3 5 axis cnc milling machines usages 3-axis CNC machining is also the cheapest and is mainly used to make parts that don’t require much detail work, for example, you can drill holes, cut sharp edges, tap holes, flatten surfaces and mill slots, etc. Use to provide safe, cost-effective access to underground services such as electric, water, gas, fiber optics, and traffic signals. The lightweight material is corrosion resistant, nonflammable, nonconductive, and stable under freeze/thaw conditions.

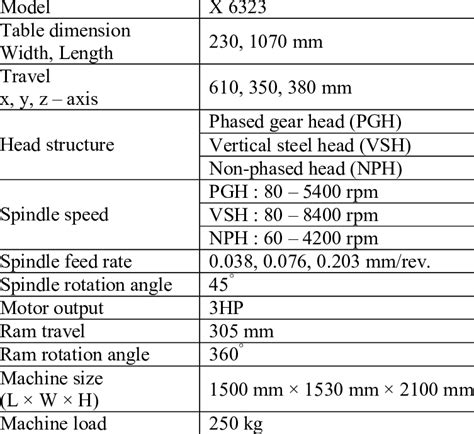

0 · specifications of cnc milling machine

1 · small 3 axis cnc mill

2 · datron cnc price list

3 · axis identification in cnc machine

4 · 3 axis vertical milling machine

5 · 3 axis manual milling machine

6 · 3 axis cnc table

7 · 3 axis cnc machine price

• Connect multiple fountain lights to a single power supply with these bronze junction boxes. • Available in two sizes - four or eight outlet. • Also available with solid bottom or a built-in 1" threaded inlet in bottom which can thread onto BWF10 bronze flange (below), once installed fill with junction box potting compound (sold separately)Find Weatherproof junction boxes at Lowe's today. Shop junction boxes and a variety of electrical products online at Lowes.com.

Understand the unique advantages of 3-axis, 4-axis, and 5-axis CNC machining for your projects. Learn how each configuration impacts precision, design complexity, and cost, with expert insights to help you select the ideal setup for applications from simple parts to intricate aerospace . 3-Axis vs. 5-Axis: Pros and Cons. The main difference between these two types of CNC machines is the number of ways they can move their tool: one has three, and one has five. This seemingly small factor, however, makes .

In a 3-axis machine, tools can move in three directions: i-e, X, Y, and Z. The 5-axis CNC machines allow the tools to move in five directions or axes. The tools’ X, Y, and axis movement is standard in both machines. . 3-axis CNC machining is also the cheapest and is mainly used to make parts that don’t require much detail work, for example, you can drill holes, cut sharp edges, tap holes, flatten surfaces and mill slots, etc.Both 3-axis and 5-axis CNC machines have their place in modern manufacturing, offering unique advantages depending on the application. While 3-axis machines are ideal for simpler tasks .

3-axis, 4-axis, and 5-axis CNC machines use the same fundamental technology. However, they have vast differences in terms of capabilities. Axes of Movement: The movement axes are the primary differentiating factor between . The main difference between 3-axis, 4-axis and 5-axis machining is the complexity of the movement both the workpiece and the cutting tool can move through, relative to each other. The more complex the motion of the two . In the automotive industry, 3-axis CNC milling machines can manufacture parts like engine components or custom modifications with high precision. They ensure consistency and quality, which are vital in this industry, .

We use 3-axis machines every day for a variety of milling operations. They’re great for fast and efficient material removal and for making flat or planar surfaces. These geometrical shapes are called prismatic, basically . Three axis CNC machining has significant advantages, making it highly favored in the manufacturing industry. Firstly, it is capable of completing complex cutting, drilling, and .

Understand the unique advantages of 3-axis, 4-axis, and 5-axis CNC machining for your projects. Learn how each configuration impacts precision, design complexity, and cost, with expert insights to help you select the ideal setup for applications from simple parts to . 3-Axis vs. 5-Axis: Pros and Cons. The main difference between these two types of CNC machines is the number of ways they can move their tool: one has three, and one has five. This seemingly small factor, however, makes a world of difference, as you can see in the side-by-side comparison table below. In a 3-axis machine, tools can move in three directions: i-e, X, Y, and Z. The 5-axis CNC machines allow the tools to move in five directions or axes. The tools’ X, Y, and axis movement is standard in both machines. However, tilting and rotational movement are additional in 5-axis CNC machines.

specifications of cnc milling machine

3-axis CNC machining is also the cheapest and is mainly used to make parts that don’t require much detail work, for example, you can drill holes, cut sharp edges, tap holes, flatten surfaces and mill slots, etc.Both 3-axis and 5-axis CNC machines have their place in modern manufacturing, offering unique advantages depending on the application. While 3-axis machines are ideal for simpler tasks and offer cost savings, 5-axis machines excel in producing complex parts .

custom made stainless steel cabinet pulls

3-axis, 4-axis, and 5-axis CNC machines use the same fundamental technology. However, they have vast differences in terms of capabilities. Axes of Movement: The movement axes are the primary differentiating factor between the 3, 4, and 5-axis CNC machining. The degree of axes is the direction a cutting tool can move. The main difference between 3-axis, 4-axis and 5-axis machining is the complexity of the movement both the workpiece and the cutting tool can move through, relative to each other. The more complex the motion of the two parts, the more complex the geometry of the final machined part can be.

In the automotive industry, 3-axis CNC milling machines can manufacture parts like engine components or custom modifications with high precision. They ensure consistency and quality, which are vital in this industry, where a small error can lead to catastrophic consequences. We use 3-axis machines every day for a variety of milling operations. They’re great for fast and efficient material removal and for making flat or planar surfaces. These geometrical shapes are called prismatic, basically rectilinear, as opposed to more organic, rounded shapes.

small 3 axis cnc mill

datron cnc price list

Sheet Metal Workers Local 17 1157 Adams Street Dorchester, MA 02124 (617) 296-1680. Contact

3 5 axis cnc milling machines usages|specifications of cnc milling machine