bending process in sheet metal pdf We want to construct the following Bending Moment “M” vs. curvature “1/ρ” curve. 5. After this point, the M vs 1/r curve starts to “bendover.” Note from M=0 to M=MY the curve is linear. . Junction boxes serve several important functions in electrical systems. Here are their primary purposes: 1. Protection of Electrical Connections. Junction boxes enclose and protect electrical connections from physical damage, dust, .

0 · sheet metal stamping process PDF

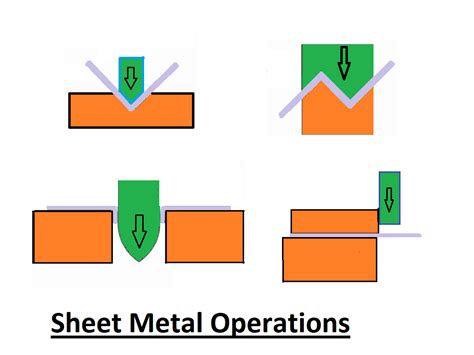

1 · sheet metal operations with diagrams

2 · sheet metal manufacturing process PDF

3 · sheet metal forming process PDF

4 · sheet metal fabrication handbook PDF

5 · sheet metal design calculations PDF

6 · sheet metal calculations PDF

7 · sheet metal calculation formula PDF

These charts show the average hourly wage (core compensation), as well as the average total hourly cash compensation for the job of Sheetmetal Fabricator I in the United States. The average hourly rate for Sheetmetal Fabricator I ranges from $17 to $23 with the average hourly pay of $19.

We want to construct the following Bending Moment “M” vs. curvature “1/ρ” curve. 5. After this point, the M vs 1/r curve starts to “bendover.” Note from M=0 to M=MY the curve is linear. .

Sheet bending is defined as the straining of the metal around a straight axis. During bending operation, the metal on the inner side of the neutral plane is compressed, and the metal on the .Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a .•Sheet metal processes involve plane stress loadings and lower forces than bulk forming •Almost all sheet metal forming is considered to be secondary processing •The main categories of .• Beading –bending the periphery of sheet metal into a cavity of a die to improve appearance and eliminate exposed edges • Flanging –bending edges of sheet metal to 90 degrees • Dimpling .

Bending is one very common sheet metal forming operation used not only to form shapes like seams, corrugations, and flanges but also to provide stiffness to the part (by increasing its .sheet metal forming processes. Bending, stretching and drawing of simple shapes are analysed, as are certain processes for forming thin-walled tubing. Where possible, the limits governing .

sheet metal stamping process PDF

Successful sheet-metal forming depends on the selection of a material with adequate formability, the proper design of the part and the tooling, the surface condition of the sheet, the selection .sheet metal parts where small bend radius is required. PROs: no springback higher precision smaller bending radius CONs: different tool set for each angle/shape higher tonnage (5 times .Bend Radius - As a rule, inside bend radius should be equal to material thickness. When the radius is less than recommended, this can cause material flow problems in soft material and fracturing in hard material. Bend Relief - When a bend is made close to an edge the material may tear unless bend relief is given. Figure "A" shows a torn part.

We want to construct the following Bending Moment “M” vs. curvature “1/ρ” curve. 5. After this point, the M vs 1/r curve starts to “bendover.” Note from M=0 to M=MY the curve is linear. Where εY is the strain at yield. Also since the strain at y Y is -εY, we can write. ( !" − 4 R $ ! (13) 0 % hE "Sheet bending is defined as the straining of the metal around a straight axis. During bending operation, the metal on the inner side of the neutral plane is compressed, and the metal on the outer side of the neutral plane is stretched. Bending .Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut a flat pattern, which can be formed .•Sheet metal processes involve plane stress loadings and lower forces than bulk forming •Almost all sheet metal forming is considered to be secondary processing •The main categories of sheet metal forming are: –Shearing –Bending –Drawing

• Beading –bending the periphery of sheet metal into a cavity of a die to improve appearance and eliminate exposed edges • Flanging –bending edges of sheet metal to 90 degrees • Dimpling –punching a hole, followed immediately by flanging the edges • Hemming –folding the edge of a sheet over itself

Bending is one very common sheet metal forming operation used not only to form shapes like seams, corrugations, and flanges but also to provide stiffness to the part (by increasing its moment of inertia).sheet metal forming processes. Bending, stretching and drawing of simple shapes are analysed, as are certain processes for forming thin-walled tubing. Where possible, the limits governing each process are identified and this entails a detailed study of tensile instability in thin sheet.Successful sheet-metal forming depends on the selection of a material with adequate formability, the proper design of the part and the tooling, the surface condition of the sheet, the selection and application of lubricants, and the speed of the forming press.sheet metal parts where small bend radius is required. PROs: no springback higher precision smaller bending radius CONs: different tool set for each angle/shape higher tonnage (5 times more than air bending) HEMMING (flattening) It is a 2-step process: - a 26'-3S pre-bend (by air bending process)

Bend Radius - As a rule, inside bend radius should be equal to material thickness. When the radius is less than recommended, this can cause material flow problems in soft material and fracturing in hard material. Bend Relief - When a bend is made close to an edge the material may tear unless bend relief is given. Figure "A" shows a torn part.We want to construct the following Bending Moment “M” vs. curvature “1/ρ” curve. 5. After this point, the M vs 1/r curve starts to “bendover.” Note from M=0 to M=MY the curve is linear. Where εY is the strain at yield. Also since the strain at y Y is -εY, we can write. ( !" − 4 R $ ! (13) 0 % hE "

Sheet bending is defined as the straining of the metal around a straight axis. During bending operation, the metal on the inner side of the neutral plane is compressed, and the metal on the outer side of the neutral plane is stretched. Bending .Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut a flat pattern, which can be formed .•Sheet metal processes involve plane stress loadings and lower forces than bulk forming •Almost all sheet metal forming is considered to be secondary processing •The main categories of sheet metal forming are: –Shearing –Bending –Drawing• Beading –bending the periphery of sheet metal into a cavity of a die to improve appearance and eliminate exposed edges • Flanging –bending edges of sheet metal to 90 degrees • Dimpling –punching a hole, followed immediately by flanging the edges • Hemming –folding the edge of a sheet over itself

Bending is one very common sheet metal forming operation used not only to form shapes like seams, corrugations, and flanges but also to provide stiffness to the part (by increasing its moment of inertia).

sheet metal forming processes. Bending, stretching and drawing of simple shapes are analysed, as are certain processes for forming thin-walled tubing. Where possible, the limits governing each process are identified and this entails a detailed study of tensile instability in thin sheet.Successful sheet-metal forming depends on the selection of a material with adequate formability, the proper design of the part and the tooling, the surface condition of the sheet, the selection and application of lubricants, and the speed of the forming press.

sheet metal operations with diagrams

LBY 40pcs Picture Frame L Shape Angle Bracket Flat Plate Fastener, Metal Picture Frame Hardware Corner Gasket, Corner Brace Joint Bracket Fastener,Joints Support Bracket,Silver Visit the LBY Store 4.6 4.6 out of 5 stars 72 ratings

bending process in sheet metal pdf|sheet metal calculations PDF