of engineering sheet metal into equipment, parts, assemblies, and products. Autodesk Fusion provides the necessary software to automate sheet metal .

Sheet Lightning -Sheet Metal Pattern Development Software. Sheet Metal Design and Unfolding Software for Tees, Bends, Junctions, Intersections, Cylinders, Cones, Ducts, Flue, Diverters, Adapters, Chutes, Chimneys, Hoppers, Structural Steel and much more. See specification for details. Download SHEET LIGHTNING Pro v6 Demo (Latest)

honeywell 6104 fire resistant steel security safe box

Pattern Development: Sheet Metal Level 1. Triangulation When we looked at both parallel line and radial line pattern development, we saw fairly simple and limited layout process. We have conditions that must be met in order to use them. Triangulation is the process used when nothing else works. There are very few conditions in which .Study with Quizlet and memorize flashcards containing terms like All lines must radiate from a common _____ for radial line development to be used, Radial line development on some objects is faster than triangulation, Radial Line development is use for _____ patters and more. I did my own research and found out that in a machine for flattening sheet metal or strip metal, comprising double screws, which serve to axially adjust a yoke, which carries upper rolls, and which screws are adjustable jointly or in pairs by means of nuts threaded on the screws and connected to respective worm wheels, this object is accomplished in that the nuts are . Sheet Metal Development Technician/Level 2: .00 - .50/hour Sheet Metal Development Technician/Level 3: .00 - .00/hour. Your actual level and base salary will be determined on a case-by-case basis and may vary based on the following considerations: job-related knowledge and skills, education, and experience.

Sheet metal development Thread starter eski1; Start date Mar 4, 2006; Status Not open for further replies. Mar 4, 2006 #1 eski1 Mechanical. Jun 15, 2004 90 GB. Hello Is there a sheet metal development tool for working out the flat sheet size for autocad I currently use Autocad 2002LT Cheers

sheet metal layout drawings

Sheet Metal Development Technician/Level 2: .00 - .50/hour Sheet Metal Development Technician/Level 3: .00 - .00/hour . Your actual level and base salary will be determined on a case-by-case basis and may vary based on the following considerations: job-related knowledge and skills, education, and experience. The Development of a Prototype. After creating a sheet metal design model, engineers go through several operations to preserve the component’s geometric integrity. . Bending the metal sheets is what this process is all about, as the name suggests. Sheet metal is bent by metal fabricators utilizing a variety of machinery and tools, including .

Mathis Development Group is a mechanical contractor company that is well diverse in many specialized fields of new construction development. . Since 1986, Jackson Sheet Metal has been a trusted expert in providing high-quality sheet metal fabrication and welding services.Image 5 of The universal sheet metal pattern cutter; a comprehensive treatise on all branches of . The Universal Sheet Metal Pattern Cutter A COMPREHENSIVE TREATISE ON ALL BRANCHES OF SHEET METAL PATTERN DEVELOPMENT Volume II ARCHITECTURAL SHEET METAL WORK Including Drawing, (Full Size) Detailing and Lettering, Development and.

EasyBlank Cloud Service is free of charge and can be used directly from the browser without having to install the software. The results are provided within the browser and can be accessed in IGS CAD format accompanied by a detailed report in Excel format.

22 Frustum of a Cone . Draw an elevation view, including the apex point.; Profile the base of the elevation view and divide it into 6 equal parts.; Label the profile from 1 to 7 and project the divisions vertically into the base of the cone. Project the element lines from the base to the apex of the cone.; Locate a radius point where you want to develop the pattern.Pattern Development: Sheet Metal Level 1. Introduction When wanting to build a project, we need to first imagine it. The process of pattern development gives us the ability to take that visual representation and actually create the object. It allows us to turn two-dimensional metal, into three-dimensional objects, which is the basis for .

Pattern Development: Sheet Metal Level 1 by Brian Coey is licensed under a CC BY 4.0 Licence. If you redistribute all or part of this book, it is recommended the following statement be added to the copyright page so readers can access the original book at no cost:

Learn more about sheet metal design software resources, products, and tutorials. NEW - Professional Fusion Trial: Get 30-day free access to advanced . and fabricate in a single integrated product development tool. Try Fusion for free. .20 Right Cone . Draw an elevation view.; Profile the base of the elevation view and divide it into six equal parts (see Divide a Circle Into 12 Equal Parts).; Label the profile from 1 to 7 and project the divisions vertically into the base of the . In order to create the sheet-metal development of the cylindrical elbow, and due to the difficulty in programming Visual Basic directly in the CATIA “Drafting” module, the “Part Design” module has been used to first program .

Sheet Metal Development Technician/Level 3: .00 - .00/hour . Your actual level and base salary will be determined on a case-by-case basis and may vary based on the following considerations: job-related knowledge and skills, education, and experience. Discover the top 5 free CAD software for sheet metal design, including FreeCAD, Onshape, and Fusion 360. Unleash your creativity with these powerful, easy-to-use programs that streamline your sheet metal projects. . You can actively contribute to the development and find a great community. If you are a maker and love to support Open-Source .

hooking pvc to electric box

Deep drawing is one of the primary methods used to create complex three-dimensional shapes from sheet metal. The process involves pulling the metal into a die using a punch, forming it into a desired shape. Material stretchability: Ensure the metal can stretch adequately to conform to deep-drawn shapes. Materials like aluminum and cold-rolled .Development Radius (R1 and R2) : Development Radius has calculated this calculator and Denoted By R1 and R2 for Inner and Outer Radius respectively. This development Radius is used to layout cone fabrication layout markings or Flat Pattern Markings. Refer to Standard Image for understanding these dimensions at Output sections. Development Angle . Our comprehensive online sheet metal bending calculator is an essential tool for precision metalworking, enabling you to swiftly and accurately determine critical parameters for sheet metal bending operations. This advanced calculator provides key insights into: Unfolded flat size: The total length of the sheet metal when flattenedUse the elbow rule (# of pcs × 2 − 2) to find the number of gores.For our example, it is 4 × 2 − 2 = 6.Each end piece is made up of 1 gore and each middle piece is made up of two gores.; Use the angle of the elbow divided by the number of gores to find the miter angle. In our case, 90° ÷ 6 = 15°. Now that we know the miter angle is 15°, we can use an end gore and lay it out similar .

Feb 9, 2022 - Explore Chris's board "Sheet Metal Development" on Pinterest. See more ideas about sheet metal, sheet metal fabrication, sheet metal work. These software provide sheet metal modules or related functions that can help designers with the design and unfolding calculations of sheet metal parts. Use the sheet metal module or tools in the software: Most 3D CAD software provides related tools and functions for sheet metal design. For example, Creo offers a variety of methods for .

sheet metal development calculator

sheet metal design and fabrication

Sheet Metal Development Calculator (Free; Google Play 4.1 out of 5 stars) This simple app utilizes excellent visuals that help calculate the development of a huge range of sheet metal parts. Weight Calculator for Metals (Free + in-app purchases); Google Play 4.6 out of 5 stars; iTunes 4.3 out of 5)1 Sheet Metal Development. 2 . 3 Fold The location for a bend in the metal - 4 Hem A fold along the edge of the metal to strengthen the edge and to give it smooth edges - 5 Layout Transferring the size and shape .

homemade aluminum boat fabrication tuscaloosa alabama

sheet metal bending chart

Explore the comprehensive guide to sheet metal fabrication with Shengen, the B2B manufacturer. Uncover techniques, trends, and applications.

sheet metal development|sheet metal basic design guidelines