what wire to use welding automotive sheet metal Automotive Sheet Metal Parts. Welding is commonly used to join together sheet metal parts in the automotive industry. These parts include brackets, hinges, spring seats, caps, covers, etc. . Work with Small Diameter .

Find Weatherproof electrical boxes at Lowe's today. Shop electrical boxes and a variety of electrical products online at Lowes.com.

0 · which mig wire for sheet metal

1 · which mig wire for auto body sheet

2 · welding wires for sheet metal

3 · welding sheet metal

4 · welding auto sheet metal

5 · welding aluminum sheet metal

6 · how to weld sheet metal

7 · how to weld auto body sheet metal

Metal Sheets. Metal Angles. Metal Tubes. Metal Bars. Metal Channels Sort by. Most Popular. Pickup & Delivery. Category. Brand Price Finish Gauge All filters. 253 items in Metal Sheets, Bars, & Rods. Hillman SteelWorks 12 in. x 24 in. #16 Weldable Solid Steel Sheet. 5 (6) | Item # 350590299. Pickup Today. FREE. Same Day Delivery. Standard .

air return box sheet metal

which mig wire for sheet metal

Are you planning to weld auto body sheet metal or any thin metal with a MIG welder or tig welder? You should keep in mind some critical things to avoid creating any unwanted situations, and we have decided to incorporate them right here. See more Once clamped, the panels are tack welded together, spacing the tacks no more than 1 inch apart. Every welder has their own preferences for sheet metal. I’m using 0.023-inch . I welded up some sheet metal with my new to me MM250 with the standard .035 wire. The tack, tack, tack method worked great for me and can be fast once you get into it. .

which mig wire for auto body sheet

Learn how to MIG weld automotive sheet metal in about 5 minutes or less! I keep it short and to the point in this welding instructional video and show how very easy it is to start .

Today we will be going over some tricks to weld thin gauge sheet metal like body panels while avoiding wrapage. I go over 2 different techniques and several . Automotive Sheet Metal Parts. Welding is commonly used to join together sheet metal parts in the automotive industry. These parts include brackets, hinges, spring seats, caps, covers, etc. . Work with Small Diameter .

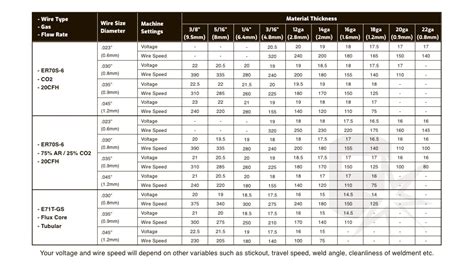

When MIG welding automotive sheet metal, thin wire is better. Most often .023 solid wire is used with a 25/75 (argon/CO2) shielding gas. Some welders can not use .023 wire, so .030 wire can also be used instead but . I have had good luck with both the .025 and .030 wire, but I have found myself in rare situations where the .030 was just a little too hot. I use the same 75/25 mix. If you have access to the back of your weld, pick up a copper spoon or two. I picked up a couple from Harbor Freight, and they have really been nice to have when welding sheet.

Today we will be going over some tricks to weld thin gauge sheet metal like body panels while avoiding wrapage. I go over 2 different techniques and several . Enter the world of Flux Core Welding (FCW), a versatile technique with a unique approach to fusing materials.This method revolutionizes how welders approach sheet metal, from automotive repairs to constructing metal artworks.Grasping the principles of Flux Core Welding is essential for anyone interested in mastering this skill to achieve strong, durable, and reliable . Get some scrap sheet metal the gauge you are going to weld and practice. I've welded automotive sheet metal for years with .035 wire in my Millermatic 250 and never had a problem. Sheet metal that gauge should be welded with tacks spaced 3/4"-1" apart then let cool. Never try to run a straight bead. It will warp too much.Wire feed welding, also known as MIG (Metal Inert Gas) welding, involves the use of a wire that is fed continuously at a pre-set speed. This wire acts as both the electrode and the filler material, melting to form the weld as an inert gas shields it.

