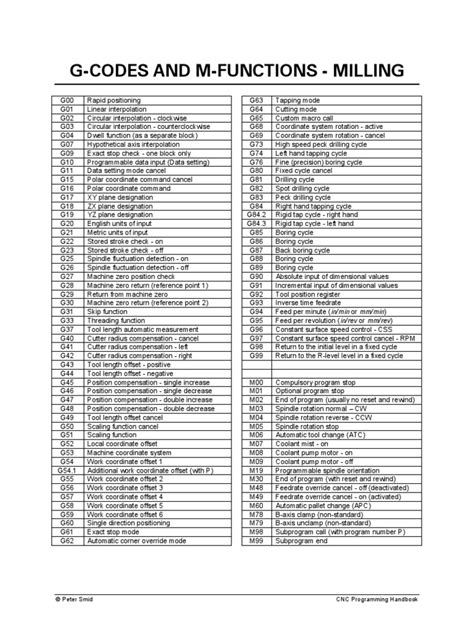

cnc machine m code and g code Every G code command sorted by how often they are used and organized by code type to make learning G code quick and simple.

Plastic - Installation material - WISKA - WISKA is your expert for installation .

0 · printable g codes and m

1 · g m codes cnc list

2 · g codes and m pdf

3 · g code and m chart

4 · g and m codes explained

5 · g and m code sheet

6 · g and m code cheat sheet

7 · cnc g code and m list pdf

$5.00

CNC G-codes & M Codes for milling and turning with explanations, syntax and program examples. (Full list and guide)N10 G90 (Setting Absolute mode); N20 G00 X1.0 Y1.0 (Position the machine at [P1]); .How to Apply G-codes relating to cutter compensation. Including Milling, .

In this article, we will navigate through the complexities of CNC programming by offering a detailed G-Code and M-Code reference. Our exploration will include codes that are pivotal for operations such as G00 for . Explore G and M codes for CNC machining, including definitions, uses, key commands, and practical applications in modern manufacturing. Every G code command sorted by how often they are used and organized by code type to make learning G code quick and simple.Learn everything about G-code and M-code, essential languages for CNC machine operations. Our comprehensive guide covers basic structures, common commands, examples, and the role of AI in CNC programming.

G-Code is the most common programming language. A G-Code in CNC Programming works like a controller and dictator. It controls the machine’s movement and dictates how and where it should move to formulate the end .

printable g codes and m

In CNC machining, G-codes and M-codes are two fundamental programming commands used to control the movement and functionality of machine tools. G-code, also known as “geometric code” or “preparatory code,” . G-codes and M-codes serve distinct but complementary roles in controlling CNC machines. Here’s a summary of their key differences: G-code focuses on commands related to .Simply put, G-code is a software programming language used to control a CNC machine. And, even with complex CNC machining, G-code is written in a straightforward, logical way. A “ G ” is followed by a number, which is a .CNC G-codes & M Codes for milling and turning with explanations, syntax and program examples. (Full list and guide)

In this article, we will navigate through the complexities of CNC programming by offering a detailed G-Code and M-Code reference. Our exploration will include codes that are pivotal for operations such as G00 for Rapid Positioning, G01 for Linear Interpolation, through to specific functionalities like G17 for XY Plane Selection, and system .

g m codes cnc list

Explore G and M codes for CNC machining, including definitions, uses, key commands, and practical applications in modern manufacturing. At the heart of CNC machining’s unmatched efficiency and accuracy are the G and M codes – the critical programming languages that guide CNC machines. Unlike common perception, G codes and M codes hold distinct roles in CNC operations.

Every G code command sorted by how often they are used and organized by code type to make learning G code quick and simple.

Learn everything about G-code and M-code, essential languages for CNC machine operations. Our comprehensive guide covers basic structures, common commands, examples, and the role of AI in CNC programming. G-Code is the most common programming language. A G-Code in CNC Programming works like a controller and dictator. It controls the machine’s movement and dictates how and where it should move to formulate the end CNC machined product. M-Code is used for specific applications.

In CNC machining, G-codes and M-codes are two fundamental programming commands used to control the movement and functionality of machine tools. G-code, also known as “geometric code” or “preparatory code,” is primarily used to define the motion and positioning of the cutting tool. G-codes and M-codes serve distinct but complementary roles in controlling CNC machines. Here’s a summary of their key differences: G-code focuses on commands related to tool movement, governing how the machine operates, including the cutting path and speed.Simply put, G-code is a software programming language used to control a CNC machine. And, even with complex CNC machining, G-code is written in a straightforward, logical way. A “ G ” is followed by a number, which is a command to change geometry. For instance, “G00” is a command for rapid movement.

stainless steel cabinet pul out shelves

CNC G-codes & M Codes for milling and turning with explanations, syntax and program examples. (Full list and guide) In this article, we will navigate through the complexities of CNC programming by offering a detailed G-Code and M-Code reference. Our exploration will include codes that are pivotal for operations such as G00 for Rapid Positioning, G01 for Linear Interpolation, through to specific functionalities like G17 for XY Plane Selection, and system .

Explore G and M codes for CNC machining, including definitions, uses, key commands, and practical applications in modern manufacturing. At the heart of CNC machining’s unmatched efficiency and accuracy are the G and M codes – the critical programming languages that guide CNC machines. Unlike common perception, G codes and M codes hold distinct roles in CNC operations. Every G code command sorted by how often they are used and organized by code type to make learning G code quick and simple.

Learn everything about G-code and M-code, essential languages for CNC machine operations. Our comprehensive guide covers basic structures, common commands, examples, and the role of AI in CNC programming. G-Code is the most common programming language. A G-Code in CNC Programming works like a controller and dictator. It controls the machine’s movement and dictates how and where it should move to formulate the end CNC machined product. M-Code is used for specific applications. In CNC machining, G-codes and M-codes are two fundamental programming commands used to control the movement and functionality of machine tools. G-code, also known as “geometric code” or “preparatory code,” is primarily used to define the motion and positioning of the cutting tool. G-codes and M-codes serve distinct but complementary roles in controlling CNC machines. Here’s a summary of their key differences: G-code focuses on commands related to tool movement, governing how the machine operates, including the cutting path and speed.

stainless steel cabinet magnets

g codes and m pdf

Buy WISKA Combi Series Black Polypropylene Junction Box, IP66, 85 x 85 x 51mm 60580. Browse our latest Junction Boxes offers. Free Next Day Delivery available.

cnc machine m code and g code|g codes and m pdf