cnc lathe machining chamfers Chamfer programming on CNC lathes is crucial for achieving precision and quality in machining operations. By understanding the definition, purpose, and benefits of chamfers, operators can optimize their CNC lathe operations. A junction box is not a special type of box but any standard electrical box used to enclose wire splices. The most commonly used box for junctions is a 4-inch square box (either .

0 · lathe chamfer directions

1 · lathe chamfer control

2 · cnc lathe chamfer diagram

3 · cnc lathe chamfer code

4 · cnc lathe chamfer

5 · cnc chamfer programming

6 · chamfering machine

7 · chamfer programming on cnc lathe

$139.99

Chamfer programming on CNC lathes is crucial for achieving precision and quality in machining operations. By understanding the definition, purpose, and benefits of chamfers, operators can optimize their CNC lathe operations.

Can anyone point a noob to some info on how to manually program a lathe for chamfers and radii? What I currently do for chamfers is guesstimate the X Z. Learn all about a chamfers including different ways to measure them and how they compare to similar features.CNC programming example code to demonstrate, how to program a Chamfer and Radius (Corner Rounding) with G01 G-code. Easy to program and understand . Chamfers for Lathes. With Lathes, putting a chamfer on an edge is simple and doesn’t require special tooling. It’s just part of the profile that needs to be cut. Since the operation is so common, many CNC Lathes have a built-in .

This month’s video from Marc from G-Code Tutor take a fresh look at the fundamentals of chamfering on both manual and CNC lathes. Chamfers are a key feature in . Chamfers can be programmed on a CNC lathe using G-code, which is a programming language used to control CNC machines. To program a chamfer on a CNC lathe, you need to use the G01 command, which is used to .

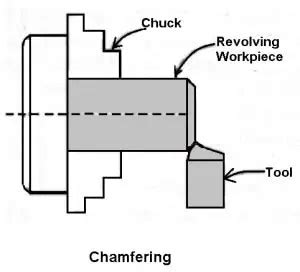

Chamfering is the process in developing that edge and what one could argue, a unique yet very common application. A chamfer edge is made up of a flat edge meeting a 45-degree angle. A chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance.Chamfer programming on CNC lathes is crucial for achieving precision and quality in machining operations. By understanding the definition, purpose, and benefits of chamfers, operators can optimize their CNC lathe operations.

Can anyone point a noob to some info on how to manually program a lathe for chamfers and radii? What I currently do for chamfers is guesstimate the X Z.

Learn all about a chamfers including different ways to measure them and how they compare to similar features.CNC programming example code to demonstrate, how to program a Chamfer and Radius (Corner Rounding) with G01 G-code. Easy to program and understand that even a beginner level CNC machinist can understand and program such sample codes. Mostly works on Fanuc and similar CNC controls. No extra G-code or technique is required. Chamfers for Lathes. With Lathes, putting a chamfer on an edge is simple and doesn’t require special tooling. It’s just part of the profile that needs to be cut. Since the operation is so common, many CNC Lathes have a built-in capability to do chamfering and corner rounding (filleting) of edges.

This month’s video from Marc from G-Code Tutor take a fresh look at the fundamentals of chamfering on both manual and CNC lathes. Chamfers are a key feature in machining, essential for removing sharp edges and facilitating part assembly. Chamfers can be programmed on a CNC lathe using G-code, which is a programming language used to control CNC machines. To program a chamfer on a CNC lathe, you need to use the G01 command, which is used to make a linear movement.Chamfer milling operations made easy: Chamfers V-cuts undercuts preparation for welding deburring operations along the workpiece edges. Read our tips!Many people feel that manual programming of CNC lathes is cumbersome when encountering arcs, chamfering, and calculating point coordinates. Today's article shares two knowledge points, which will save you worry and effort in programming.

Chamfering is the process in developing that edge and what one could argue, a unique yet very common application. A chamfer edge is made up of a flat edge meeting a 45-degree angle. A chamfer edge improves visual properties, but it is also a practical option for reasons other than appearance.Chamfer programming on CNC lathes is crucial for achieving precision and quality in machining operations. By understanding the definition, purpose, and benefits of chamfers, operators can optimize their CNC lathe operations. Can anyone point a noob to some info on how to manually program a lathe for chamfers and radii? What I currently do for chamfers is guesstimate the X Z. Learn all about a chamfers including different ways to measure them and how they compare to similar features.

CNC programming example code to demonstrate, how to program a Chamfer and Radius (Corner Rounding) with G01 G-code. Easy to program and understand that even a beginner level CNC machinist can understand and program such sample codes. Mostly works on Fanuc and similar CNC controls. No extra G-code or technique is required. Chamfers for Lathes. With Lathes, putting a chamfer on an edge is simple and doesn’t require special tooling. It’s just part of the profile that needs to be cut. Since the operation is so common, many CNC Lathes have a built-in capability to do chamfering and corner rounding (filleting) of edges.

This month’s video from Marc from G-Code Tutor take a fresh look at the fundamentals of chamfering on both manual and CNC lathes. Chamfers are a key feature in machining, essential for removing sharp edges and facilitating part assembly. Chamfers can be programmed on a CNC lathe using G-code, which is a programming language used to control CNC machines. To program a chamfer on a CNC lathe, you need to use the G01 command, which is used to make a linear movement.Chamfer milling operations made easy: Chamfers V-cuts undercuts preparation for welding deburring operations along the workpiece edges. Read our tips!

lathe chamfer directions

ul junction box

A metal roof can enhance the modern appeal of a contemporary brick house or add a sleek contrast to a more traditional structure. The combination of the rich textures of brick .

cnc lathe machining chamfers|cnc lathe chamfer