a straight fin fabricated from 2024 aluminum alloy k 185 Solution: Consider the diagram showing straight fins of rectangular, triangular, and parabolic profiles. Calculate the fin parameter, m. Here, h is the heat transfer coefficient, k is the thermal . One of the most significant benefits of a stainless steel lunch box is its insulation properties. Unlike plastic containers, which are not able to keep your food warm or cold for very long, a stainless steel lunch box is able to maintain the temperature of your food for several hours.

0 · straight fin diagram

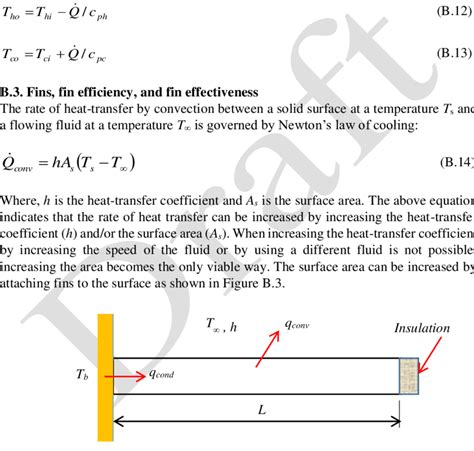

1 · aluminum straight fin diagram

Resources - ISO Certified Industrial Sheet Metal Fabrication | HUI Mfg.

A straight fin fabricated from 2024 aluminum alloy (k = 185 W/m?K) has a base thickness of t = 3 mm and a length of L = 15 mm. Its base temperature is Tb = 100 C, and it is exposed to a fluid .Solution: Consider the diagram showing straight fins of rectangular, triangular, .A straight fin fabricated from 2024 aluminum alloy (k-185 W/m- K) has a base .

how to connect electrical junction box

The fin is made of an alloyed aluminium with k=180 W/(m⋅K). The convection coefficient =100 W/(m 2K). Find the temperature at the end of the fin, the heat loss from the fin, .Solution: Consider the diagram showing straight fins of rectangular, triangular, and parabolic profiles. Calculate the fin parameter, m. Here, h is the heat transfer coefficient, k is the thermal .A straight fin fabricated from 2024 aluminum alloy (k-185 W/m- K) has a base thickness of-3 mm and a length of L- 15 mm. Its base temperature is To-100°C, and įt is exposed to a fluid for which T-20°C and h-S0 wmr . A straight fin fabricated from 2024 aluminum alloy (thermal conductivity = 185 W/m*K) has a base thickness of 3 mm and a length of 15 mm. Its base temperature is 100°C, .

A straight fin fabricated from 2024 aluminum alloy (k=185 W/m-K) has a base thickness of t=15 mm and a length of L=75 mm. Its base temperature is T=100°C, and it is .

A straight fin fabricated from 2024 aluminum alloy (k = 185 W/m ∙ K) has a base thickness of t = 3 mm and a length of L = 15 mm. Its base temperature is Tb = 100°C, and it is . A strait fin fabricated from 2024 AL with k=185w/mK base thickness=3mm, length=15mm. Tb=100C and fluid temp is Tinfinity=20C and h =50 w/m^2K. For the foregoing .K) has a base thickness of t = 3 mm and a length of L=15 mm. Its base temperature is Tb =100 ºC, and it is exposed to a fluid for which T = 20 ºC and h = 50 W/m2 K.

A straight fin fabricated from 2024 aluminum alloy (k = 185 W/m?K) has a base thickness of t = 3 mm and a length of L = 15 mm. Its base temperature is Tb = 100 C, and it is exposed to a fluid for which T? = 20 C and h = 50 W/m2?K. The fin is made of an alloyed aluminium with k=180 W/(m⋅K). The convection coefficient =100 W/(m 2K). Find the temperature at the end of the fin, the heat loss from the fin, and the fin effectiveness. The fin is made of an alloyed aluminium with k=180 W/(m⋅K). The convection coefficient =100 W/(m 2K). Find the temperature at the end of the fin, the heat loss from the fin, and the fin effectiveness.Solution: Consider the diagram showing straight fins of rectangular, triangular, and parabolic profiles. Calculate the fin parameter, m. Here, h is the heat transfer coefficient, k is the thermal conductivity, and t is the base thickness.