I also have a spool of Inefil, made in Italy. I use .023 since it is mostly automotive sheet metal I’m welding on. Occasionally I’ll do thicker material and really have to turn up the wire speed. Never had a problem. . E70S-2 welding wire is made up of the following chemical elements: Carbon: 0.05–0.07% ; Manganese: 0.90–1.40% . However, getting the MIG welder’s settings just right is key to a successful weld. For filler metal selection, the electrodes in the ER4xxx and ER5xxx are most suitable for welding auto body panels. The panels’ aluminum’s chemical properties also require high voltage and wire feed speed settings to match the appropriate mode of metal . Learn how to MIG weld automotive sheet metal in about 5 minutes or less! I keep it short and to the point in this welding instructional video and show how v.During the latter, the wires use more heat as the arc also has to burn the flux inside the welding wire. Basically, MIG welding is much better at managing heat during welding, which leads to fewer holes and warping. You have to use the smallest wire possible for the job, smaller wires use less heat to melt. For welding on materials that are .

These wires are solid-gas metal arc welding wire, composite GMAW wire, and flux-cored wires. Each of the wires offers its own set of benefits and also possesses unique drawbacks. For sheet metal welding, welders will typically support flux-cored wires or solid wires as these give you the most control and versatility. Before initiating the plug welding sheet metal process, it's imperative to prepare the sheet metal to ensure optimal weld quality and structural integrity. . This method is commonly used in automotive and sheet metal fabrication, providing a clean and unobtrusive finish. By comprehending the principles of plug welding, you will be equipped to .Yes, flux core welding can be used to weld car sheet metal. It is a wire welding process that uses a consumable electrode wire and a self-shielding flux to provide greater control over heat and penetration. Imagine a welding process that minimizes distortion, enhances precision, and improves efficiency. Laser welding technology for sheet metal does exactly that, revolutionizing industries from automotive to high-tech .

When you MIG weld any metal sheet, you must look at and care for two things. Burning through the sheet itself. Warping of the sheet, especially the edges; Creating excess heat and burning through one part of the sheet is easy. Even .

Instead, everything you need to deposit a weld comes from a spool of metal wire. In this welding process, more popularly known as MIG, a gas tank (typically CO2 or argon) provides the shielding while the wire melts into the . You don't need TIG for sheet metal; you just need the right settings and a lesson—like all of us do. Most auto body shops don't use TIG for panels; they use MIG, and that says a lot. Your machine can work fine, with a few operator tricks. The biggest mistakes with sheet metal welding are gap and heat. Flux core is way harder to do on thin metal.

The age-old mantra “everything is unique” may seem cliche, but dismissing this statement can mean trouble, especially when you’re trying to weld sheet metal with flux core. When welding sheet metal using flux core, everything can be a bit messy. Aside from splattering, there’s also the risk of warping, melt-through, and even holes. For thinner gauge sheet metal like 18 or 20 gauge we suggest .023 (6mm) wire in your MIG welder. Keep the Stick Out Short-Stickout of your MIG wire is important when welding any type of metal, but especially sheet metal. Holding the tip too far from the surface will cause the wire to have to come out too far to touch the metal. This means the . Can the Titanium Easy-Flux 125 Flux Core Welder be used for Auto Body Repair? Lap, butt and plug welds are demonstrated on 22 gauge (.030") auto body sheet . Automotive sheetmetal and structural welding are vast topics, and it is not possible to give them anything approaching complete coverage here. This article concentrates on some of the fundamentals of welding sheetmetal sections, and on a few ploys that that may make this type of welding easier for you to perform, while producing superior results. [.]

Stay away from the flux core wire for body panel replacement. You want the filler rod wire(gas sheilded). I've used L-56 .025-.035 wire for welding sheet metal with a Lincoln welder. Good luck, and pratice a little bit before tackeling the job. In this video I demonstrate how to set up your mig welder so you can weld thin sheet metal. We also showed in this video how to make your pattern, fit and we.

welding wires for sheet metal

I recently bought a Millermatic 212 Autoset 160 amp welder for my toy box. I use .030 wire and leave it set on auto. The dial is marked in the thickness of the gauge of the metal being welded with a separate dial for the thickness of the wire that you are using, and automatically sets the amperage of the weld, and will change during the weld as necessary.

welding sheet metal

The welding of sheet metal requires the use of a wire or a tig welder. This is probably the most efficient way to weld auto body panels. . However, if you don’t have a wire, you can use a TIG welder for auto bodywork. Stick welding requires you to place a stick of wire between two plates, a point of which touches the metal. That is a little .MIG welding stands for "Metal- Inert Gas." By definition MIG requires a bottle of inert shielding gas, often 25% CO2 and 75% Argon. This is ideal for things like auto body tnin sheet metal. Although a seperate shield gas is often used industrially for flux core welding. Some wire types don't need an external shield.

air conditioning junction box

aia sheet metal

$9.99

what wire to use welding automotive sheet metal|how to weld auto body sheet metal