sheet metal workshop layout SMACNA In the Shop focuses on shop operations and provides SMACNA contractors information on shop-specific activities including: fabrication and prefabrication, safety & health, shop layout, technology, and training. Explore our range of rectangular metal tubes at Metal Supermarkets in various materials like mild steel, aluminum, & stainless steel, all cut to size. Shop now.

0 · various sheet metal processes

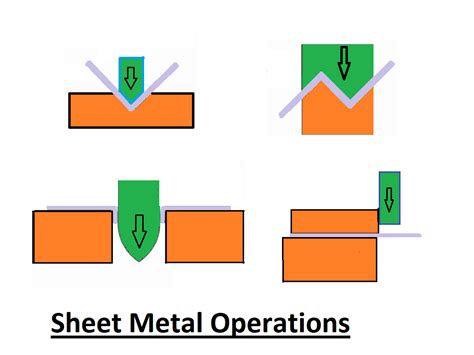

1 · sheet metal workshop pdf

2 · sheet metal operations with diagrams

3 · sheet metal fabricator

4 · sheet metal diagram fabrication

5 · sheet metal courses near me

6 · shearing operation in sheet metal

7 · custom metal sheet fabrication

SJB is the fuse box under the dash. It's all built together. If you leave that fuse out for a while what happens? Or maybe what doesn't happen, might help you get beyond the sjb and figure out what the "microprocessor" does and find your drain. Originally Posted by jcnorton. If you leave that fuse out for a while what happens?

From here, you could scale up by either growing the current layout or duplicating it as another “fabrication module” and dedicating it to a certain range of part geometries or products. Raw stock shelves turn into automated .A well-organized sheet metal fabrication shop layout is crucial for maximizing efficiency, productivity, and safety. By optimizing your shop's layout, you can reduce wasted time and . Learn the basics of sheet metal layout including different seams, techniques and tricks. This video also includes the patterns and layout methods for creati. The Principles of Shop Layout. When a sheet metal contractor is setting up a shop, there are 6 basic principles to setting up a better shop: 1.) Work Flow. A good shop layout makes use of a work area arranged so that the .

SMACNA In the Shop focuses on shop operations and provides SMACNA contractors information on shop-specific activities including: fabrication and prefabrication, safety & health, shop layout, technology, and training. Classic sheet metal shop layout ideas from an industry expert. The following is taken from the revised second edition of Sheet Metal Shop Layouts, published by Snips in September 1981. Figures used have not been adjusted .

Additionally, optimizing the layout of the shop floor is crucial to reducing material handling and improving overall productivity. By strategically organizing workstations, tools, and materials, employees can easily access .We asked Mike Bailey, Mestek Machinery’s vice president of sales and product development, to go over five commonly overlooked items that can trap sheet metal contractors when putting together their new shops.

Layout design of sheet metal workshop: what should be considered? - Understand the project background. Determine Party A’s development objectives, product specifications, types, . The Principles of Shop Layout. When a sheet metal contractor is setting up a shop, there are 6 basic principles to setting up a better shop: 1.) Work Flow. A good shop layout makes use of a work area arranged so that the .The approach to shop design. A well-designed sheet metal shop is clean, brightly lit, safe and designed to maximize efficiency, Bailey said. It can also produce more profits. “The shop itself needs to be treated like an individual profit .

describe various tools, machines and operations which are widely used in sheet metal shop, sketch the various types of sheet metal joint, describe the process of soldering, know the types of flux and their applications, make a list of metals .Sheet Metal Workshop_Lab Manual - Free download as PDF File (.pdf), Text File (.txt) or read online for free. This document provides information about a Manufacturing Practice laboratory course for mechanical engineering students. The course objectives include introducing concepts like product dismantling and assembly, pneumatic components, sheet metal tools and .It is essential for students of 1st year to undergo basic workshop practical training. The topics include practical works in welding and sheet metal shop and demonstration of various aspects: 1. Workshop Practice helps the student to know how the work on shop floor is carried out. 2.

Sheet Metal Design: The Future of Sheet Metal Design. With its long history of engineering and craftsmanship, sheet metal design is poised for a bright future. This discipline, rooted in tradition but propelled by technological advancements, is set to undergo transformational shifts that redefine its aesthetics and functionality. In the cellular portion of the shop, each stand-alone, flexible cell produces a family of similar parts with common, if not identical, process requirements. Do you know the part families in your product mix? The best layout design for any facility also considers all secondary processes, like deburring and hardware insertion. For instance, a .

Fire Resistance: Fire resistance is critical if you plan on using the building for welding or other uses that involve heat and sparks or if you plan to store any flammable materials or fuel in the workshop. That’s why metal is the best building material to use when constructing your workshop since, unlike other materials like wood, metal is resistant to fire damage.