A straight fin fabricated from 2024 aluminum alloy (k-185 W/m- K) has a base thickness of-3 mm and a length of L- 15 mm. Its base temperature is To-100°C, and įt is exposed to a fluid for which T-20°C and h-S0 wmr .

A straight fin fabricated from 2024 aluminum alloy (thermal conductivity = 185 W/m*K) has a base thickness of 3 mm and a length of 15 mm. Its base temperature is 100°C, and it is exposed to a fluid with T[infinity] = 20°C and a convective heat transfer coefficient of . A straight fin fabricated from 2024 aluminum alloy (k=185 W/m-K) has a base thickness of t=15 mm and a length of L=75 mm. Its base temperature is T=100°C, and it is exposed to a fluid for which T=20°C and h=100 W/m^2 A straight fin fabricated from 2024 aluminum alloy (k = 185 W/m ∙ K) has a base thickness of t = 3 mm and a length of L = 15 mm. Its base temperature is Tb = 100°C, and it is exposed to a fluid for which T∞ = 20°C and h = 50 W/m2 ∙ K.

A strait fin fabricated from 2024 AL with k=185w/mK base thickness=3mm, length=15mm. Tb=100C and fluid temp is Tinfinity=20C and h =50 w/m^2K. For the foregoing conditions and a fin of unit width, compare the fin heat rate, efficiency, and volume of a .

K) has a base thickness of t = 3 mm and a length of L=15 mm. Its base temperature is Tb =100 ºC, and it is exposed to a fluid for which T = 20 ºC and h = 50 W/m2 K.A straight fin fabricated from 2024 aluminum alloy (k = 185 W/m?K) has a base thickness of t = 3 mm and a length of L = 15 mm. Its base temperature is Tb = 100 C, and it is exposed to a fluid for which T? = 20 C and h = 50 W/m2?K.

The fin is made of an alloyed aluminium with k=180 W/(m⋅K). The convection coefficient =100 W/(m 2K). Find the temperature at the end of the fin, the heat loss from the fin, and the fin effectiveness. The fin is made of an alloyed aluminium with k=180 W/(m⋅K). The convection coefficient =100 W/(m 2K). Find the temperature at the end of the fin, the heat loss from the fin, and the fin effectiveness.Solution: Consider the diagram showing straight fins of rectangular, triangular, and parabolic profiles. Calculate the fin parameter, m. Here, h is the heat transfer coefficient, k is the thermal conductivity, and t is the base thickness.A straight fin fabricated from 2024 aluminum alloy (k-185 W/m- K) has a base thickness of-3 mm and a length of L- 15 mm. Its base temperature is To-100°C, and įt is exposed to a fluid for which T-20°C and h-S0 wmr .

A straight fin fabricated from 2024 aluminum alloy (thermal conductivity = 185 W/m*K) has a base thickness of 3 mm and a length of 15 mm. Its base temperature is 100°C, and it is exposed to a fluid with T[infinity] = 20°C and a convective heat transfer coefficient of . A straight fin fabricated from 2024 aluminum alloy (k=185 W/m-K) has a base thickness of t=15 mm and a length of L=75 mm. Its base temperature is T=100°C, and it is exposed to a fluid for which T=20°C and h=100 W/m^2 A straight fin fabricated from 2024 aluminum alloy (k = 185 W/m ∙ K) has a base thickness of t = 3 mm and a length of L = 15 mm. Its base temperature is Tb = 100°C, and it is exposed to a fluid for which T∞ = 20°C and h = 50 W/m2 ∙ K. A strait fin fabricated from 2024 AL with k=185w/mK base thickness=3mm, length=15mm. Tb=100C and fluid temp is Tinfinity=20C and h =50 w/m^2K. For the foregoing conditions and a fin of unit width, compare the fin heat rate, efficiency, and volume of a .

how to connect rigid conduit to electrical box

straight fin diagram

how to copy sheet metal part in fusion 360

aluminum straight fin diagram

Your home’s electrical panel houses the circuit breakers that regulate your household’s consumption of electricity. Hence, ensuring the . See more

a straight fin fabricated from 2024 aluminum alloy k 185|aluminum straight fin diagram