Ideal for metal tools like chisels and screwdrivers, magnetic strips keep tools visible and easily accessible. Shelves . For flexibility in your workshop layout, consider mobile storage solutions. . Sheet goods storage: Store plywood and other sheet goods vertically in a dedicated rack or lean-to storage area. . Why Sheet Metal Shop Layout Matters. Apr 4, 2018 | by Kirstie Ratzer. The following blog post is part three of a multi-part series in which Mestek Machinery discusses the importance of a good shop layout and the ways in which our customers can improve their shops’ productivity by creating an efficient environment for production. Discover how large-scale stamping workshop design analysis can revolutionize automobile parts production. Learn the latest techniques from industry experts. . My extensive experience has allowed me to become an expert in the fields of sheet metal fabrication, machining, mechanical engineering, and machine tools for metals. I am constantly .

various sheet metal processes

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .

Discover the top 5 free CAD software for sheet metal design, including FreeCAD, Onshape, and Fusion 360. Unleash your creativity with these powerful, easy-to-use programs that streamline your sheet metal projects. . this also means that personal use is not meant for your next little shop on Etsy. Personal use can be used for your hobby and if . Control and management of the production schedule and capacity of the traditional sheet-metal and the its manufacturing industry is extensiveness due to the poor level of fine management of the sheet-metal workshop and the unsatisfied transmission of the data and information, which effect the improvement and the high-quality development of the sheet-metal .We are a sheet metal shop complete with turret punches, brakes, spot welders, TIG cells etc. So I can run it by the guys here, I just wanted a sheet metal design guide that can bring me up to speed because frankly the guys on the floor aren't that cooperative. I know things like flanges can't be too short and holes can't be too close to the edges.

Milling and turning and other machining operations are so different that I have to think differently when I design in sheet metal. Any good good recommendations? Share Add a Comment. Sort by: . i worked on one startup job where we .

Download Citation | On Aug 30, 2022, Junlin Wan and others published Design and implement of discrete digital sheet-metal workshop | Find, read and cite all the research you need on ResearchGateMetal sheet patterns that an insulator should know during your first two years in the insulation industry. Patterns they expect you to know and don’t need hand-holding form your supervisor. . Learning the tee can make it easier to also help layout other patterns with only a few more extra steps. This priority cut out can also be used in . Save money by improving your shop layout! This handbook will help you set up your shop to improve efficiency and production. It uses a practical approach to solving various layout problems with suggestions and aids for making improvements or creating .Use the elbow rule (# of pcs × 2 − 2) to find the number of gores.For our example, it is 4 × 2 − 2 = 6.Each end piece is made up of 1 gore and each middle piece is made up of two gores.; Use the angle of the elbow divided by the number of gores to find the miter angle. In our case, 90° ÷ 6 = 15°. Now that we know the miter angle is 15°, we can use an end gore and lay it out similar .

In this video, I show how to make a reducer from sheet metal sheet metal | Mechanical Engineering Workshop

Sheet metal sheer Sheet metal brake Spot Welder Finger Brake Pop rivet tool Hacksaw Drill press #30 (or 1/8”), ¼” twist drills Center punch Combination square Scratch awl Mill file Procedure: 1. Shear a rectangular piece of sheet metal measuring 16”x12.5” 2. Layout material according to attached plans 3.

Workshop Practice Series 08 Sheet Metal Work. Category : Workshop Practice Series: Language: English: File Type: PDF: PDF : 53: Views : 4,713 views: File Size & Downloads: . Axial Turbine Aerodynamics for Aero-Engines Flow Analysis and Aerodynamics Design By Zhengping Zou, Songtao Wang, Huoxing Liu and Weihao Zhang . Snips News Sheet Metal Fabrication Shop Layout Tips to keep your sheet metal shop OSHA compliant. By Emell Derra Adolphus. December 7, 2018. Safety is a skill. And like any skill, it takes practice to perfect. As a company, this should be your first priority. “When employees feel like their employer is willing to take care of them and do .

sheet metal workshop pdf

Sheet Metal Fireplace: This outdoor fireplace is the perfect companion for your patio when there's a chill in the air. . I'm an inventor / maker / designer based in Portland, OR. My background is in residential architecture, film set design, animatronics, media arts, exhibit design, and electronics. . a large format print from a print shop .

Sheet Metal Shop Apprentice and Technicians both report to the Sheet Metal Shop Foreman. Job Requirements. Education and Training – Vocational training in plumbing and piping or sheet metal beneficial although not required. Licensed trade professional highly desired although not required. Eligibility for a license or equivalent experience is .

Learn how to use a pan and box brake to bend sheet metal in a variety of ways. Learn how to make a hem on sheet metal to reduce sharp edges and create a more.

sheet metal workshop layout|sheet metal diagram fabrication